The metal tube laser cutting machine adopts imported special tube cutting software and has the core technology of efficient cutting, which is the fundamental guarantee for effectively saving materials and improving cutting efficiency.

Fiber laser technology tube adopts imported special tube cutting software, which is simple in operation, high in precision and strong in professionalism. It can cut round tubes, square tubes, shaped tubes and other tubes. It has the core technology of efficient cutting, which is effective in saving materials and improving cutting efficiency. Fundamental guarantee.

(1000 watts fiber laser cutting machine tube as an example, 1000-4000 watts can be customized)

The above data is for reference only, subject to the actual product

The cast iron bed has large mechanical quality, good stability and no vibration,

High cutting precision, good integrity, high-temperature quenching,

The bed is not deformed and has a long service life)

High performance-price ratio, service life up to 100,000 hours,

Good cutting effect and strong stability

(Optional Chuangxin, Ruike, IPG)

Raytools or WSX or imported Precitec

Internationally renowned brand, long service life, stable, high-cost performance

Taiwan Bank of China or PMI or import

Uniform force, improve machining accuracy and stability, and have a life span of up to 10 years

Fscut or Weihong can be selected

Simple operation, support a variety of CAD drawing recognition, stable model,

China’s well-known brands

Fast speed, save time, improve efficiency, large pneumatic clamping force to ensure cutting accuracy;

Special support frame to avoid sagging deformation and prolong the life of the chuck

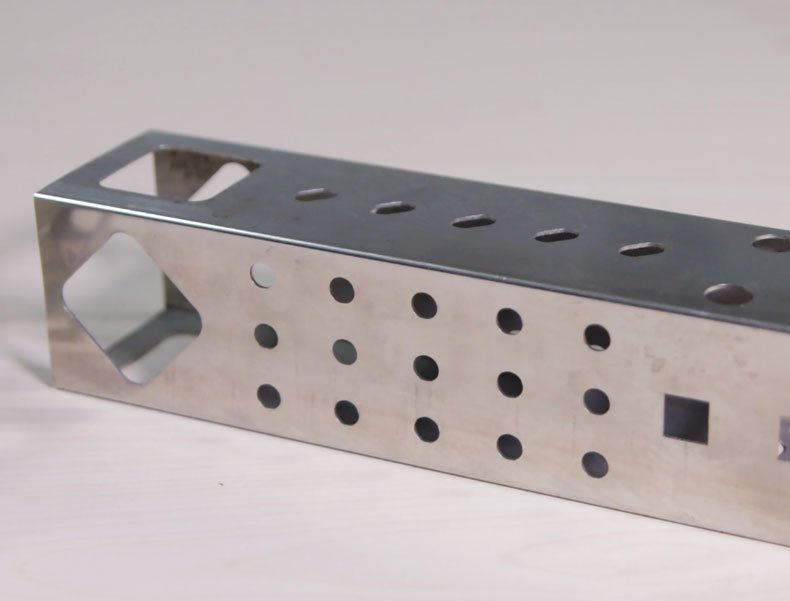

1. A plurality of cylindrical intersecting line holes with different directions and different diameters can be cut on the main pipe to meet the condition of the eccentric and non-eccentric vertical intersection of the branch pipe axis and the main pipe axis.

2. It can cut the end of the cylindrical intersecting line at the end of the branch pipe to meet the conditions of eccentric and non-eccentric vertical intersection and the oblique intersection of the branch pipe axis and the main pipe axis.

