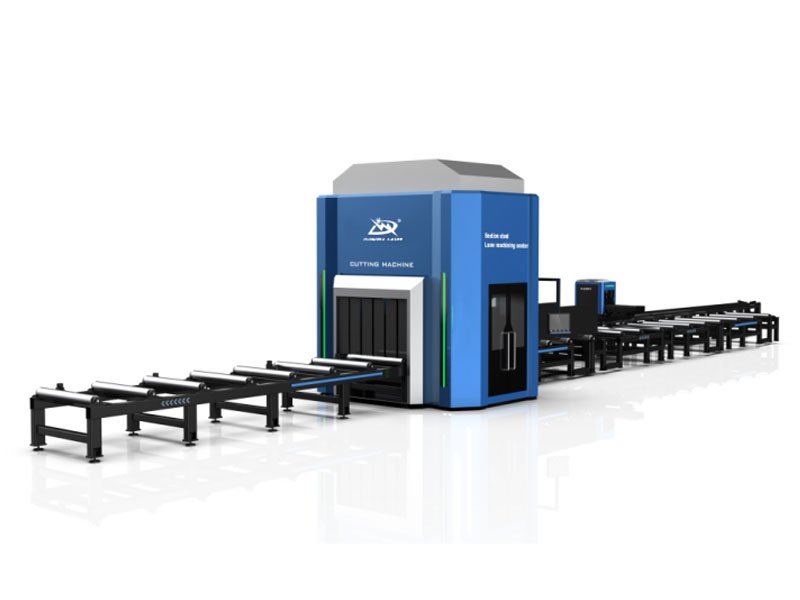

Structural steel laser cutting machines are a type of professional CNC equipment used to cut structural steel materials. It uses a high-energy-density laser beam to irradiate the surface of structural steel, causing the steel to melt or vaporize instantly, and blows away the molten or vaporized material through auxiliary gases (such as oxygen, nitrogen, etc.), thereby achieving the purpose of cutting. The energy source for laser cutting is mainly a laser generator, which produces a laser beam with extremely high energy concentration, which can accurately act on the cutting part.

Laser cutter for steel structures is ideal for a variety of applications in construction, heavy industry, and metal manufacturing. By adopting a concentrated laser beam, thick steel materials such as steel frames, beams, and profiles can be easily processed with minimal deformation.

High-strength aluminum material, 5-axis machining center milling, strong structure, high machining accuracy, good overall rigidity. Can be configured with a variety of laser cutting heads

Three-in-one cutting software: plane cutting, groove cutting, steel cutting

Beckhoff 3D six-axis CNC system

H-beam online measurement, compensation, cutting, hole opening, marking, cutting, groove opening integrated software functions

Modeling: It is convenient for customers to make drawings on site. According to the 2D and 3D paper drawings, the 3D model can be generated by directly inputting parameters

Seamlessly connected to TEKLA software, supports 3D drawing import, and supports industrial-level file formats (STP, IGS)

Rich process parameter settings, such as lead, compensation, starting point, part co-edge, part expansion settings, etc.

Automatic nesting: Supports nesting of multiple parts and multiple profiles in multiple ways, can nest at the same time, save material first, long and short materials, custom nesting, and can record historical nesting information

WisNest steel nesting software, compatible with Tekla, SW, CAD and other 3D format files

H-beam special process database: R angle, groove, wing plate, web plate, aerial cutting, through-weld hole and other cutting processes

Sturdy and durable, high rigidity, integrated ACU rotating swing mechanism

U-axis follow-up solution, flexible, convenient and fast

Laser equipment for steel fabrication, with its high efficiency and high precision, can process a variety of metal materials, including carbon structural steel, stainless steel, low alloy high strength structural steel, aluminum alloy, etc. This wide adaptability makes Steel framework laser cutter an indispensable and important tool in modern manufacturing, which can meet the needs of material processing in different fields.

Large supermarkets, stadiums, bridges, communication signal towers and other fields. High-precision steel structure laser can realize one-time forming of H-shaped steel cutting, beveling, locking, perforation and other processes.

