One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

How to choose the best laser cleaning machine based on the quality of the laser cleaning equipment and the type of clean laser machine. We hope you enjoyed this guide on clean laser machines.

It would be perfect if you had a cleaning solution that is both secure and efficient, whether water has rusted your aircraft’s bulkhead or dangerous paint is starting to peel off your machinery. Laser ablation uses cleaning to remove mold-releasing agents, oil, rust, paint, and more. But how do you pick the best laser rust removal machine for your needs? Are there different kinds, and what information should you have before buying an acrylic cutter machine?

If you want to buy the best laser rust removal machine, you need to know the material of the substrate to be cleaned:

If you want to know the best laser cleaning machine manufacturers in 2023, you can consult us for the latest price list.

A laser cleaner machine ( laser cleaning systems, laser rust removal machine is a laser ablation machine that removes surface material by heating and irradiating an object’s surface with a CW (Continuous Wave) or pulsed laser to cause it to evaporate or sublime.

Other names for the metal laser parts cleaning include:

Rust cleaning laser.

Laser rust cleaning device.

Laser paint removal device.

Laser paint stripping device.

Laser coating removal device.

Laser rust removal device.

Laser oxide removal device.

Laser dirt cleaning device.

Laser oil cleaning device.

Laser descaler device.

The two popular fiber laser cleaners are continuous lazer cleaning machinery and pulsed laser cleaner.

A pulsed laser CNC machine is outfitted with a Galvo clean head and a pulse laser source. Use a pulsed laser cleaning system if you have expensive products that need to be cleaned without damaging the foundation components.For laser degreasing, paint disposal, laser zinc removing it, laser film removal, and laser coating, laser cleaners were developed. Most commonly, a laser cleaning equipment is used to remove plating, coatings, paint, rust, and rubber mould residue from metal surfaces.

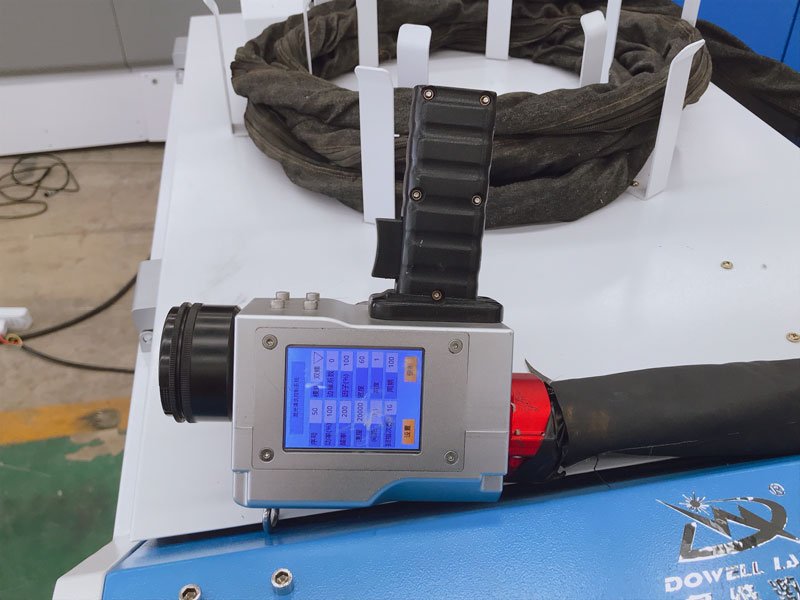

The Continuous fiber laser metal cleaner employs a portable clean head and a continuous laser source. The benefit of the Continuous fiber hand held laser cleaner is its great performance-cost ratio. The cost-effective Continuous fiber precision laser cleaning can satisfy the need to remove thin layers of paint or rust from stainless steel, mild steel, or iron. A Continuous fiber portable laser cleaning machine supports 1000W, 1500W, and 2000W.

Realizing handheld laser cleaning, the equipment is easy to install, control and automate.

It is simple to operate. Just turn on the power and turn on the device to perform cleaning without chemical reagents, media, dust, and water. It can automatically focus, clean on curved surfaces, and has the advantages of high cleaning surface cleanliness. It can remove resin and oil stains on the surface of objects. , stains, dirt, rust, coatings, plating, paint.

Laser rust removal machines can be used in many industries such as marine, bridges, petrochemicals, railways, automobiles, construction, heavy machinery and steel structures, providing efficient and environmentally friendly rust removal solutions for these industries.

