Square tube laser cutting machine is a highly efficient laser cutting equipment, specially designed for square tube processing and rectangular tube cutting, which can achieve high-precision and high-speed metal cutting.

Application field: widely used in sheet metal processing, furniture manufacturing, automobile manufacturing and other industries.

Advantages: high efficiency, low cost, good quality, easy operation, can realize automated production and CNC processing.

This article mainly explains the square tube laser cutting machine to you, please continue to read the following article.

High-speed cutting: Using fiber laser technology, the cutting speed is fast, which greatly improves production efficiency.

High-precision cutting: High cutting accuracy, meeting the processing requirements of precision parts.

Flexible production: Supports customized processing and adapts to the cutting of square tubes of different shapes and sizes.

Automated production: Realize automated production lines and reduce labor costs.

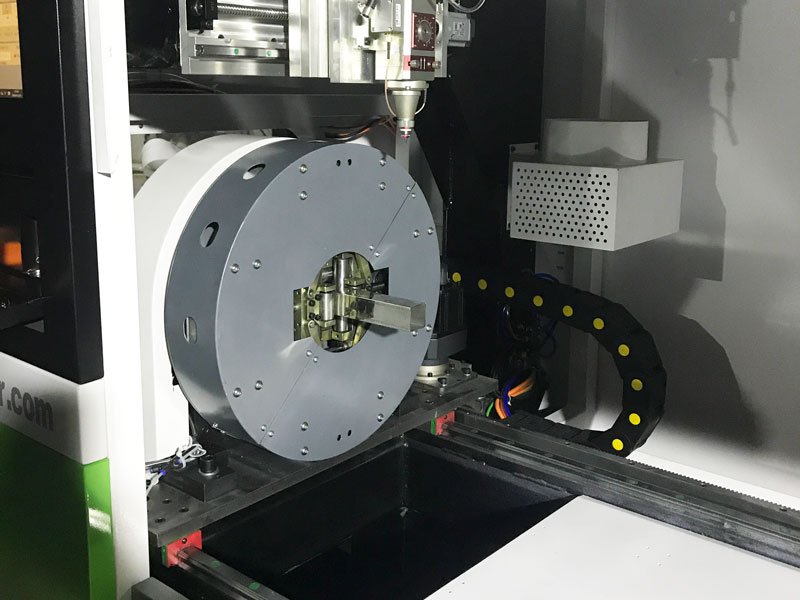

Fiber laser, laser cutting head, laser cutting system, water cooler, guide rail, rack and pinion, rotating system, bed

Automatic loading system: improve production efficiency and reduce manual operation.

Multi-axis control capability: allows complex cutting paths and increases processing flexibility.

Software compatibility: ensures compatibility with your existing CAD/CAM system.

Cutting head type: Fiber optic cutting heads are generally more suitable for metal cutting.

The fiber laser cutter price above is about USD 25,000-90,000. The brand, power size, configuration, and after-sales service also have a great impact on the laser cutter machine price.

If you want to buy an affordable price, you need to compare with multiple companies

It can cut stainless steel, carbon steel, copper, aluminum and other metal pipes.

It can cut common pipes such as round pipes, square pipes,rectangular tube and ovals, as well as various types of steel and special-shaped pipes such as angle steel, channel steel, I-beam, and H-beam.

The laser cutting chuck can be adjusted manually and automatically and can be operated automatically only by operating the button. The holding force is stable and efficient, and the size is adjustable.

Reduce cumbersome manual procedures; one person operates multiple devices, increases work efficiency by five times, and batch processing is possible.

There is no need to rotate the cylinder, and it is equipped with a chuck and a gyrator. Compared with the traditional chuck, the structure is simpler, the installation is convenient, the load on the spindle is reduced, and the machine’s life is extended.

The chuck is a fully enclosed structure, and its service life is much higher than manual chucks. The life span can reach five years. The clamping accuracy is generally 0.01-0.03 mm, and the limit speed is 3000 rpm.

With a self-locking function, the workpiece can be firmly clamped for cutting when the power is off, which solves the safety problem.

We have a professional design team, and it is possible to customize the laser cutting tube drawing design, size, size and power of your product.

Polyethene cannot be cut, and harmful smoke will be produced, which will cause harm to the body of the operator and the laser pipe cutting machine itself.

The laser cutting square tube is suitable for polycarbonate below 1mm, and it will also cause the colour of the raw material to fade.

The high-energy temperature generated by the laser can volatilize raw materials, but it is not suitable for related materials such as ABS and polyethene plastics.

Cutting polyethene and polypropylene foam with a laser tube cutter is prone to fire.

Do You Want to Buy the best square tube laser cutting machine? Fill Out This Form To Get In Touch.

Get the latest high quality square tube cutting machine laser price and product catalogue

DOWELL Laser has 13 years of experience manufacturing laser cutting equipment, one-stop laser cutting solutions, and pipe laser cutting equipment for cutting round, square, rectangular, and channel steel. The company has a standard production process, and each department has dedicated personnel responsible. The machine is tested before delivery to ensure that it can be used normally when you receive it.

Solution: Check whether the mainboard parameters are correct, stop the machine and check the mainboard parameter settings

Solution: Unplug the motherboard sensor; if the machine does not move, if it moves, replace it with a new sensor.

Solution: Check whether the motor wire or the motor shaft is broken, and if so, replace the motor wire or small motor.

Solution: Check the motherboard parameters, whether the X-axis or Y-axis can stop; if correct, check the motherboard or sensor, replace and rule out.

Choosing a square tube laser cutting machine is an important investment decision. By comprehensively considering technical parameters, functional characteristics, brand reputation, safety and environmental protection factors, and return on investment, you can choose the most suitable equipment for your business. Remember, this is not only an equipment purchase, but also a strategic investment in the future development of the company. Choosing the right square tube laser cutting machine will bring long-term competitive advantages to your business.

Power requirements:

The power of laser cutting machines is usually between 2000W and 6000W. The greater the power, the stronger the cutting ability and speed, but it will also increase energy consumption. For example, a 2000W laser cutting machine can consume 30-40 kWh of electricity per hour when running at full load. Calculated at 1 yuan per kWh, the operating cost is relatively high.

Energy consumption of other equipment:

In addition to the laser generator, the laser cutting machine also requires multiple auxiliary equipment, such as water coolers and air compressors. The power consumption of these equipment will also significantly increase the overall energy consumption. For example, a water cooler usually requires more than 20KVA of electricity, and an air compressor requires at least 5KVA.

Working hours:

The actual energy consumption of a laser cutting machine is closely related to its working hours. The amount of electricity consumed by a machine when it is working is proportional to its power, and long-term operation will result in higher electricity bills. For example, if a 35kW laser cutting machine is running for 8 hours a day, its daily electricity bill can reach $33.6.

Standby mode:

The laser cutting machine also consumes a certain amount of electricity when it is in standby mode. Although the energy consumption is lower when in standby mode, this part of the cost still needs to be considered. Some modern equipment is equipped with energy-saving functions to reduce energy consumption when in standby mode.

The impact of material type on energy consumption

Different materials have different cutting difficulties and required time, which directly affects energy consumption. For example, cutting steel usually requires higher power and longer time than aluminum or copper, so it consumes more electricity.

Fiber laser cutting technology:

Compared with traditional CO2 laser cutting machines, fiber laser cutting machines have higher electro-optical conversion efficiency, energy efficiency has been improved by 3 times, and the overall energy consumption is only 20-30%4 of similar CO2 laser cutting machines. This makes fiber laser cutting machines more economical and environmentally friendly in long-term operation.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!