One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

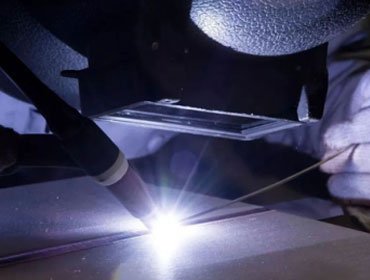

DOWELL 3 in 1 laser welding machine (laser welder cutter cleaner ) is a kind of laser welding, cleaning and cutting three technologies combined in one device, it is a relatively advanced laser technology at present, it can be used for multiple purposes, saving costs.

At present, 3in1 laser cutting and welding machine is widely used in kitchen utensils, machinery production, automobile manufacturing, ship industry and other industrial machinery production.

The 3 in 1 laser welding machine is designed to be user-friendly, with a simple and intuitive interface that allows for easy operation. It also has a compact design, making it ideal for small workshops and businesses.

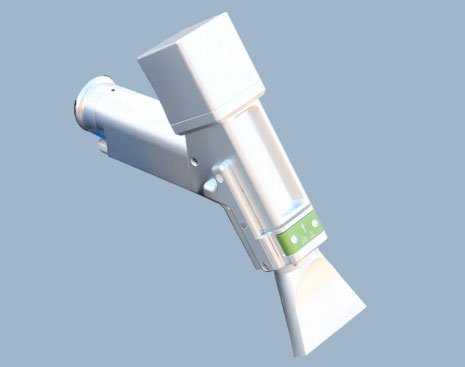

3 In 1 Laser Welder Cleaner Cutter control system, flexible switching of welding, cleaning and cutting, one device replaces the original three, taking into account efficiency and quality, powerful functions; all parameters are visible, real-time monitoring of the machine status, avoiding problems in advance, convenient for troubleshooting and solving problems, Make sure the system works stably

Power size:1000w 1500w 2000w 3 In 1 Handheld Laser Welding Machine

Power size: 3000w 3 In 1 handheld laser cutting and welding

You can start welding with simple training, no need for professional teachers and test certificates, etc., to achieve different The welding method of the same type of joint, the welding quality is good, and the workpiece is not deformed

3-5 times faster than traditional welding, each machine can save 2 welders per year on average, and the life of consumables is less Long, beautiful welds, no weld scars, reduce the cost of subsequent grinding treatment, safer and more environmentally friendly.

Dual swing welding torches, adjustable spot width, can perform various welding methods such as angle welding and wire feeding welding, which can be switched according to the actual situation.

The equipment is compact in size, which has obvious advantages. It is 780*width*380*580*height, and weighs 70KG.

It has multiple advantages such as simple operation, beautiful weld seam, fast welding speed, small size and convenient transportation.

In terms of welding metal materials such as thin stainless steel plates, iron plates, galvanized plates, and aluminum alloys, it can perfectly replace traditional argon arc welding, electric welding and other processes.

The operation is simple, the installation is convenient, and automation can be realized. It can be cleaned without chemical reagents, media, dust, and water when it is powered on, and can remove resin, paint, stains, dirt, rust, coatings, platings, and oxide layers on the surface of objects

Suitable for cutting a variety of materials, this is a versatile cutting tool.

High-speed laser cutting, small thermal reaction zone, smooth cut surface without deformation.

Kirin double-oscillating welding head, the welding head can automatically feed wire, and can realize spot, line, circle, circular triangle and eight-shaped welding, etc. Its unique wedge-shaped vibration mode widens the weld seam and makes the laser Welding applications are more extensive. For larger workpieces, workpieces with wider weld seams can achieve high-efficiency and precise laser welding, and the welding quality is significantly better than that of ordinary welding heads. The quality is better.

Consuming wire, the material needs to be pre-cleaned and beveled before fully penetrating thick metal. Due to the limited welding direction and operating angle, vertical welding is extremely challenging.

The welding seam has a shallow depth of penetration and a wide melting width. Only thin plates can be welded, and the deformation is large. High current will also cause melting and evaporation of the tungsten electrode. Manual wire filling is difficult and inefficient.

The operation is simple, the fusion is deep, the speed is fast, the weld seam is smooth and beautiful, the deformation is small, the subsequent grinding process is reduced, and beautiful products can be welded without a master.

High electro-optical conversion efficiency, can be used for cutting stainless steel, carbon steel, aluminum, copper and other metal materials

Do You Want to Buy Laser welder 3 in 1 Cleaner Cutter? Fill Out This Form To Get In Touch.

Contact us for the latest laser 3in1 welder quotes and product catalogs

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.