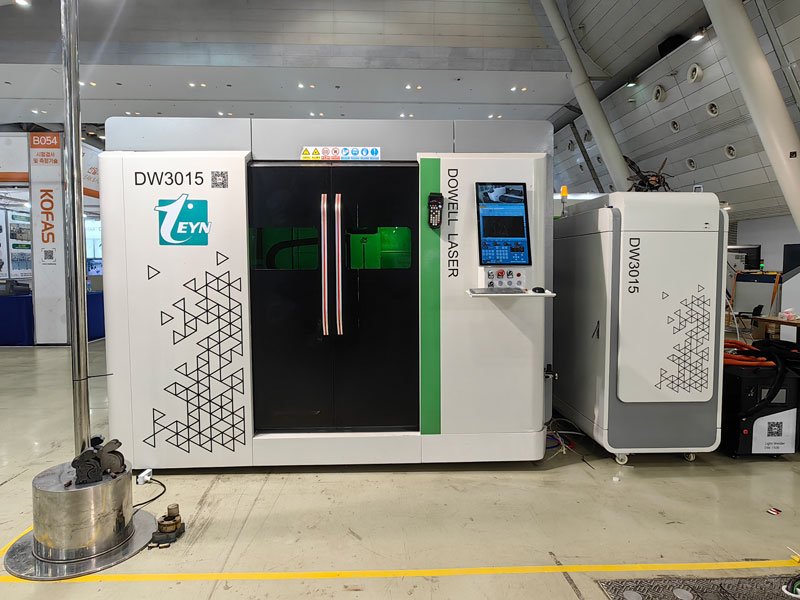

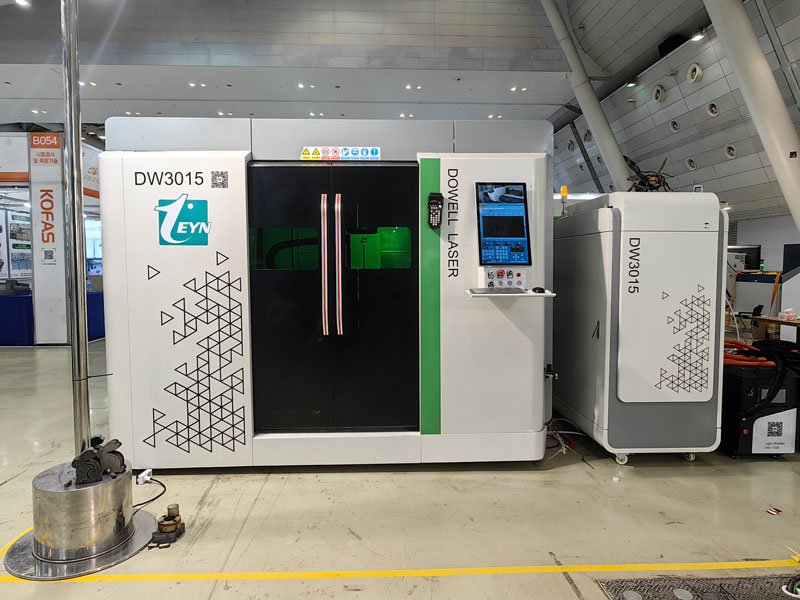

The DOWELL 20000W fiber laser cutting machine is a high-power laser cutting machine specially used to cut thicker metal sheets.

20KW fiber laser cutting machine is often used to cut thicker metal materials such as steel plates, aluminum plates, etc. The higher its power, the higher the cutting speed and efficiency, and the thicker the material can be cut.

The 20000W fiber laser cutting machine has high energy density, realizes ultra-high power output, continuously adjustable laser power, high electro-optical conversion efficiency, and high beam of light quality.

The 20000W laser cutting machine uses oxygen cutting in the carbon steel medium and thick plate cutting process. Its cutting efficiency can be increased by 74.4%-272.9% compared with the traditional process, which is close to the level of air cutting.

High Power and Quality: High electro-optical conversion efficiency, flat-top distribution of spot energy, and high energy density.

Compact Structure: Built-in high-power single-module integration, making the machine smaller and energy-efficient.

Excellent Performance: Processing efficiency can be increased by up to 532%, and annual costs can be saved up to 1.1 million.

Anti-High Reflection: Unique hardware-level anti-high reflection protection technology for processing high reflection materials.

Modular Design: Separate design of photoelectric modules for stable operation and easy maintenance

The appearance of the 20kw laser cutting machine can be customized according to your needs, with a floor cabinet appearance, a fully enclosed large surround, or a single platform appearance.

The maximum cutting thickness of the 20000W laser cutting machine can reach 40mm. This shows that the equipment can easily cut metal materials with a thickness of less than 40mm. For thicknesses exceeding 40mm, the 20000W laser cutting machine can still cut, but the cutting parameters may need to be adjusted according to the specific material characteristics.

Cutting: The machine is designed for high-power cutting of various metal and non-metal materials, such as carbon steel, stainless steel, aluminum alloy, brass, and other steel types.

Welding: It can be used for welding, particularly in applications like laser composite welding and automatic welding.

Drilling: The machine is capable of drilling through materials with high precision and speed.

Cladding: It can be used for cladding, which involves depositing a layer of material onto another surface.

Additive Manufacturing: The machine can be used for additive manufacturing processes, such as 3D printing.

Surface Heat Treatment: It can be used for surface heat treatment, which involves applying heat to specific areas of a material to achieve desired properties

We have been focusing on the production and development of laser equipment for 15 years and have a professional technical team. If you want to know the latest 20kwjiguangqieg laser cutting equipment, please contact us.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!