At present, the tube laser cutting machine price on the market is between 25,000-160,000 US dollars. This article will discuss in depth the functions and application scope of the cnc fiber laser tube cutting machine.

At present, there are many types of tube cutting laser machines on the market. Faced with so many types and power, how to choose. If you want to find a tube laser cutting services with a reasonable price, then this article is more suitable for you. Start reading now.

What Is a Fiber Laser Tube Cutting Machine?

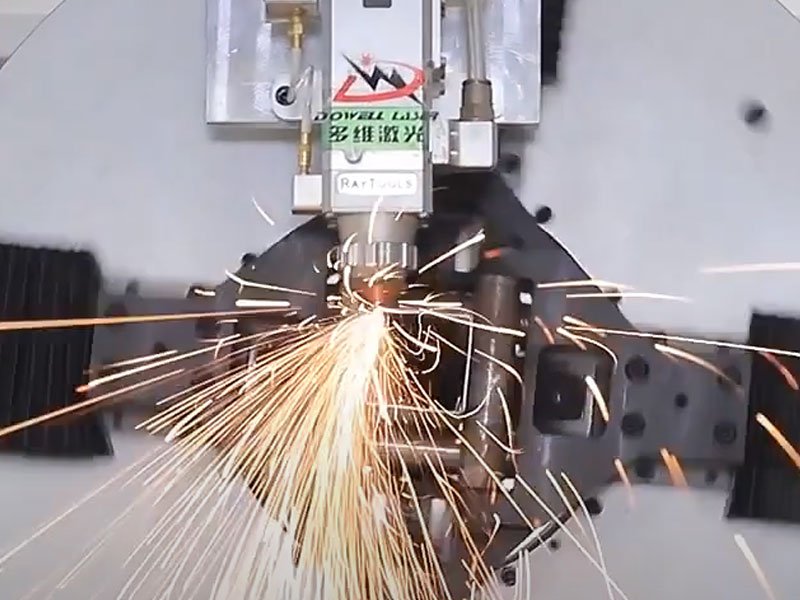

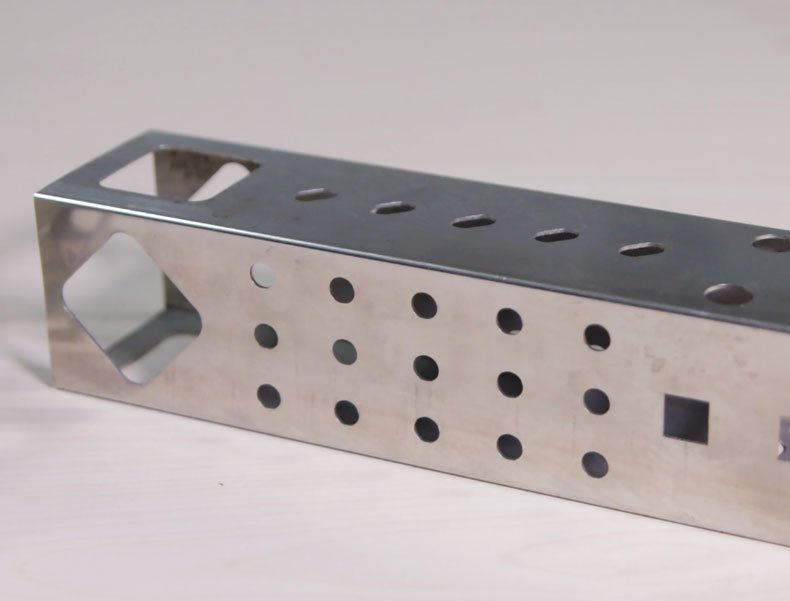

Laser pipe cutting is mainly used in industry. It is a kind of CNC cutting equipment for efficient cutting of metal pipes. It can cut various patterns on various pipes, bevel cutting and hollowing out holes with high precision. CNC laser cutting equipment with fast speed, labor saving and high work efficiency.

It can cut square pipe, round pipe, channel steel, angle steel, and the material of the pipe can be stainless steel, carbon steel, aluminum, alloy steel, brass and other materials.

Factors affecting laser pipe cutting machine price

Because the laser power, material, pipe diameter and configuration of the cut pipe are different, the price of each manufacturer is different. If you want to choose the equipment with the right laser pipe cutting machine price, you need to distinguish carefully.

What are the components of the tube laser cutter

The composition of the tube laser cutter: fiber laser, laser cutting head, CNC operating system, bed, water cooler, servo motor, beam, rack and pinion, etc.,

In addition, you can configure loading and unloading devices according to your own needs. This laser pipe cutting machine manufacturer can customize.

What are the types of tube laser cutting

- Economical tube laser cutting

- Three Chuck tube cutter laser

- Automatic loading and unloading laser pipe cutting machine

- Size: 6m 9m 12m can be customized according to customer needs of different sizes

What is the power of the fiber laser cutting machine tube

The power of the tube laser cutting services on the market at present; 1000w 1500w 2000w 3000w 6000w.

Which software we use for pipe cutting

The pipe laser cutting has nesting software, which can realize drawing, nesting, programming, calibration, nc output and other modes, and realize SolidWorks and CAD graphics cutting.

Pipe laser cutter VS traditional cutting

First of all, on the automatic pipe cutting production line, the focused laser beam must be synchronized with the pipe cutting;

Secondly, it is required that the focus of the focused laser can rotate one cycle relative to the pipe being cut, and the axis of the laser beam always intersects the axis of the pipe.

During the cutting process, the laser beam of the tube cutting line moves with the tube being cut.

These synchronous movements must be controlled by a special control system, so the research on the automatic production line of laser tube cutting is also of great significance.

Since the laser pipe cutting adopts a non-contact processing method, the pipe wall will not be under pressure during the entire processing process, and will not cause deformation or collapse of the pipe surface.

Compared with traditional processing equipment such as flame cutting, plasma cutting, and water cutting, the precision of laser cutting metal sheets is much higher.

FAQ

1.How does laser pipe cutting work?

Laser pipe cutting machine is the use of laser

2.How do I improve the laser tube cutter parts?

- Set up the correct cutting program and operate according to the correct process

- Reduce the cutting route to avoid repeated cutting.

- Strengthen the daily maintenance of metal tube laser cutter

3.How to maintain the laser of tube laser cutting services

- Before starting up, carefully check the pressure of the laser working gas and auxiliary gas Check that the cooling water pressure is kept between 3.5 and 5 Bar.

- Select the water temperature required by the laser.

- Check the oil level in the laser vacuum pump.

- Check whether there is any leakage in the laser oil circuit, water circuit, and gas circuit, and whether the pneumatic components and pipe joints of the vacuum pump and resonant cavity are leaking.

4.Front and back chuck synchronization process

The rear chuck is responsible for clamping the pipe to rotate and move back and forth. The other chuck is hollow and the four jaws are the structure of the roller, that is, the hollow chuck of the roller jaws, and the hollow chuck is close to the position for cutting

Summarize:

If you want to find a tube laser cutting machine manufacturer, it is best to first determine the size of the tube to be cut, the power of the laser cut tube needed, and what effect you want to cut out. In addition, it is best to go to tube laser cutting Machine manufacturers conduct on-the-spot inspections to compare the strength of the factory, production scale, after-sales service, etc.