3. It can cut the beveled end face at the end of the round tube.

4. It can cut the end of the intersecting line of the branch pipe that intersects the ring main pipe.

5. Can cut variable-angle groove surface.

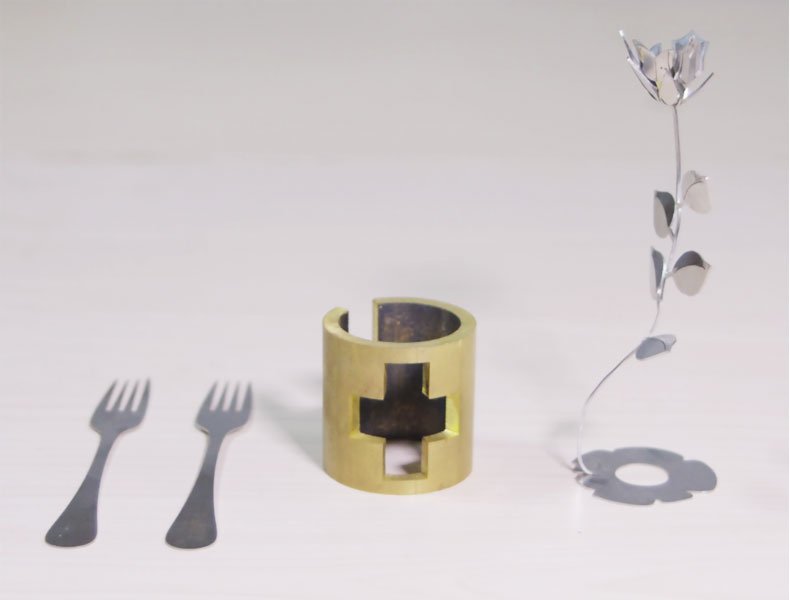

6. It can cut square holes and waist holes in round tubes.

7. The steel pipe can be cut off.

8. Can cut various graphics on the square tube surface.

The laser pipe cutting machine produced by DOWELL tube fiber laser cutting machine factory can cut metal round tubes, square tubes, special-shaped tubes, angle steel, channel steel, etc., suitable for metal pipes, stainless steel pipes, steel pipes, circular tubes, suitable for 20mm-200mm pipes , different sizes and power can be customized, the power of the machine is 1000w 1500w 2000w 3000w pipe, we can provide you with china affordable automatic tube laser cutting machine price

Used in sheet metal processing, aerospace, aviation, electronics, electrical, high-speed rail and subway accessories, auto parts processing, food machinery, textile machinery, engineering machinery, ships, metallurgical equipment, elevators, household appliances, kitchen supplies, tool processing, decoration, Advertising and other metal materials processing and manufacturing industries.

Industries such as aerospace, automotive, construction, and metal fabrication heavily rely on CNC laser tube cutting machines. These sectors demand high precision, consistency, and efficiency, which fiber laser technology readily provides. The machine is also used for manufacturing custom tube designs, particularly in areas where complex cuts are needed.

Professional technicians install the sheet metal of the machine and the precise installation of the rack and pinion to ensure the accuracy of metal tube laser cutting machine cutting

We have professional electrical department personnel to conduct circuit assembly test on steel tube laser cutting machine to ensure smooth circuit and normal operation of the machine

After the machine is assembled, professional technicians will conduct a cutting test on the equipment to ensure that customers receive the best tube laser cutting machine

Depending on the specifications and configuration of different equipment, the large tube laser cutter can achieve tube cutting ranging from 220mm to 1000mm. This means it is suitable for a variety of piping applications, including construction, Through high-precision cutting of laser beams, large-scale laser pipe cutting machines can achieve cutting needs of various shapes such as straight lines, curves, holes, etc.

The cutting accuracy of laser pipe cutting machines is usually between 0.1-0.5 mm, which can meet the requirements of high-precision cutting. Laser pipe cutting machine cutting dimensional accuracy

The power of fiber laser cutting machine tube is generally 1000w 1500w 2000w 3kw 4kw 6kw. Different factory manufacturers can also customize it.

Yes, the machine supports 3D tube cutting, making it suitable for industries requiring complex geometries, such as automotive or construction. The 3D cutting feature allows for multi-angle and multi-dimensional cuts, providing flexibility for intricate projects that require more than just standard straight cuts.

Yes, the machine can be tailored to fit specific pipe cutting technologies and applications. Whether you require specific fixtures or software adaptations for particular projects, the machine offers customization options to meet unique production needs. This flexibility makes it ideal for specialized metalwork.

Yes, the CNC laser tube cutting machine is scalable and can be used for both small-scale custom projects and large-scale industrial metal processing solutions. It offers flexibility in terms of batch size, making it an excellent investment for manufacturers of all sizes who require precision and efficiency.

Fiber laser technology offers significant advantages in tube cutting, including faster processing speeds, improved precision, and lower energy consumption compared to traditional methods. The accuracy of the laser ensures clean cuts, reducing the need for secondary finishing. It’s also more efficient for various materials, making it an ideal solution for industries like metal fabrication and automotive manufacturing.

Yes, the CNC laser tube cutting machine is highly versatile and can handle stainless steel, aluminum, carbon steel, copper, and other metals. Its ability to process a wide range of materials makes it an essential tool for metal processing solutions. Whether you’re working with thin or thick-walled tubes, the machine delivers precision and consistency.

The integration of CNC automation ensures that each cut is highly precise and repeatable, even for complex shapes or large batches. With automated adjustments, the machine can handle intricate designs while minimizing human error. This results in high-quality cuts, ideal for industries like aerospace or custom tube manufacturing.

This machine significantly boosts productivity with its high-speed laser cutting capabilities and minimal downtime. The fiber laser is faster than CO2 lasers and other cutting methods, enabling quick transitions between projects. It also reduces waste by making more accurate cuts, leading to cost savings in both materials and time.

The fiber laser in this cutting machine is designed for long-term use, often exceeding 100,000 hours of operational life with proper maintenance. Minimal upkeep is required compared to CO2 lasers, as fiber lasers have fewer consumable parts. Routine maintenance primarily involves cleaning optics and ensuring the machine’s software is updated.

Do You Want to Buy best tube laser cutting machine ? Fill Out This Form To Get In Touch.

Contact dowell cnc tube fiber laser cutting machine factories for latest product catalog

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!