The price of laser cleaning machines on the market is related to the thickness of the clear plate and the power. It is generally around US$5,000-10,000. If you want to get the cheapest laser cleaning machine price, you can consult the relevant

We divided the following information into two major areas based on process and CNC laser engraver parameters. Why is it vital to take these things into account? Because these elements affect how a laser cleaner machine is often specified. You will receive the best product solution and anticipated performance from an appropriate rust cleaning laser machine.

According to control theory, a process parameter is the measured value of a process component. Typically, the operator monitors or adjusts these process parameters depending on the situation. Therefore, using the following criteria to select the best lazer cleaning machines are useful.

Numerous pollutants are created during laser cleaning. In this instance, vaporization is necessary to turn the impurities into dust or fumes to meet laser cleaning standards. These contaminants must be removed from the working area. However, ensuring this feature of laser cleaner keeps workers safe and the workspace organized.

Check the position of the fume extraction nozzle first. After that, examine the PLC automated communications’ safety controls. Finally, examine the filter and extraction devices depending on the kind of dust or fumes created.

Two common laser frequencies can be used in laser machines: continuous and pulsed. It indicates that a constant laser frequency produces excellent quality and power laser beams. For laser cutting and welding, the continuous laser is renowned. However, high energy consumption is required by this kind of laser machine.

On the other hand, a pulsed hobby cnc laser cutter of DOWELL LASER generates irregular bursts of laser frequency—this laser’s famed cleaning, marking, or etching capabilities. Therefore, checking the laser power of the machine you choose is crucial.

Some people could need clarification on the difference between scanning and cleaning speeds. A scanning speed is the rate of operation at which a Galvo scanner produces a laser spot with a particular width. In this instance, the CNC laser cleaning machine speed is parallel to this laser spot. For instance, using various lasers, DOWELL LASER CNC offers cleaning speeds ranging from 0.5 m2/h to 15 m2/h.

Cleaning intervals are yet another crucial aspect that you should take into account. The number of operations necessary to obtain the specified cleaning qualities is called the cleaning times. In addition, the change in surface roughness varies with the speed of the laser cleaning. Therefore, you should do many laser cleaning procedures to achieve the ideal state.

Every DOWELL LASER laser metal cleaner has always been designed with safety as the top priority. Typically, a class-1 safety enclosure is needed for a laser machine. It secures the reliability of the work. In addition, every laser machine manufacturer must adhere to international safety standards. Therefore, you won’t require any PPEs if the laser machine has installed a class-1 laser safety enclosure. However, you should ensure the safety enclosure class is met in the case of a handheld laser cleaner. If the level is 4, then you might need more PPE.

We’ve studied the principles of a few process parameters that could aid your decision-making. This part will discuss a few visible machine parameters of various types. Consider the following factors to ensure your company operates at its highest production level.

Yet another essential component of laser cleaning is the overlap ratio. It is observed that cleaning speed, pulse frequency, and power are affected by overlap ratio and energy density. Therefore, these two parameters affect the combined value of the projected metal part’s surface roughness.

Why is this important to take into account when selecting a laser machine? Because it will inform you of the machine’s overall productivity. The lab test records included with the portable laser engraver allow you to verify these characteristics.

Every repair shop or recycling facility should have a laser cleaning equipment. Selecting a laser cleaning device appropriate for your application might be challenging. However, it would be best only to comprehend the laser cleaner’s operation and operating parameters. If you can access all the information above, making the appropriate choice will be simple.

The leading global producer of laser cleaning system is DOWELL LASER. It is well known for offering a variety of CNC and mini laser cutters. Call us if you have queries. Experts at DOWELL LASER are available to respond to your queries at any time.

In the industrial market for laser cleaners for sale, the most common one is the 1000w rust cleaning laser, which has a relatively high demand. There are also 1500w, 2000w, 3000w, and some more popular brands. P laser cleaning systems are currently one of the most popular equipment on the market. First, the type of ir laser cleaner is also very popular among customers.

If you have a limited budget for purchasing laser that removes rust in the early stage, you can consider laser rust removal service near me rental, which can save your money, but you should also consider that the used laser rust removal tool will have large and small The fault, this is relatively troublesome to use.

Laser cleaning services can not only be used for metal workpieces, but also for non-metallic workpieces. Attachments on non-metallic workpieces such as ceramics, wood, glass, paper shells, bricks, and walls are all acceptable.

2000w portable laser cleaner equipment depends on the brand, the configuration used, and the cleaning gun. The market cost is generally $5000-$10000. For specific prices, please consult laser cleaning companies.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.