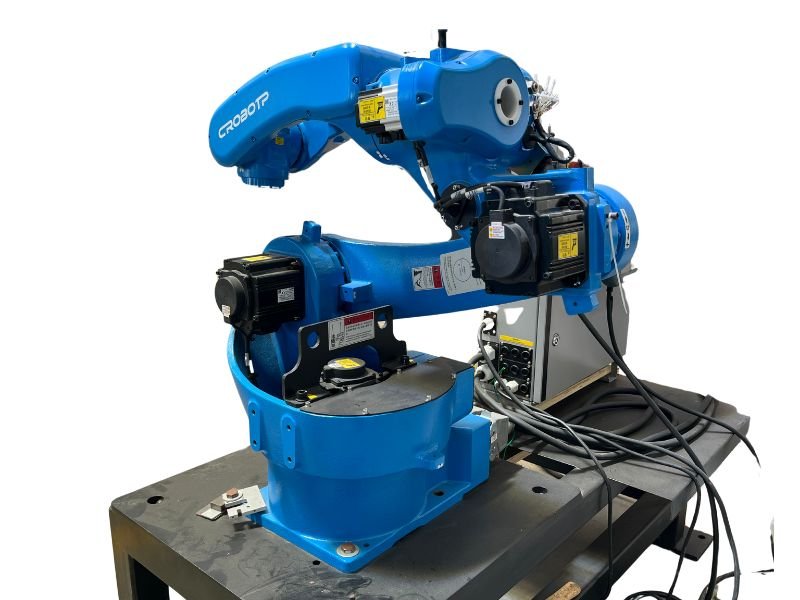

Fiber laser welding robot is equipped with a 6-axis robotic arm based on fiber laser welding to complete some difficult and dangerous tasks. It is more stable and has less deformation in welding. It can complete complex mechanical welding, has strong stability, small welds, and improves work efficiency.

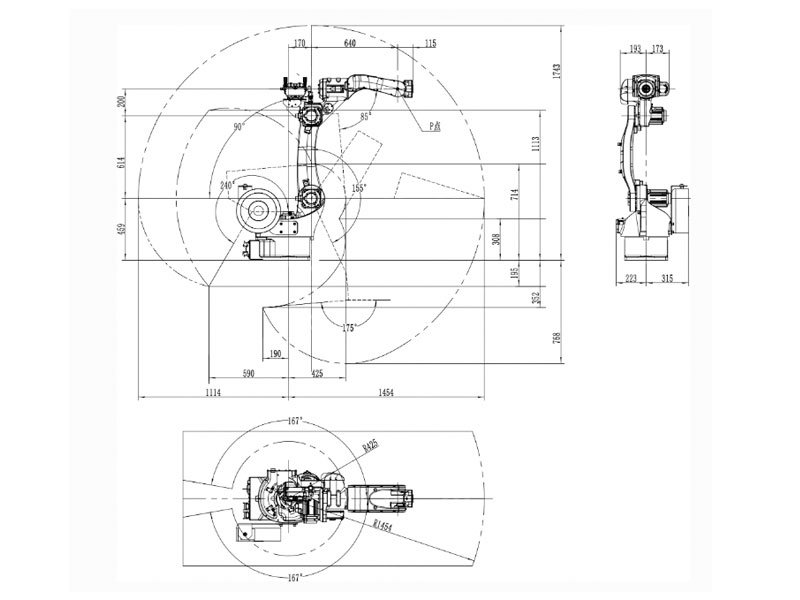

The six-axis robot laser welding machine consists of six joints: rotation (S axis), lower arm (L axis), upper arm (U axis), wrist rotation (R axis), wrist swing (B axis), and wrist rotation (T axis).

Laser welding robot is a professional welding system operating software, computer control program control, can realize automation, welding focus position is, welding quality is stable, welding depth is.

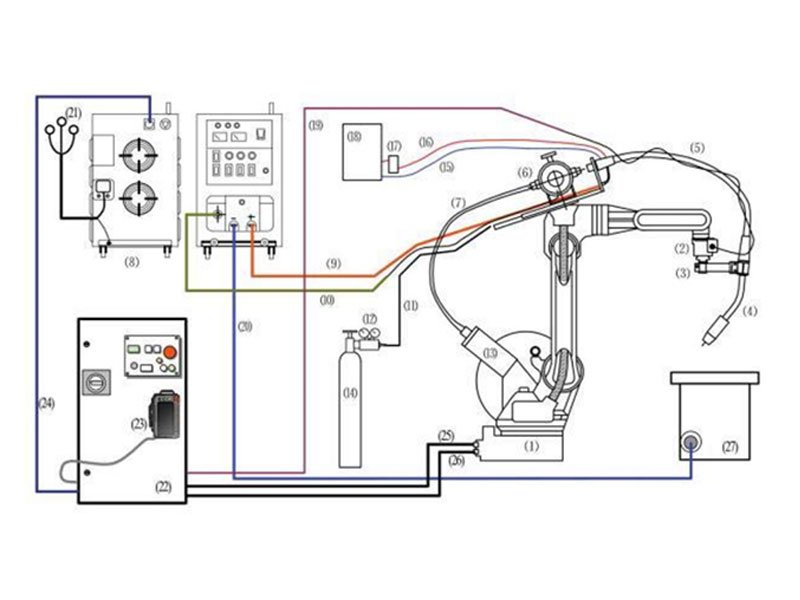

| No. | Name | No. | Name | No. | Name |

|---|---|---|---|---|---|

| (1) | Robot Body | (10) | Wire Feeder Control Cable | (19) | Collision Sensor Cable |