I-beam: I-beam is a common building structure material, and Steel construction laser cutting equipment can cut it at high speed and effectively.

Channel steel: Channel steel is used in various building structures and bridge construction, and channel steel is cut accurately to meet specific design requirements.

Angle steel: Angle steel is widely used in buildings, bridges, towers and other structures, and Laser technology for structural steel can provide precise cutting services.

T-steel: T-steel is used in certain specific building structures, and Laser equipment for construction steel can customize its cutting.

Plates: Precision cutting for steel can also cut steel plates of various thicknesses, including carbon steel, stainless steel and other materials, suitable for straight cutting and bevel cutting.

Tubes (square tubes, round tubes): Industrial laser for steel construction can also process tubes, including square tubes and round tubes, for opening, truncation, bevel cutting and intersection line cutting

It is also used in the cutting of ship hull structural steel. Ship structural steel is generally thicker, but Metal structure laser cutting can still play its high precision advantage to cut out ship keels, ribs and other parts, improving the quality and efficiency of ship manufacturing.

Cutting structural parts such as automobile frames. The automobile industry has extremely high requirements for the precision and quality of parts. Steel frame laser processing machine can quickly and accurately cut out key parts such as automobile frames, and can adapt to the automated production lines of the automobile industry.

Manufacture various mechanical structural parts, such as machine tool beds, parts of engineering machinery, etc. In these fields, the precision and quality requirements for structural steel parts are high. Laser machine for steel frameworks can meet these requirements and can be customized according to different mechanical design requirements.

Used to cut various beams, columns, connectors, etc. in building steel structures. For example, in the manufacture of steel structure frames of high-rise buildings, Steel frame laser cutting machine can accurately cut out steel components that meet the design requirements to ensure the strength and stability of the building structure.

Our DOWELL LASER is equipped with the latest High-precision steel structure laser, designed to meet the most stringent industrial standards. These advanced laser cutting machines have earned a reputation in the domestic and international markets for their Advanced laser cutter for steel frameworks capabilities. We are proud to announce that our Thick steel laser cutting capabilities and Heavy industry laser cutting technology have pushed the depth and breadth of laser cutting to new heights.

We always adhere to customer-centricity and provide a full range of services from design to delivery. Whether it is Laser cutter for structural frames or Fiber laser for structural metal, we can ensure that every device meets the highest quality standards. Our goal is to enable every customer to get the perfect cutting solution of their dreams through Custom laser cutting for steel structures services.

Routine maintenance includes cleaning the lenses and mirrors, checking the laser alignment, inspecting gas supply systems, and lubricating moving parts. Regular maintenance ensures the machine operates at optimal efficiency and prolongs its lifespan.

Power requirements vary depending on the laser power and machine size. High-precision steel structure lasers may need dedicated industrial electrical setups, while smaller models can operate on standard industrial power supplies.

Operators should wear proper protective gear, such as laser safety glasses, and be trained in laser operation and safety procedures. Additionally, ventilation is essential to avoid inhaling fumes generated during the cutting process.

Yes, most machines are equipped with CNC systems and can be easily integrated into automated production lines. This feature makes them suitable for high-volume production while reducing manual labor and increasing efficiency.

Most Fiber laser for structural metal machines are compatible with popular CAD/CAM software, such as AutoCAD, SolidWorks, or proprietary CNC software, which allows users to design complex shapes and import files for precise cutting.

With proper maintenance, these machines can last anywhere from 8 to 15 years or more. The lifespan depends on factors like usage intensity, maintenance quality, and working environment.

Advanced laser cutter for steel frameworks cutting speed and quality depend on laser power, material thickness, type of steel, and machine settings. Higher power usually results in faster cutting, while adjustments to focus, gas flow, and speed are essential for optimal quality.

Operational costs include electricity, gas (for some machines), and maintenance expenses. While laser cutting may have higher initial setup costs, it often provides savings in speed, precision, and reduced post-processing time, making it cost-effective in the long run.

Do you want to know more about 3Heavy-duty steel laser cutting machine now? You can tell us the material to be cut and the required power, and we will arrange for a professional engineer to contact you.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!