Versatile Cutting Capabilities: These machines can handle tubes with diameters ranging from as small as 10 mm to as large as 520 mm, and lengths up to 12 meters or more, depending on the model. For example, the BLM GROUP Lasertube LT12 can cut tubes up to 305 mm in diameter and 12.5 meters long

Precision and Quality: The use of fiber lasers allows for smooth, burr-free cuts with minimal heat affected zones, which reduces the need for secondary operations such as grinding. This leads to faster production times and lower operational costs

3D Cutting Mode: Many machines offer a 3D cutting mode that enables the creation of complex geometries, including bevels at various angles (e.g., V/X/Y shapes). This feature is particularly beneficial for fabricators looking to create intricate designs without additional processing steps.

High Productivity: Machines like the TL 8525 from LVD Group are designed for high productivity with features such as automatic loaders and optimized cutting heads that maximize material usage.

Automation and Efficiency: Features such as automatic unloading systems and intelligent dust removal enhance operational efficiency by reducing manual intervention and maintenance requirements.

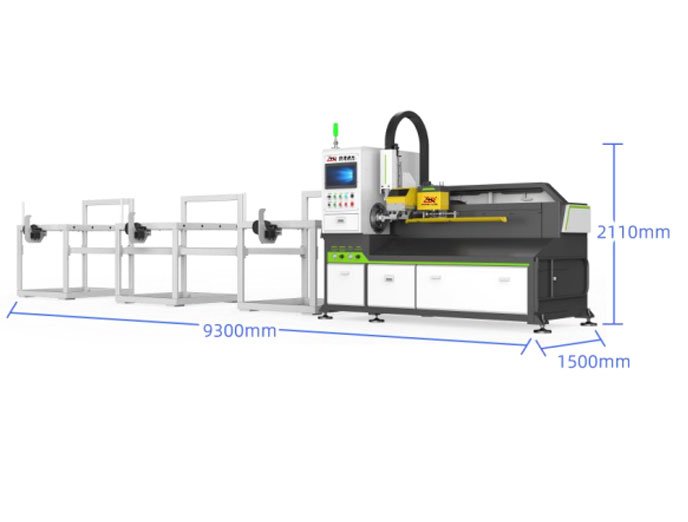

1. Strong versatility, speed and precision are at the advanced level in the industry, suitable for precision cutting in most industries

2. Acceleration ≤1.2G

3. Bochu system, Bochu nesting software

4. Cutting tube diameter range: round tube diameter 10-87mm/square tube 10*10-62*62mm

5. Matching laser range: 1000-3000W

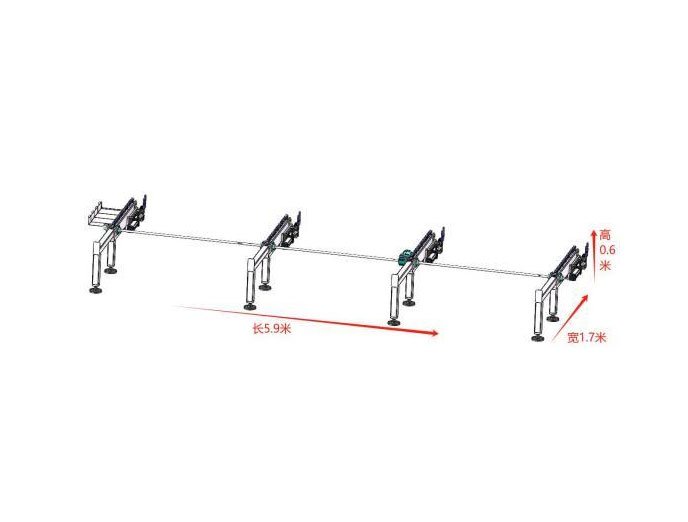

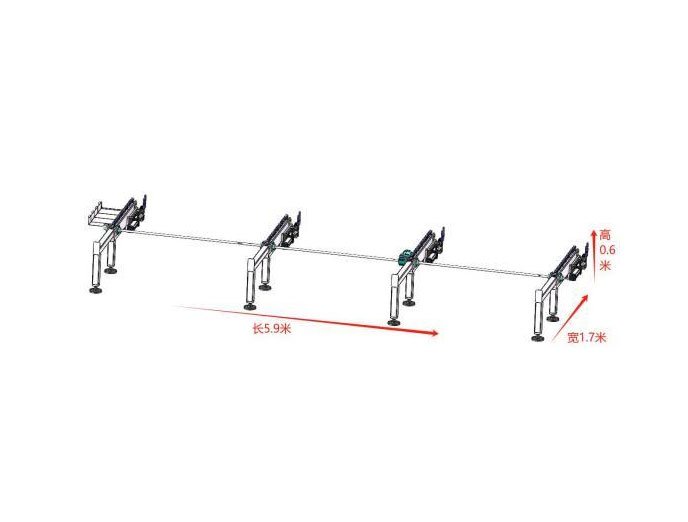

6. Equipped with fully automatic rack to save time and labor, simple structure and easy operation;

Semi-automatic feeding is suitable for round tubes, square tubes, rectangular tubes, runway tubes (10-87mm)

Just manually arrange 6 meters of raw materials into the storage rack, and arrange 10-30 tubes in sequence according to the size of the tube: manual arrangement → automatic feeding → automatic cutting → automatic blanking full process.

