For many laser cutting beginners, they want to convert their design ideas into recognizable software for metal laser cutting machines. For example, 2D vector graphics files in dxf, .dwg, .ai or .eps format require the use of software for laser cutting.

Master the world of laser cutting! This in-depth guide explores everything you need to know about laser cutting software, from free options for beginners to advanced features for seasoned creators. Discover top software like LightBurn, RDWorks, and CorelDRAW, plus tips for choosing the right one for your needs.

In this article, we will introduce some of the best design software for laser cutting and how to choose laser cutting parts software.

What is laser cutting software ?

Laser cutting software refers to the software used to control the laser cutting machine for cutting operations. It can convert design drawings into instructions that the laser cutting machine can recognize, thereby achieving exquisite cutting effects.

How does laser cutting software work?

- Import design drawings: Import design drawings into the software. Common formats include DXF, DWG, SVG, etc.

- Set cutting parameters: Set cutting speed, power, and other parameters according to material type, thickness, and other parameters.

- Generate cutting path: The laser cutting program generates the motion path of the CNC laser cutting machine based on the design drawings and cutting parameters.

- Send instructions: Send the cutting path to the CNC laser cutter to start the cutting operation.

What software is used for laser cutting

Types of Laser Cutter Software :Raster vs vector software

According to different working principles, laser cutting program can be divided into raster software and vector software.

Raster vs. Vector Laser Cutting Software:

| Feature | Raster Software | Vector Software |

|---|---|---|

| How it works | Converts the image into a pixel matrix and cuts it one by one. | Converts images into vector curves and cuts according to the curves. |

| Advantages | Easy to operate | High cutting accuracy |

| Disadvantages | Lower cutting accuracy | Relatively complicated operation |

| Suitable for | Beginners | Users who require high cutting accuracy |

| Applicable scenarios | Simple graphic cutting, photo engraving | Complex graphic cutting, text cutting, badge cutting |

| Common software | LaserWeb | Inkscape, CorelDRAW |

Commonly used materials

Laser cutting program can be applied to cutting the following materials:

- Metal: carbon steel, stainless steel, aluminum alloy, copper, brass, etc.

- Non-metal: wood, acrylic, plastic, rubber, ceramic, glass, etc.

- Fabric: cotton, linen, silk, polyester, nylon, etc.

Advantages of laser cutting machine software programs:

- High cutting accuracy: Laser cutting is a non-contact processing method that does not cause mechanical stress to the material, so the cutting accuracy is high and the edges are smooth.

- Fast cutting speed: Laser cutting has high energy density, fast cutting speed, and high efficiency.

- Wide range of cutting materials: Laser cutting can be applied to various metal and non-metal materials, such as wood, acrylic, metal, ceramics, etc.

- Simple operation: The laser cutting programs have a friendly operation interface and are easy to learn and use.

Best Design and Control Laser Cutting Software programs

Free laser cutting design software

For beginners or those on a budget, there are free laser cutting software options. Here are some common free software:

| Feature | LaserGRBL | Inkscape |

|---|---|---|

| Type | Open Source | Open Source |

| Platform | Windows Only | Windows, Mac, Linux |

| Interface | Beginner-friendly | More complex |

| Features | Basic design tools, laser control | Powerful vector editing, laser cutting support |

| Strengths | Free open source laser engraving and cutting software Easy to learn, ideal for beginners | Versatile, suitable for complex designs |

| Weaknesses | Limited design capabilities | Steeper learning curve |

| Best for | Simple projects, getting started with laser cutting | Detailed designs, advanced projects |

Best paid design software for laser cutting

Paid software is usually more powerful and provides better technical support.

- LightBurn is a versatile and user-friendly software suitable for both beginners and experienced users. It offers a wide range of features, making it a great all-in-one solution for laser cutting and engrave.

