In today’s fast-paced manufacturing landscape, small businesses face the challenge of staying competitive while maintaining cost efficiency and high product quality. One technology that has become increasingly accessible and transformative for small-scale manufacturers is laser welding machines. These machines bring precision, durability, and cost-effectiveness to the forefront, making them a valuable investment for small businesses.

In this blog, we’ll explore the benefits of laser welding machines, why they’re ideal for small businesses, and how this technology can take your operations to the next level.

What Are Laser Welding Machines?

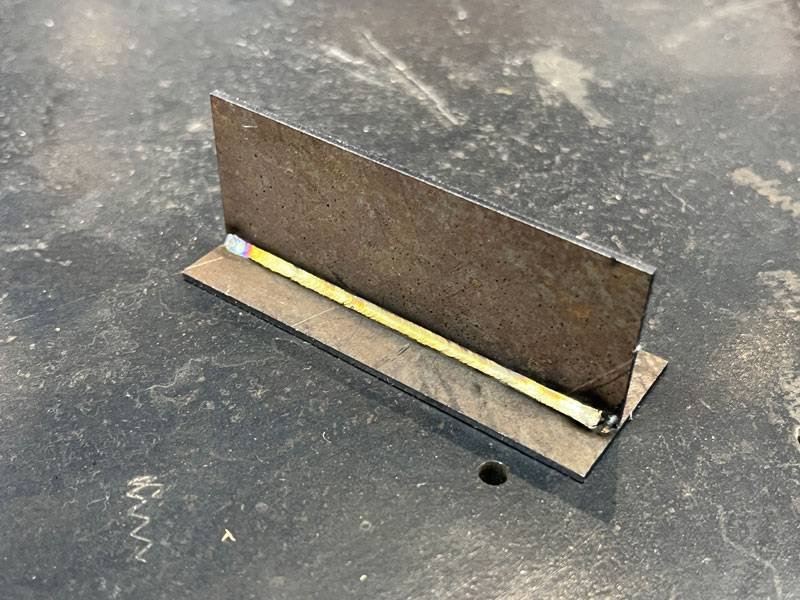

Laser welding machines use a highly focused laser beam to join materials with incredible precision. Unlike traditional welding methods, laser welding minimizes heat distortion, reduces material waste, and creates strong, seamless joints. These machines are versatile, capable of welding metals, alloys, and even plastics, making them suitable for a wide range of industries.

Why Should Small Businesses Invest in Laser Welding Machines?

For small businesses, purchasing a laser welding machine may seem like a significant investment. However, the long-term benefits far outweigh the initial cost. Here’s why:

1. Precision on a Budget

Small businesses often work with intricate designs and tight tolerances, especially in industries like electronics, jewelry, and medical devices. Laser welding machines deliver unmatched precision, ensuring high-quality results without the need for expensive rework or material waste.

2. Efficiency and Speed

Time is money, especially for small businesses with tight production schedules. Laser welding machines are highly efficient and can complete welding tasks much faster than traditional methods. This means you can take on more projects and meet deadlines without compromising on quality.

3. Cost-Effectiveness

Although the initial investment may seem steep, laser welding machines save money in the long run by reducing material waste, energy consumption, and labor costs. With fewer errors and less need for manual intervention, your business can achieve higher profitability.

4. Versatility Across Applications

Laser welding machines are incredibly versatile. Whether you’re working on stainless steel, aluminum, titanium, or even delicate materials like gold, these machines can handle it all. This flexibility allows small businesses to tap into new markets and offer a wider range of products.

5. Minimal Training Required

Modern laser welding machines are designed with user-friendly interfaces, making them accessible even to operators with minimal training. This reduces the learning curve and allows your team to quickly adapt and start producing high-quality welds.

Industries That Benefit from Laser Welding Machines

- Jewelry and Watchmaking: Create intricate, delicate designs with precise welds that maintain the aesthetic and structural integrity of fine pieces.

- Medical Devices: Manufacture biocompatible components with clean, strong welds suitable for surgical tools and implants.

- Electronics: Weld microcomponents and delicate circuits with minimal heat distortion.

- Automotive: Produce small, high-performance parts like sensors, brackets, and custom components.

- Aerospace: Achieve lightweight, durable welds for small-scale aerospace components.

How to Choose the Right Laser Welding Machine for Your Small Business

1. Budget

Look for a machine that fits your budget while providing all the necessary features for your application. Desktop and portable laser welding machines are often more affordable and ideal for small businesses.

2. Material Compatibility

Ensure the machine can handle the types of materials you work with, whether it’s metals, alloys, or plastics.

3. Power and Speed

Choose a machine with sufficient power to handle your workload. Higher power machines can weld thicker materials and complete tasks faster.

4. Ease of Use

Opt for a machine with an intuitive interface and easy setup to minimize downtime and training costs.

5. After-Sales Support

Partner with a manufacturer or supplier that offers reliable customer support, training, and maintenance services.

Top Benefits of Using Laser Welding Machines in Small Businesses

1. Improved Product Quality

With laser welding, you can produce parts with seamless, durable welds that meet the high standards of your customers.

2. Competitive Edge

Access to advanced welding technology enables small businesses to compete with larger manufacturers by offering precision and reliability.

3. Scalability

As your business grows, laser welding machines can easily scale with your operations, handling larger volumes without compromising on quality.

4. Reduced Carbon Footprint

Laser welding is an eco-friendly technology that consumes less energy and produces minimal waste, helping your business meet sustainability goals.

Conclusion:

Investing in a laser welding machine is no longer reserved for large corporations. With advancements in technology, these machines are now more affordable, efficient, and accessible for small businesses. Whether you’re in jewelry, electronics, automotive, or medical manufacturing, laser welding can elevate your operations, improve product quality, and boost your bottom line.

If you’re ready to transform your manufacturing process, start exploring the wide range of laser welding machines available today. With the right machine, your small business can achieve big results!