One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

The DOWELL tube and plate laser cutting machine can not only meet the requirements of customers for cutting flat plates but also meet the cutting of various-shaped tubes such as round tubes and square tubes.

The DOWELL metal tube sheet metal cutting machine uses a fiber laser to output a high-energy-density laser beam, which is focused on the surface of the workpiece to instantly melt and vaporize the area illuminated by the focal spot. The spot is automatically cut through the irradiation position of the CNC mechanical system. High-tech equipment integrating fiber laser technology, CNC technology, and precision machinery technology.

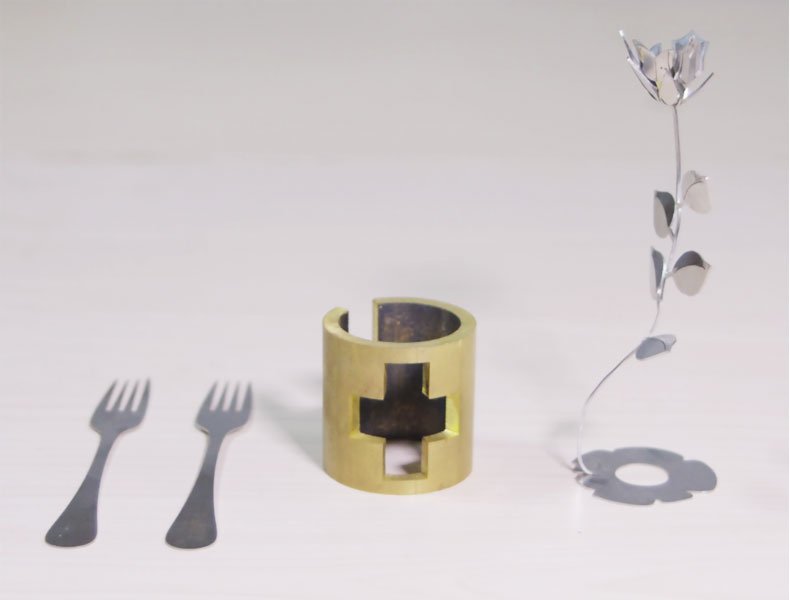

The plate and tube integrated cnc metal laser cutter can realize cutting on metal pipes, stainless steel pipes, aluminum alloy pipes, steel pipes, carbon steel pipes, alloy pipes, aluminum pipes, copper pipes, aluminum plates, stainless steel plates and other materials.

Rectangular tubes, flat tubes, U-shaped tubes and special-shaped tubes, etc. At the same time, cutting processes such as punching, oblique cutting, and micro-connection can be performed during cutting.

The dual purpose laser cutting machine for plates and tubes can not only meet the requirements of customers for cutting flat plates but also meet the cutting of various-shaped tubes such as round tubes and square tubes.

The unique fixed-grip design of the plate and tube dual-purpose laser cutting machine can test the rapid adjustment of different coffins, so as to achieve high-precision products during the reprocessing process.

The sheet and tube laser cutting machine tool is equipped with different professional chuck fixtures, which can be processed accurately for different shapes and sizes of pipes.

The dual-purpose cnc metal cutting for plates and tubes can process square tubes, round tubes, rectangular tubes, and round tubes that are common in the market, and can realize the function of importing plane drawing.

Rigorous process manufacturing and quality inspection of fiber metal sheet cutting machine

1. Each machine tool is finely welded and spliced to make the machine tool stronger

2. Each steel plate welding machine tool is subjected to high-temperature heat treatment to eliminate stress

3. The machine tool after the annealing process is finished by gantry center milling

4. Each machine tool is controlled as a whole to maintain the stability of long-term work

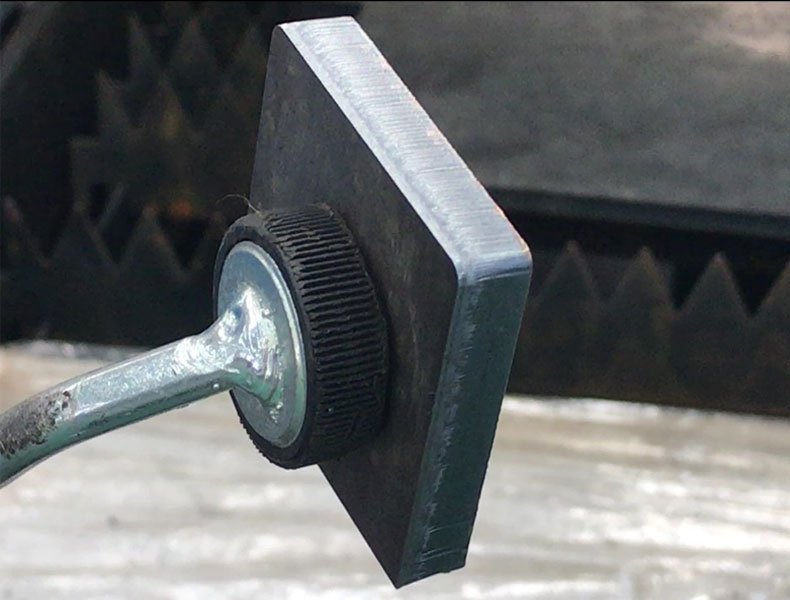

5. Every screw on the machine tool is strictly installed according to the standard, and the torque is locked

6. Each rack screw point is spliced with two racks, and the accuracy of the position is controlled within 0.01MM

7. Make the X-axis and Y-axis vertical accuracy error control within 0.01MM

8. After installation and debugging, the equipment uses a laser interferometer for secondary calibration, detection, and accuracy compensation

9. Before leaving the factory, the equipment must undergo continuous 72 hours of machine test and strict testing

The installer is composing the lazer cutting machine

Workers are installing lazer cutting machinelines

The assembler carefully assembles the fiber laser cut machines equipment

Provide you with proofing and cutting services for free, we will live video broadcast with you in the factory, you can see the cutting process and results, or send samples to you

According to your product processing requirements, we provide you with unique product solutions to improve production efficiency and better processing quality.

According to the customer’s application, we may modify our machine according to the customer’s convenience and high production efficiency.

If there is a quality problem with the parts of the system during the warranty period, our company’s service engineer will provide telephone or on-site service at any time

Our company provides lifelong maintenance services for the products provided and provides equipment-related consultation and guidance at any time. After the warranty period, our company still provides customers with extensive and preferential technical support and spare parts supply.

After receiving the anti-expensive time, the effective time is 2 hours to communicate through telephone communication. After the equipment warranty expires, maintenance services will be provided for life.

Do You Want to Buy Plate and tube laser cutting machine? Fill Out This Form To Get In Touch.

Click Consult to get the metal tube and sheet laser cutting machine quotation

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.