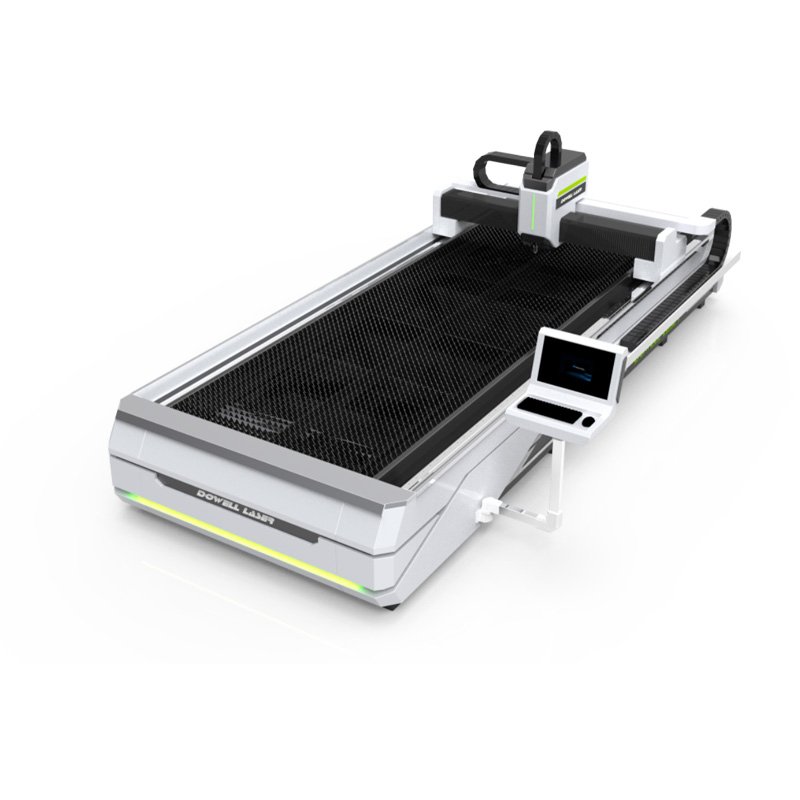

About Dowell sheet metal laser cutter supplier manufacturers

Dowell laser machine has been established for 13 years, a professional manufacturer and supplier of sheet metal laser cutter factories, exporting 1000w 1500w 2000w 3000w sheet laser cutting machine products are suitable for industrial and advertising industries, providing the most affordable discounted prices, exporting to the United States, Australia, South Korea, Saudi Arabia and other countries, Serving tens of thousands of customers, well received by customers.

We can carry out metal laser cutting design according to your needs.