With the popularization and development of metal furniture laser pipe cutter in the industrial market, the scope of application is more and more extensive. The iron furniture produced by the metal furniture industry for pipes and plates adds a lot of fun to our life.

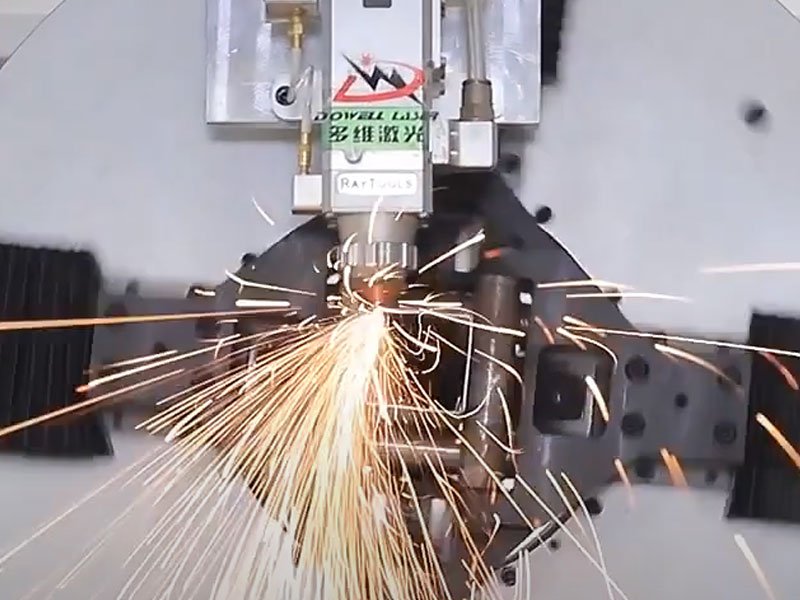

The traditional metal furniture industry manufacturing process is cumbersome, with 9 processes, and the labor cost required is relatively high. However, since the advent of laser cutting machine for metal furniture, cutting speed is fast and the cutting graphics are diversified. The key is to cut metal sheets with fast speed and no dross, which saves a lot of time.

1. The furniture laser pipe cutting machine has fast cutting speed and high precision, input any picture, size and cutting depth to be cut

2. The cutting speed is faster and higher, which shortens the working time and reduces the tedious traditional craft

3. The efficiency is increased by 5 times, saving more time, thus saving costs for business owners

4. There is no need for secondary grinding, which can greatly save labor and cost for furniture manufacturers

Metal furniture needs to cut a large number of metal pipes and plates, and then combine them with wood, various wood-based panels, stone or glass to form metal furniture.It is very popular in public places such as homes, hotels, stations, airports, canteens, restaurants, hospital furniture, medical beds and other medical equipment.

Among metal furniture, we should focus on stainless steel furniture, which is also the most popular type of product in metal furniture. Stainless steel furniture is mostly made of food-grade 304 stainless steel, which has strong corrosion resistance and a high degree of surface finish. Stainless steel has a long service life, no paint, no glue, no formaldehyde emission, and is an environmentally friendly furniture material.

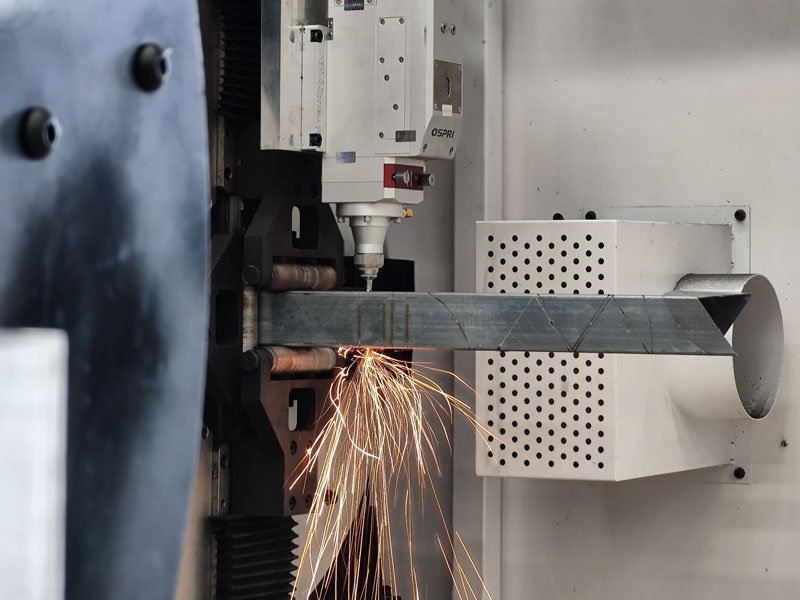

The most used plate in stainless steel furniture is less than 3mm thick, and the thickness of the pipe is less than 1.5mm, basically it can be realized with a 2kw fiber laser cutting machine.

The production process of traditional stainless steel furniture: picking material – sawing machine cutting – lathe processing – processing inclined plane – drilling – proofing punching – drilling – cleaning – transfer welding, 9 processes are required.

In the production of stainless steel furniture, arc-shaped and curved parts are also involved, which need to be stamped and formed by molds, or bending and forming equipment. Then to the combination and splicing of complete sets of furniture, in addition to screws and fasteners, the connection of stainless steel parts is mostly welding technology.

Hand-held laser welding equipment, replacing many applications that originally used argon arc welding.

Because of its lightness and flexibility, strong adaptability, high efficiency, and stable welding, it is widely used, and the power is between 500 watts and 2000 watts.

Hand-held laser welding can solve the problem of traditional welding on stainless steel furniture. It is flexible and suitable for arc splicing and angle iron turning edge connection. It has good welding stability and does not require filler or specific gas. The preferred process for welding smaller stainless steel materials.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!