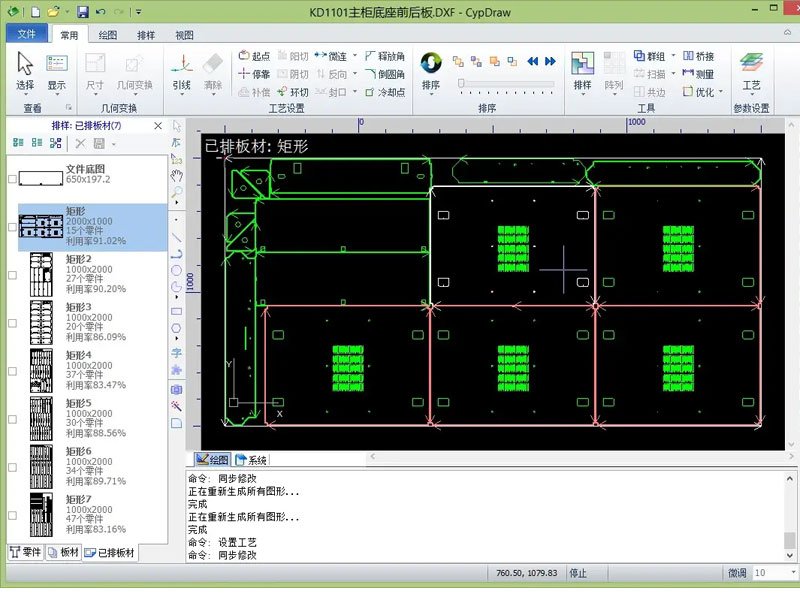

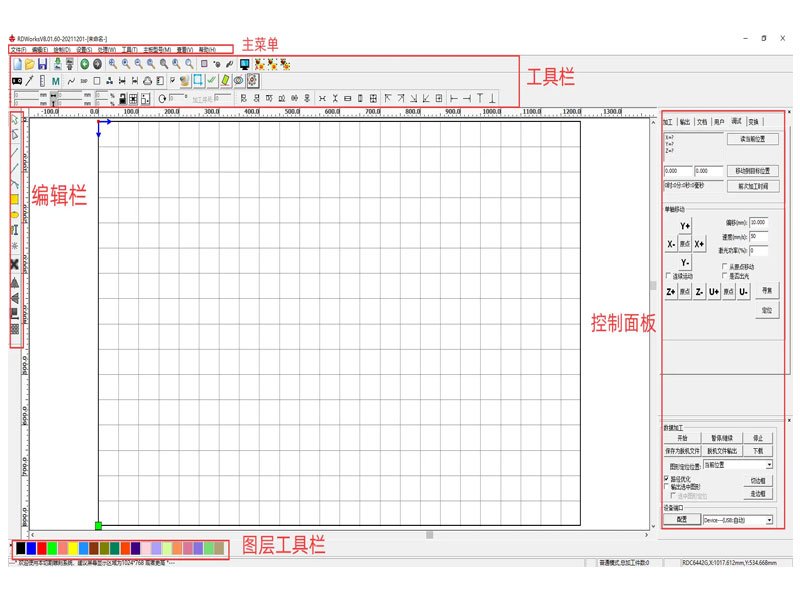

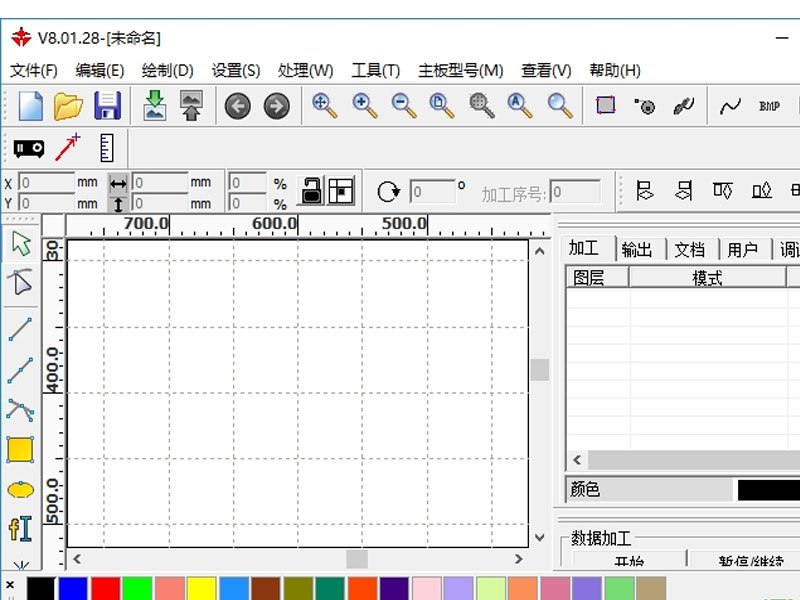

- RDWorks is a powerful software designed specifically for Reda controllers. It offers powerful CAM tools and excellent compatibility with Ruida systems. A professional laser engraving and cutting program that is compatible with most laser cutting machines. RDWorks provides a wealth of editing and layout tools, including custom tool libraries, power-off recovery, image import, trimming, splicing, and repositioning functions. In addition, RDWorks also supports vector and raster image import, DXF and DWG file formats, standard G-code output and other functions.

