Water guided laser technology, also known as laser microjet cutting and micro water guided laser technology, is an advanced laser processing technology.

Laser MicroJet laser technology integrates six elements, water, light, machinery, electricity, computing, and gas, to work together on one platform, coupling the laser into a fine water jet, and then processing the material.

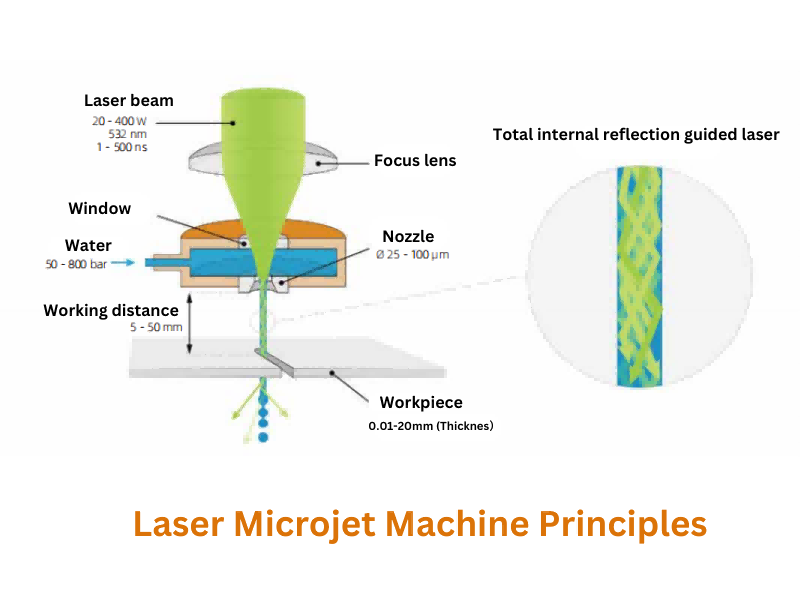

Water jet guided laser cutting machine is an advanced laser and photon manufacturing technology that uses the phenomenon of total reflection of laser at the interface between water and air to confine the laser in a micro-water jet with a diameter of tens of microns. The water jet maintains an extremely high laser energy density, thereby achieving material removal.

Due to beam divergence, the working distance of conventional focused laser beams is limited to a few millimeters to a fraction of a millimeter. This not only requires precise focusing and distance control, but also limits the ratio of kerf width to depth.

Laser microfluidization uses a laser beam that is fully reflected by the air-water interface. The beam can be directed over distances of up to 10 cm, allowing for parallel, high-aspect ratio cuts. No focus or distance control is required.

Water jet guided laser can meet the needs of complex and precise processing, and can be used for high-precision cutting and drilling of metals, liquid metals, semiconductor materials, ceramics, silicon carbide, diamond, thermal barrier coatings, cemented carbide, Kovar alloy, carbon fiber composite materials, etc.

Water jet guided laser equipment cuts hard, brittle and tough materials such as silicon carbide, single crystal nickel-based alloys, Kovar alloys, liquid metals, carbon fibers, zirconia ceramics, etc., and the processing achieves no taper but depth, no heat-affected zone, high precision, high efficiency, and a yield rate of over 99%.

Realize 3D cutting processing, superhard materials, metals, ceramics, etc.

High precision and high efficiency make it an ideal choice for solving material processing problems in the aerospace field. In the cutting of aircraft fuselages, wings and engine parts, it can provide high-precision processing to meet the high requirements of part precision in the aerospace field.

Used for cutting printed circuit boards, electronic components, etc. Its high precision and high speed can improve production efficiency, reduce manufacturing costs, and meet the demand for high-precision parts in the electronic manufacturing field.

Used for cutting body panels, engine parts and chassis, etc., to achieve fast and accurate processing of complex-shaped parts, improve production efficiency and reduce manufacturing costs.

Do you want to know more about cnc water jet cutting laser machining equipment now? You can tell us the material to be cut and the power required, and we will arrange professional staff to contact you.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!