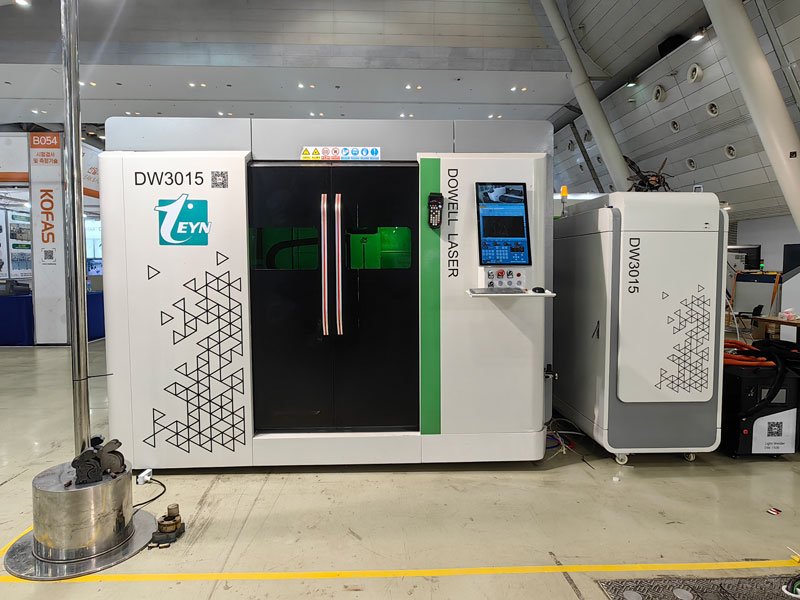

15 years steel laser cutter supplier

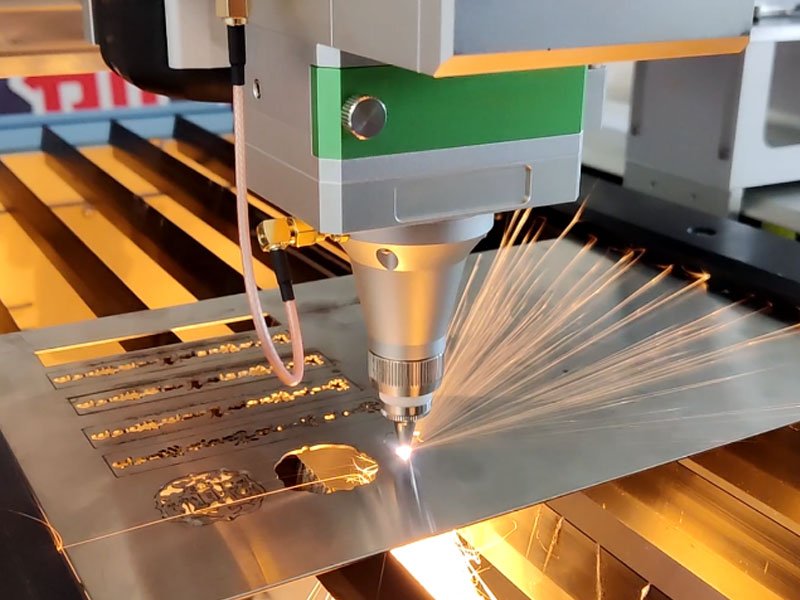

high precision steel laser cutting machine

DOWELL is the most popular professional Chinese steel laser cutting machine factory, who can customize the configuration, size, power, and color of the laser steel cutter, and provide you with the most affordable metal laser cutter price.