- CorelDRAW is a professional vector design software with a laser cutting plugin. It is ideal for professional designers who need advanced design capabilities.

Here are some common paid software:

| Feature | LightBurn | RDWorks | CorelDRAW |

|---|---|---|---|

| Platform | Windows, Mac, Linux | Windows | Windows, Mac |

| Price | $99 (Single license), $499 (Lifetime license) | $299 (Standard Edition), $899 (Advanced Edition) | $239/year (Subscription), $699 (Perpetual license) |

| Interface | User-friendly | Intuitive | Professional |

| Features | Extensive design tools, laser control, simulation, camera integration | Optimized for Ruida controllers, powerful nesting, macros | Advanced vector design, laser cutting plugin, 3D design capabilities |

| Strengths | All-in-one solution, ideal for beginners and experienced users | Robust CAM tools, perfect for Ruida users | Industry-standard design software, suitable for professional designers |

| Weaknesses | Can be overwhelming for beginners | Limited to Ruida controllers | High learning curve, expensive |

| Best for | Hobbyists, small businesses, makerspaces | Businesses with Ruida controllers, professional users | Professional designers, large-scale projects |

The choice of laser control software depends on your specific needs, budget, and skill level. Consider the features, strengths, and weaknesses of each software to find the best one for you.

Choosing the Right laser cutting design software

- Budget: Free software can meet basic needs, and paid software has more powerful features.

- Skill level: Beginners can choose software with simple operations, while advanced users can choose software with powerful functions.

- Compatibility: Make sure the software is compatible with your laser cutting machine.

- Functional requirements: Select the corresponding functions according to your needs.

Common Features of software for laser cutting

- Import and export files: Supports common CAD file formats such as DXF, DWG, SVG, etc.

- Design and editing tools: Provides design tools such as shapes, text, images, etc., as well as editing functions.

- Laser control and settings: You can set cutting speed, power, focal length and other parameters.

- Simulation and preview: You can simulate the cutting process and preview the cutting effect.

- Safety function: Provide safety settings, such as origin setting, interlocking, emergency stop, etc. .

Laser engrave software vs laser cut software program

Laser cutting software is used to cut materials into specific shapes.

Laser engrave software is used to engrave patterns or text on the surface of materials.

Laser Cutting vs. Laser Engraving Software

| Feature | Laser Cutting Software | Laser Engraving Software |

|---|---|---|

| Typical Material Thickness | Thicker (wood, metal, plastic) | Thinner (paper, plastic, wood) |

| Power Requirement | Higher | Lower |

| Precision Requirement | More precise control | Less precise control |

| Primary Function | Cut materials into specific shapes | Engrave designs or text onto surfaces |

| Examples | Cutting wood signs, metal parts, plastic stencils | Engraving logos on wood, labels on plastic, designs on paper |

FAQ

Is laser cutting software expensive?

Laser cutting software ranges from free to hundreds of dollars. Free options have basic features, while paid software offers more power and support. Consider your needs and budget when choosing.

How to choose the right laser cutting design software ?

Focus on your budget, skill level, and desired features (e.g., design, laser controls). Ensure compatibility with your laser cutter. Popular options include free (LaserGRBL, Inkscape) and paid (LightBurn, RDWorks, CorelDRAW) software.

What are the common laser cut programs ?

Both free and paid options exist. Popular choices include LaserGRBL and Inkscape (free) and LightBurn, RDWorks, and CorelDRAW (paid).

What functions does laser cut software have ?

Import/export files (DXF, DWG, SVG), design & editing tools, laser controls (speed, power), simulation/preview, and safety features are typical functionalities.

How to learn to use design software for laser cutting ?

Many resources exist! Leverage software tutorials, free video tutorials, training courses (offered by some companies), and online laser cutting communities for guidance.