After purchasing the metal laser cutting machine, the supplier has trained the technicians, but how to operate the cnc laser cutting machine is still unclear to many people. Now I will give you the specific operation steps to facilitate your good use of laser cutting equipment and better improve production capacity.

Step by step guide to how use a laser cutting machine

- Preparation: Make sure the power supply and cooling system of the laser cutting machine are working properly, check whether the cutting head and optical fiber of the cutting machine are clean, and prepare the materials that need to be cut.

- Set parameters: Set appropriate cutting parameters according to the type and thickness of material to be cut. These parameters include laser power, cutting speed, gas flow, etc.

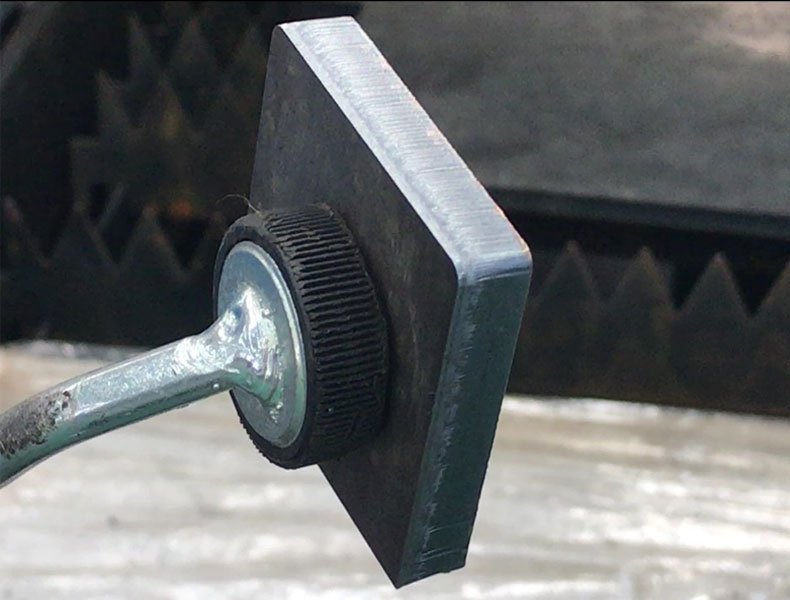

- Position the material: Place the material to be cut on the cutting table and fix it using clamps or magnetic suction to ensure the accurate position of the material.

- Adjust the focal length: Adjust the focal length of the cutting head so that the laser beam can accurately focus on the material surface. This can usually be achieved by moving the cutting head or adjusting the lens.

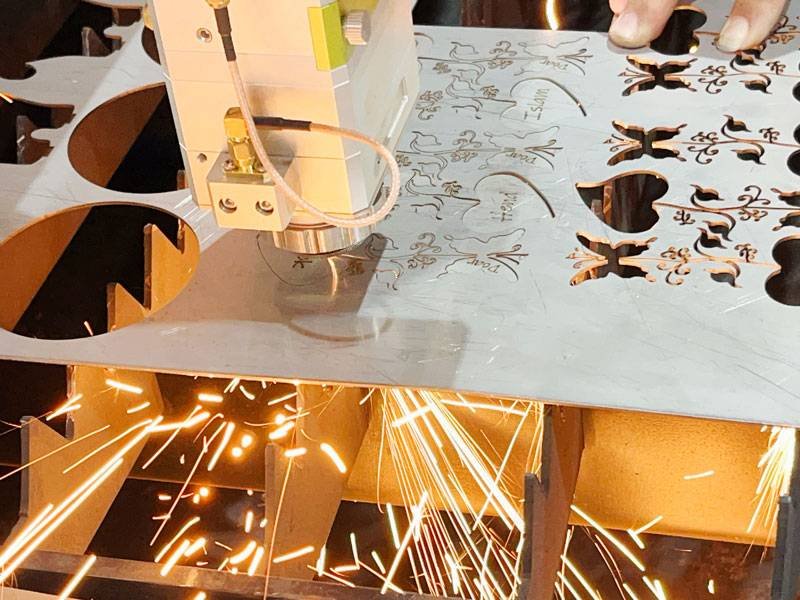

- Start cutting: Press the start button and the laser cutting machine starts working. The laser beam is emitted from the cutting head, focused by the lens, and irradiated on the surface of the material for cutting.

- Monitor the cutting process: During the cutting process, you can monitor the cutting process by observing the positional relationship between the cutting head and the material, as well as the quality of the cutting lines. If necessary, the cutting parameters or focal length can be adjusted to optimize the cutting effect.

- Complete cutting: When the cutting is completed, stop the laser cutting machine. Pay attention to safety and wait for the cutting head to cool before proceeding to the next step.

- Cleaning work: Clean up the waste and debris generated by cutting, clean the cutting head and optical fiber, and ensure the normal use and maintenance of the equipment.

It should be noted that when operating a laser cutting machine, you must strictly abide by relevant safety operating procedures, wear personal protective equipment, and avoid direct exposure of the laser beam to your eyes or skin to avoid causing damage.

Big guys know that in daily production, as long as the use of machinery and equipment, in the long working operation will appear in the loss of equipment, aging phenomenon, over time will be frequent failures, fiber laser cutting machine as high-tech products are no exception.

Fiber laser cutting machine components in the laser is easy to old loss of components, resulting in laser cutting machine power weakening roughly two reasons, so in the daily use of either the operator or laser cutting custom manufacturers should pay attention.

How to slow down the aging of metal laser cutting machine?

- First of all, the need for regular inspection and maintenance of the external optical path of the laser generator. Laser cutting machine in continuous use for a period of time, the power will decline. When the power drops and thus affects production, the laser and the external light path should be maintained. When the maintenance is completed, the cutting capacity will be restored to the factory level.

- Secondly, the environment and conditions of the production site have a great impact on the power of the laser cutting machine. Such as the quality of compressed air, the production site dust, and so on, some manufacturers even put the painting operation near the fiber laser cutting machine, which will lead to the laser cutting machine cutting quality and cutting capacity of the decline.

How should the laser cutting equipment ask to remedy it?

- Regular cleaning of the laser cutting machine dust and debris, try to do every five days to clean up once!

- Once a week to check the steel belt, whether to pull tight. Avoid malfunctioning accidental injury to the operator.

- Often clean each guide, clean up dust and other debris, so that the laser cutting machine normal operation.

- Often wipe the rack, regularly add appropriate lubricant, lubrication and no debris. Reduce rack wear.