China Heavy Duty Metal Pipe Laser Cutting Machine Suppliers

DOWELL 12m side mounted laser tube cutting machine can easily handle 12-meter long heavy-duty pipes, and can cut, punch and other precise cutting on the pipes.

DOWELL 12m side mounted laser tube cutting machine can easily handle 12-meter long heavy-duty pipes, and can cut, punch and other precise cutting on the pipes.

Dowell heavy-duty laser pipe cutting machine types include semi-automatic side-mounted laser pipe cutting machine and three-chuck side-mounted laser pipe cutting machine. Different chucks and 9m 12m 24m bed can be customized according to customer needs.

A heavy-duty laser tube cutting machine is a powerful industrial machine used for cutting thick metal tubes and pipes with high precision. They are ideal for heavy-duty applications in industries like aerospace, shipbuilding, construction, and oil and gas.

Semi-automatic loading, saving time, can achieve fast cutting, and the front chuck can realize follow-up cutting

The pneumatic chuck has a large and adjustable automatic clamping force, no fear of loosening and slipping when cutting heavy pipes, and no deformation when clamping light and thin pipes

It can cut heavy I-beam, special-shaped pipe, angle steel, channel steel, round pipe and square pipe

Cutting material stainless steel, broken steel, aluminum, copper, iron, etc.

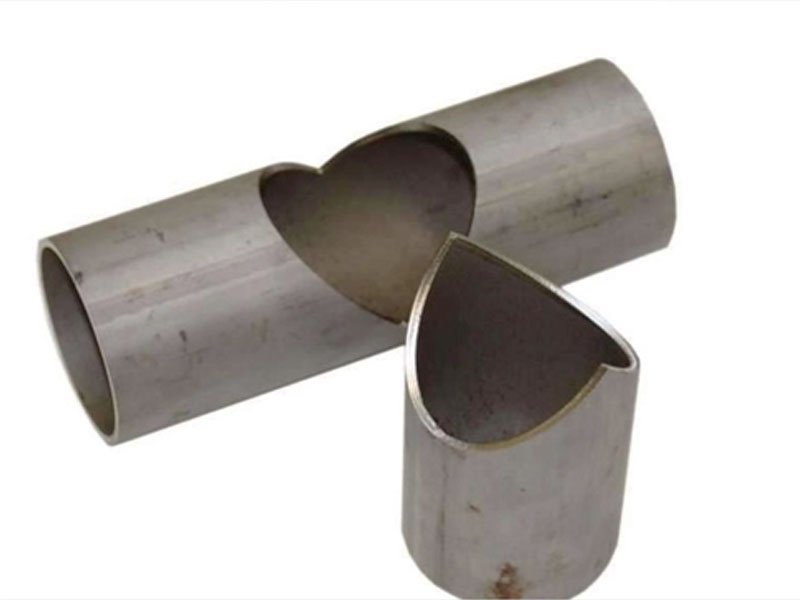

It can cut, punch, cut arcs, slot and other processing on metal pipes. The CNC cutting system software can cut any graphics

Suitable for heavy pipe cutting industries, such as shipbuilding, engineering machinery, power towers, bridge construction, tunnel traffic

Steel formwork is the most widely used bridge formwork, most of which are used in: highway bridges, viaducts, overpasses, etc., to pour concrete into beautiful equipment. The quality requirements are relatively high, and certain hardness, strength, precision, etc. must be achieved, so that the bridge can be used safely.

12000W-30000W laser cutting equipment, more suitable for efficient cutting of the entire steel plate and connecting accessories

In the manufacturing process of ships and ferries, new technologies such as laser cutting, cleaning and welding have replaced traditional cutting methods. Marine steel plates require high precision, low noise, good cutting quality, and no secondary processing is required. Using laser cutting technology, not only does not need to use abrasive tools, but also ensures the cutting quality. This provides a guarantee for the quality of raw materials in the shipbuilding industry, thereby reducing the workload of assembly, assembly cycle, waste of materials and labor costs.

Power towers use relatively thick metal pipes, so the requirements for cutting are higher. DOWELL large-format high-power laser cut machine medium can solve this processing problem. The 12000W-30000W laser cutting equipment can meet the needs of large plate cutting, Medium and thick plate cutting, ±45° bevel cutting and other needs, high cutting efficiency!

Pipe laser cutting equipment is often used in the production of various pipes and pipelines in rail transit facilities, lighting in tunnels, ventilation pipes, drainage pipes, etc.

Laser cutting technology is efficient and precise, which can better guarantee the processing quality. strong penetrating power,

Not limited by the hardness and thickness of the pipe, it can cut steel, aluminum, copper and other metal materials, so it can meet the diverse needs of rail transit facilities.

Consult DOWELL tube laser cutting machine factory to obtain the latest quotation and catalog of laser pipe cutting machine

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.