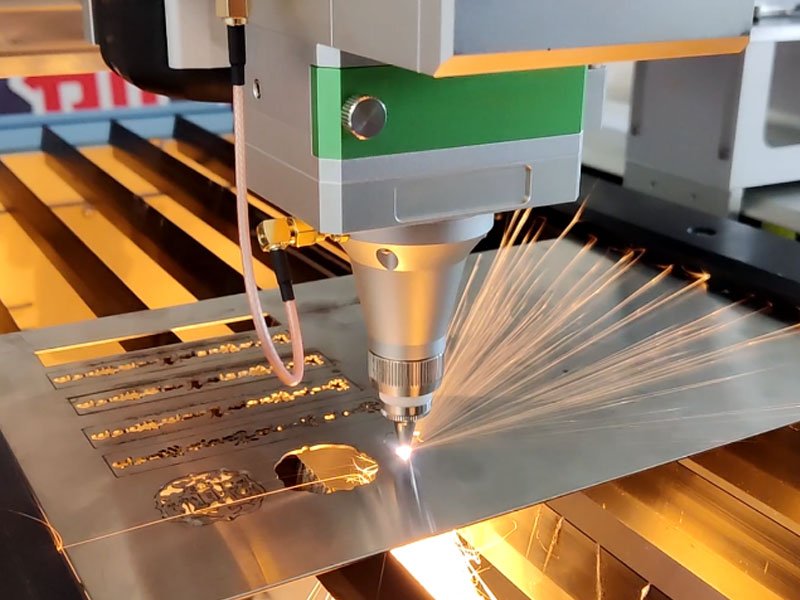

In the use of fiber laser cutting machines, it is very important to choose the right auxiliary gas. Two common gases are oxygen and nitrogen, each of which has different characteristics and applicable scenarios.

This article will introduce the main differences between laser cutting noxygen vs nitroge for novices to help you make a wise choice.

2 Types of Gases for Laser Cutting

Laser cutting is a versatile manufacturing process that can be used to cut a wide variety of materials, including metals, plastics, and wood. There are two main types of gases that can be used for laser cutting: nitrogen and oxygen.

- Nitrogen is a non-reactive gas that is often used for cutting thin materials, such as sheet metal.

- Oxygen is a reactive gas that is often used for cutting thicker materials, such as plate steel.

Advantages of Nitrogen Laser Cutting

- Clean cuts: Nitrogen laser cutting produces clean cuts with minimal heat-affected zone (HAZ). This makes it ideal for cutting materials that are sensitive to heat.

- Versatility: Nitrogen laser cutting can be used to cut a wide variety of materials, including metals, plastics, and wood.

- Low cost: Nitrogen is a relatively inexpensive gas, which makes it a good choice for budget-conscious applications.

Advantages of Oxygen Laser Cutting

- Faster cutting speeds: Oxygen laser cutting is faster than nitrogen laser cutting. This makes it a good choice for applications where speed is important.

- Thicker material cutting: Oxygen laser cutting can be used to cut thicker materials than nitrogen laser cutting. This makes it a good choice for applications where thicker materials are required.

Fiber Laser Cutting Oxygen Vs Nitrogen

- Cutting effect

Oxygen: When using oxygen as an auxiliary gas, laser cutting speed is faster, especially suitable for cutting carbon steel and low alloy steel. Oxygen reacts with metal to generate additional heat, which improves cutting efficiency. However, this reaction may cause oxidation of the cut edge, affecting subsequent processing.

Nitrogen: Nitrogen is suitable for cutting materials such as stainless steel and aluminum alloy. It does not react with metal, so you can get a cleaner cut edge and reduce oxidation. This is especially important for applications that require high-quality surface treatment.

- Cutting speed

When using oxygen, the cutting speed is usually faster because it can provide additional heat to help melt the metal quickly.

When using nitrogen, the cutting speed may be slightly slower, but the overall quality of the final product is better due to the higher edge quality.

- Cost considerations

Oxygen is generally cheaper than nitrogen, so using oxygen in large-scale production can reduce costs.

However, in some cases。

How to Choose the Right Laser Cutting Nitrogen Vs Oxygen

- Material type

If you mainly cut carbon steel or other materials that are easy to oxidize, choosing oxygen will be more conducive to improving production efficiency.

For stainless steel or aluminum alloys that need to keep the surface smooth and free of oxide layer, nitrogen is recommended.

- Cutting thickness

For thinner materials (such as 2-5mm), oxygen can significantly increase the cutting speed.

For thicker materials (such as more than 20mm), nitrogen may be a better choice to ensure edge quality.

- Subsequent processing needs

If your product requires subsequent processing such as welding or painting, using nitrogen can reduce problems in surface treatment.

If subsequent processing is not important, using oxygen can improve production efficiency.

Conclusion

Nitrogen and oxygen are both good gases for laser cutting. The best gas for you will depend on the type of material you are cutting, the thickness of the material, and your budget.

If you are a beginner who is interested in fiber laser cutting machines, I recommend talking to a laser cutting expert. They can help you choose the right gas for your application.