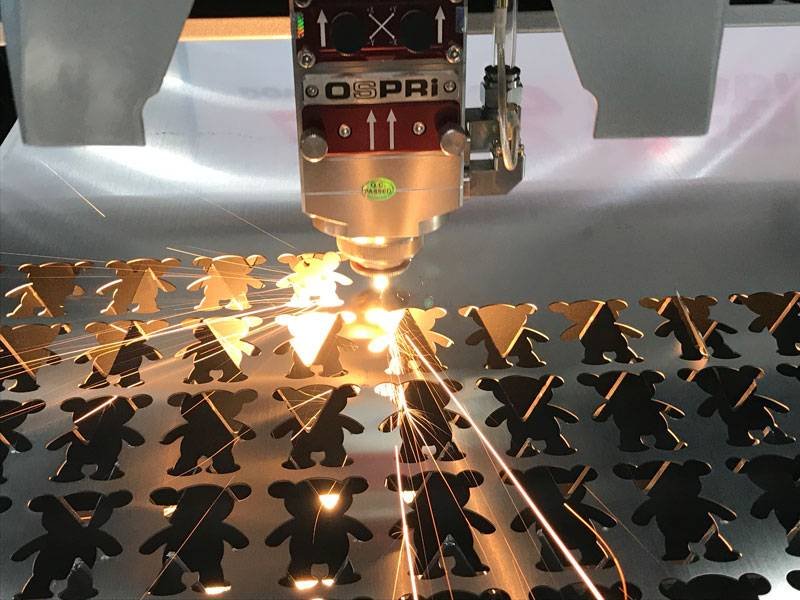

Are you looking for information about laser cutting machine for sheet metal, and want to know the guide about the equipment, then this article hopes to be helpful to you.

We’ll dive into the details of metal laser cutting machines, how they work, and their various applications. Whether you are a manufacturing veteran or just starting out, this section will give you a comprehensive overview of these laser cutting equipment.

We are a professional metal laser cut machine manufacturer in China. We have been focusing on the production and development of laser equipment for 13 years, and can provide you with a one-stop metal sheet cutting solution.

Laser cutting machines currently on the market for cutting metal:

| Type of Machine | Power Range | Size Options |

|---|---|---|

| Precision Laser Cutting Machine | 1000w-3000w | 1313, 1325, 1515 |

| Small Power Laser Cutting Machine | 1000w-3000w | 3015, 4015, 6015 |

| Medium Power Laser Cutting Machine | 6000w-10000w | 1313, 1325, 1515 |

| High Power Laser Cutting Machine | 12kw-30kw | 6020, 6025, 8025, 12025 |

Dowell sheet metal laser cutting machine suppliers can be customized according to the laser cutting design you provide.

Whether a cheap sheet metal laser cutting machine is worth buying depends on a variety of factors. Here are some things to consider:

Your Budget: If you’re on a tight budget, a cheap machine might be the only option. However, keep in mind that low-cost options may not offer the same level of functionality or durability as more expensive ones.

Your Needs: The complexity and volume of your projects will determine the type of machine you need. If you’re working on small, simple projects or if you’re just starting out, a cheap machine might suffice. If you’re running a business that requires high output or complex designs, a more advanced (and probably more expensive) machine would be more appropriate.

Quality and Durability: Cheaper machines might not be as durable or reliable as their more expensive counterparts. They may also lack certain features, such as advanced software, higher cutting speed, or a larger cutting area.

Maintenance and Repair: Lower-cost machines might require more maintenance and could be more difficult or costly to repair, which might offset any initial savings.

Customer Support: More expensive machines often come with better customer support, which can be critical when you’re facing issues or need help with the machine.

Resale Value: More expensive machines might have a higher resale value, which could be a factor if you plan to upgrade in the future.

Many metal laser cutting machine beginners may encounter common problems such as cutting quality, machine maintenance, and operating efficiency when using it.

The following are some practical solutions for cnc laser cutting machine sheet metal. By incorporating expert advice and innovative industry standards, we will help you improve the operation of your metal laser cutting machine and optimize your production process.

Many operators face inconsistent cut quality, which can lead to wasted material and increased production time.

Solution: Calibration is key. Regular machine calibration ensures precise laser focus for improved cut quality. Using the right cutting gas for different metals can also greatly affect the quality of the cut.

Regular maintenance and replacement of worn parts is costly and time consuming, affecting overall productivity.

Solution: Implement a rigorous preventative maintenance program to minimize downtime and reduce unplanned breakdowns. Investing in high-quality consumables and parts, while initially more expensive, will often reduce long-term costs by extending the life and reliability of your machine.

Operators often struggle to maximize the operating efficiency of their machines, which impacts overall throughput and profitability.

Solution: The best way to train your operators to use your machine can greatly improve operational efficiency. In addition, utilizing software that provides nesting capabilities can optimize the layout of parts on the material, reducing waste and increasing productivity.

With the rapid development of the industrial market, there are many brands of sheet metal laser cutting machine companies. It is relatively difficult for beginners to purchase. Here are some suggestions for you:

Choosing the right sheet metal laser cutting machine company can be a complicated task due to the variety of options available in the market. Here are some key factors to consider when making your choice:

Search on Google, Alibaba or Amazon: metal laser cutting machine, find the corresponding website of the company, and look at the company’s production experience.

Looking for high-quality sheet metal laser cutting machine manufacturers, the strength of the company, and the level of R&D personnel are also critical.

Supplier reliability of sheet metal laser cutter core components, governance and safety.

It is very important whether the sheet metal laser cutter factory can provide training on laser equipment operation, technical problems, and timely feedback.

The price of the sheet metal laser cutter should be within the budget that you can control. If you have a limited budget in the early stage, you can consider purchasing a used laser cutting machine, but be careful that the maintenance cost will be higher.

Look for companies with positive customer reviews and testimonials. This can provide valuable insight into the quality of a company’s products and services.

Comprehensive warranty can provide you with a good guarantee. Make sure you understand the terms of the warranty, including what it covers and how long it lasts.

According to your laser cutting machine design requirements, check whether metal laser cutting machine supplier provides customization options for their machines.

Keeping these points in mind, you can be sure to choose a sheet metal laser cutting machine company that offers reliable, high-quality machines that meet your specific needs.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.