One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

Accurate and efficient to provide the most affordable brass fiber laser cutter price

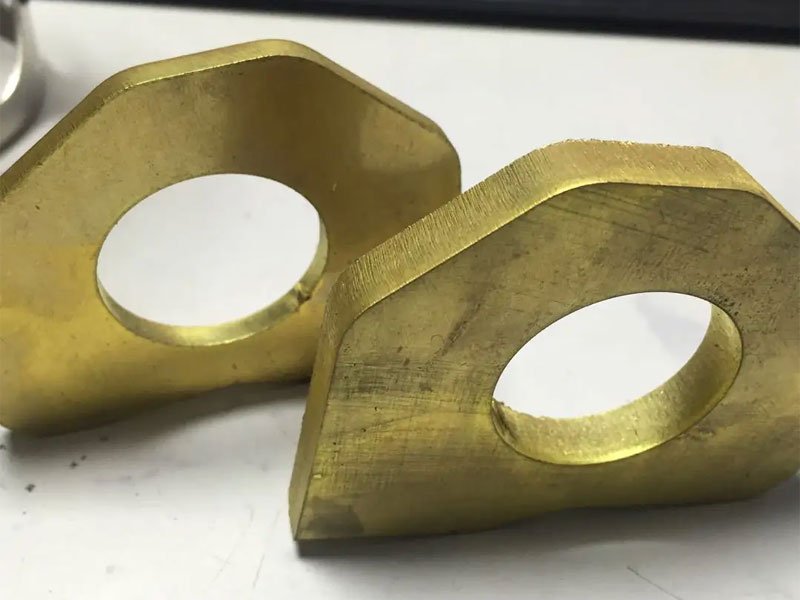

Laser cut brass sheet uses the high-energy light speed produced by the laser to quickly evaporate or melt the brass to achieve precise cutting. Not only can it be cut, but it can also be used for punching, lettering and more complicated precision cutting. It can be said It is a multi-purpose machine.

Laser cutting of copper plates is possible. Cutting brass with laser cutter faces two challenges. First of all, copper is a material with good thermal conductivity. The high thermal conductivity requires more laser power when cutting the copper plate, otherwise cracks will easily occur.

Copper is a very reflective metal and can easily reflect laser light, which will have a great impact on the cutting effect. Mastering the pulse parameters of the tunable pulse laser can make the laser penetrate the surface of metallic copper and reflect it to form a melting and cutting process.

By controlling the parameters such as laser power, frequency, pulse width and scanning speed, the brass fiber laser cutter is feasible and can achieve higher cutting quality and efficiency.

Laser cutting of copper plates is possible. Cutting brass with laser cutter faces two challenges. First of all, copper is a material with good thermal conductivity. The high thermal conductivity requires more laser power when cutting the copper plate, otherwise cracks will easily occur.

Laser cutting brass components for clocks and watches

Custom brass nameplates and signs

Intricate details and designs in brass jewelry

Brass musical instruments and the potential of laser cutting

Electrical components and shielding

Decorative inlays and furniture embellishments

We can provide the brass laser cutter price, free proofing, and delivery within 30 days. Pricing is based on selected configuration, wattage size, laser cutter table and brass laser cutting design. Click to the left for an instant quote.

We guarantee that the parts are of high quality and use high-end brands on the market. We provide you with the most competitive brass laser cutting machine price with high quality.

15 years of experience in laser equipment manufacturing, one of the most popular brass laser cutting machine factories in China, providing OEM ODM services.

Reflective metals are metals that reflect wavelengths directed toward them. Such as copper, brass, bronze, aluminum, gold, and silver are the most reflective, the latter can reflect about 95% of visible light. Reflective metals place obvious requirements on laser cutting processes involving laser beams of heat and light. Reflective metal can direct the light that hits it back to its source. This is called “tempering”. If you use a general laser cutting machine to cut forcibly, it will damage the equipment and cause huge losses.

The fiber laser cutting machine focuses the laser emitted from the laser into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece, causing the workpiece to reach the melting or boiling point, and at the same time, the high-pressure gas coaxial with the beam blows away the melted or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, thereby achieving the purpose of cutting.

Applying a non-reflective coating to the metal solves this problem. The molten metal created during laser cutting is itself reflective and will eventually damage the laser. There is also a self-protection system in the laser cutting machine. In the event of a reflection of the laser beam, the system will shut down the laser cutting machine to prevent damage to the lens.

The working principle of the gas (CO2) laser cutting machine is to make the heat of the laser beam fully absorbed by the material, and the reflective properties of the metal will cause the laser beam to be repelled. In this case, the reverse laser beam will enter through the head of the laser cutting machine’s lens and reflector system, causing damage to the machine.

Fiber laser cutting is the cutting edge technology that can effectively handle reflective metal cutting solutions. Fiber lasers use optical fibers that guide the laser beam, rather than using a complex system of mirrors. Fiber laser cutting does not use mirrors, gases, or precision lenses. Instead, it uses optical fiber to transmit the beam, which means that the reflective properties of metal do not cause damage to the laser like with gas or crystal lasers. Using a fiber laser cutting machine instead of carbon dioxide to cut reflective materials is the fastest and most cost-effective alternative.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.