One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

This article mainly explains the square tube laser cutting machine to you, please continue to read the following article.

The fiber laser cutter price above is about USD 25,000-90,000. The brand, power size, configuration, and after-sales service also have a great impact on the laser cutter machine price.

If you want to buy an affordable price, you need to compare with multiple companies

It can cut stainless steel, carbon steel, copper, aluminum and other metal pipes.

It can cut common pipes such as round pipes, square pipes,rectangular tube and ovals, as well as various types of steel and special-shaped pipes such as angle steel, channel steel, I-beam, and H-beam.

We have a professional design team, and it is possible to customize the laser cutting tube drawing design, size, size and power of your product.

Polyethene cannot be cut, and harmful smoke will be produced, which will cause harm to the body of the operator and the laser pipe cutting machine itself.

The laser cutting square tube is suitable for polycarbonate below 1mm, and it will also cause the colour of the raw material to fade.

The high-energy temperature generated by the laser can volatilize raw materials, but it is not suitable for related materials such as ABS and polyethene plastics.

Cutting polyethene and polypropylene foam with a laser tube cutter is prone to fire.

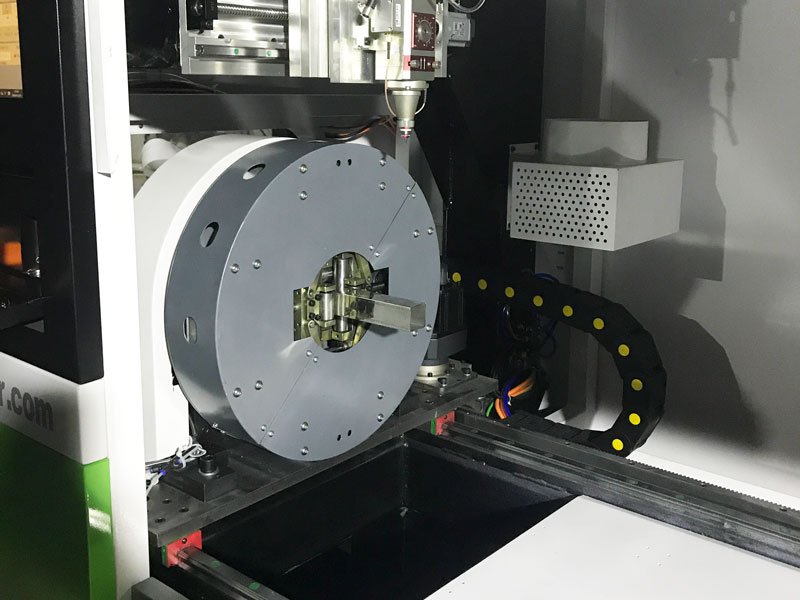

The laser cutting chuck can be adjusted manually and automatically and can be operated automatically only by operating the button. The holding force is stable and efficient, and the size is adjustable.

Reduce cumbersome manual procedures; one person operates multiple devices, increases work efficiency by five times, and batch processing is possible.

There is no need to rotate the cylinder, and it is equipped with a chuck and a gyrator. Compared with the traditional chuck, the structure is simpler, the installation is convenient, the load on the spindle is reduced, and the machine’s life is extended.

The chuck is a fully enclosed structure, and its service life is much higher than manual chucks. The life span can reach five years. The clamping accuracy is generally 0.01-0.03 mm, and the limit speed is 3000 rpm.

With a self-locking function, the workpiece can be firmly clamped for cutting when the power is off, which solves the safety problem.

Solution: Check whether the mainboard parameters are correct, stop the machine and check the mainboard parameter settings

Solution: Unplug the motherboard sensor; if the machine does not move, if it moves, replace it with a new sensor.

Solution: Check whether the motor wire or the motor shaft is broken, and if so, replace the motor wire or small motor.

Solution: Check the motherboard parameters, whether the X-axis or Y-axis can stop; if correct, check the motherboard or sensor, replace and rule out.

DOWELL Laser has 13 years of experience manufacturing laser cutting equipment, one-stop laser cutting solutions, and pipe laser cutting equipment for cutting round, square, rectangular, and channel steel. The company has a standard production process, and each department has dedicated personnel responsible. The machine is tested before delivery to ensure that it can be used normally when you receive it.

Do You Want to Buy the best square tube laser cutting machine? Fill Out This Form To Get In Touch.

Get the latest high quality square tube cutting machine laser price and product catalogue

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.