| (2) | Collision Sensor | (11) | Shielding Gas Hose | (20) | Power Cable (-) |

| (3) | Torch Holder | (12) | Shielding Gas Flow Regulator | (21) | Welding Power Supply Cable |

| (4) | Welding Torch | (13) | Wire Reel Stand | (22) | Robot Control Cabinet |

| (5) | Torch Cable | (14) | Shielding Gas Cylinder | (23) | Robot Teaching Pendant |

| (6) | Wire Feeder | (15) | Cooling Water Pipe | (24) | Welding Machine Communication Cable |

| (7) | Wire Conduit | (16) | Cooling Water Pipe | (25) | Robot Power Supply Cable |

| (8) | Welding Power Source | (17) | Water Flow Switch | (26) | Robot Control Cable |

| (9) | Power Cable (+) | (18) | Cooling Water Tank | (27) | Fixture and Workbench |

The arm span is 1.4 meters. The design is highly compact and can be flexibly installed on the ground or inverted.

It has a large working space, fast running speed, high repeat positioning accuracy, and is suitable for welding applications with a wide range of applications.

It is equipped with a safety emergency stop board independent of the control system, adopts a safety relay circuit, and provides a dual-circuit emergency stop to the outside to ensure the reliability of the emergency stop.

The main body cable adopts a high-flexibility robot-specific cable.

Built-in three-phase transformer, 380V and 220V are isolated, and the power supply is more stable. Built-in three-phase filter effectively improves EMC and EMI performance.

The main body provides a dual-circuit gas pipe to meet the needs of welding.

The inner diameter of the center hole of the 6-axis is 44mm, which can meet the installation requirements of water-cooled guns and bellows guns.

Built-in high-flexibility welding cable.

1. The six-axis industrial manipulator has a short response time, quick action and high speed. The robot does not stop or rest during operation, which improves the efficiency of automated production.

2. The six-axis industrial manipulator has high precision and less quality impact, thus ensuring the quality of the product.

3. The use of six-axis industrial robots can reduce labor costs, reduce the waste of raw materials, and significantly reduce costs.

4. The program can be modified to adapt to the production of different workpieces, shorten the product modification cycle and the application of equipment.

5. Replace manual work in high-risk and harmful environments, and liberate individuals from various harsh environments.

Branded laser MAX,RECI, RAYCUS,stable performance, higher photoelectric conversion rate, longer service life of 100,000 hours.

The laser welding head operates smoothly and cooperates with the robot accurately and effectively to ensure stable welding quality.

Equipped with a high-performance six-axis robot, it can achieve three-dimensional welding, easy to operate and highly intelligent.

Manual welding is a more traditional welding method, which will be gradually replaced by robot welding in all aspects. Robot welding has the advantages of high efficiency, high precision and high reliability, and plays an important role in modern industrial production.

Continuous operation: The robot can work 24 hours a day, greatly improving production efficiency.

Faster speed: The robot welding speed is much higher than that of manual labor, shortening the production cycle.

Batch production: Suitable for large-scale, repetitive welding tasks.

Higher precision: The robot welding precision is much higher than that of manual labor, and the weld quality is more stable.

Good consistency: The quality of each weld point remains highly consistent.

Fewer defects: Reduce welding defects caused by human factors.

In the long run, reduce costs: Although the initial investment is high, in the long run, the overall production cost can be reduced by improving efficiency, reducing defective rates, and reducing labor costs.

Reduce waste: Precise welding reduces material waste.

Reduce safety hazards: Robots can replace people to work in dangerous environments and reduce work-related accidents.

Reduced exposure to harmful gases: Reduce the risk of workers being exposed to harmful welding environments.

Wide adaptability: Through programming, robots can adapt to various complex welding workpieces and welding processes.

Easy to Program: Modern robot programming software is easy to operate and allows quick adjustment of welding parameters.

New energy industry

Batteries, motors, and electronic controls are the three core components of new energy vehicles. From automotive battery cell manufacturing to PACK assembly, the power battery structure covers a variety of materials, such as steel and aluminum, as well as copper and nickel. These metals may be made into electrodes, wires, shells, etc.

Auto parts industry

The combination of advanced laser processing technology and automobile production has become a general trend. Laser welding can not only adapt to the rapid welding of thin parts, effectively reduce the weight of the car body, and there is almost no spatter in welding, but also reduce the loss of processes and production materials, further improving production efficiency.

Do You Want to Buy fiber laser welding robot arm price? Fill Out This Form To Get In Touch.

Get the best robot laser welding machine system price and product catalog

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.