Manual feeding is suitable for round tubes, square tubes, flat tubes, U-shaped tubes, triangular square tubes (10-87mm

Just put 6 meters of raw materials into the storage rack in batches: manual feeding → automatic feeding → automatic cutting → automatic blanking full process

Suitable for round tubes, square tubes, rectangular tubes, runway tubes (tube diameter range: 10-87mm)

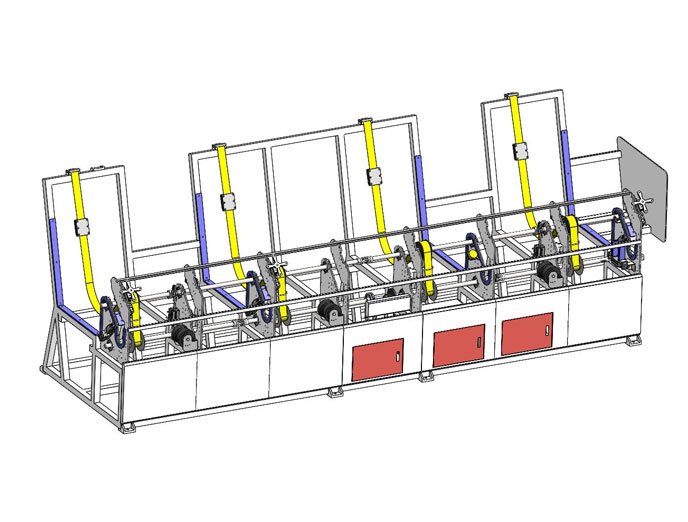

Fully automatic loading of whole bundles: Simply hoist 6 meters of raw materials into the storage rack in batches to achieve: automatic loading → automatic feeding → automatic

arrangement → automatic cutting → automatic blanking of the entire process.

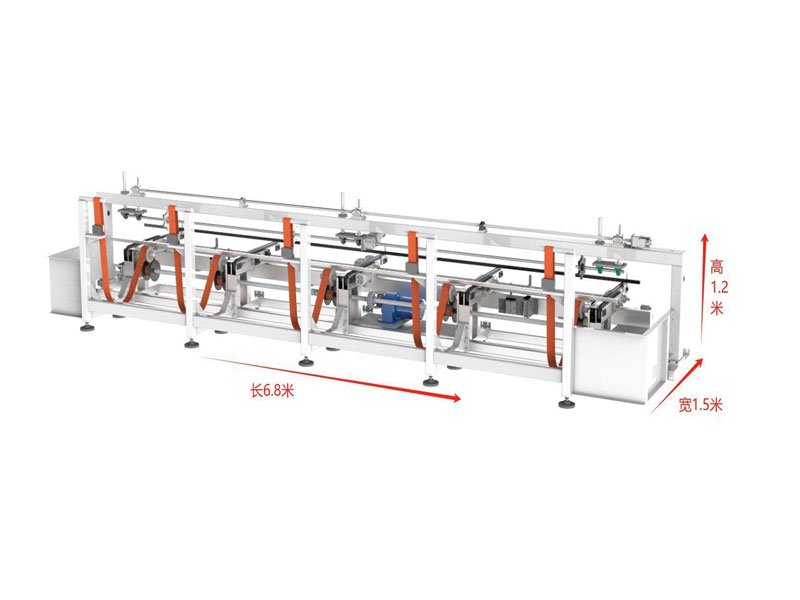

1. Small tube cutting tool, ultra-short tail material, ultra-fast acceleration;

2. Cutting tube diameter range: round tube: ∅ 10-120mm; square tube: ∅10×10-120x120mm;

3. Professional small tube cutting system: Bochu/Weihong (optional professional nesting software);

4. Laser power range: 1500-3000W;

Laser tube cutting machines are widely used in the manufacture of automotive parts such as doors, chassis and brake pads. Its high precision and high efficiency make the production process more reliable and significantly improve the safety and quality of products.

Laser tube cutting machines are used in the aerospace field to manufacture lightweight and high-strength structural parts, helping to improve the performance and safety of aircraft.

These machines are used to make steel structures and other metal components, providing flexible design options and efficient processing capabilities

The mechanization and integration of agriculture have promoted the great development of agricultural machinery. The high cost performance and technical flexibility of three-dimensional five-axis cutting machines are very suitable for the batch manufacturing and technological update of agricultural machinery, which is very popular among agricultural machinery manufacturers.

Do you want to know more about tube laser 3d cutting equipment now? You can tell us the material to be cut and the required power, and we will arrange for a professional engineer to contact you.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.