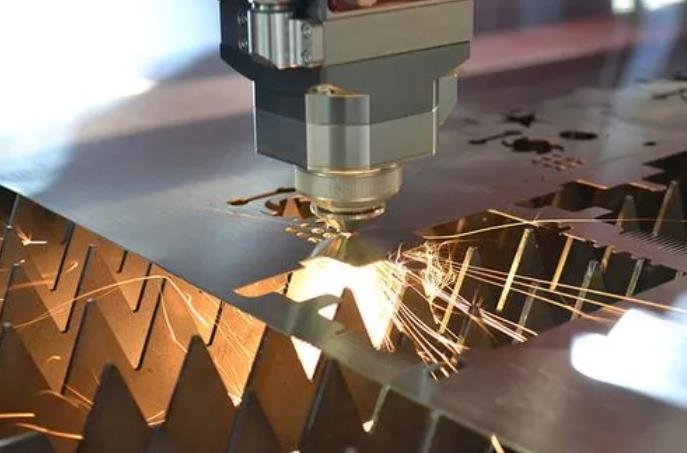

Continuous overloading of metal laser cutting equipment in summer will cause the machine to fail to perform well and even reduce its service life, so pay attention to the maintenance of laser cutting equipment in summer.

1.Check the layout in advance and set the pressure inside the cooler before the high temperature weather arrives.

(The pressure of equipment used by each manufacturer is different, please consult the manufacturer for specific settings)

2.The electrical cabinet of the laser cutting machine should be dust-treated, and check whether the cooling fan (use distilled or purified water) is working normally.

Scale is cleaned regularly to prevent clogging the laser pipeline

(Note: Operate under the guidance of the equipment)

3.The water temperature and air temperature should not differ too much.

The water temperature is set at about 30-32 degrees, and the water temperature and room temperature are lower than 7 degrees. The laser and optical lenses of the metal laser cutting machine should be cooled with water.

If the water temperature is too low, it will cause condensation on the surface of the laser, which will affect the power of the laser and reduce the service life.

If you want to save the cost of laser cutting machine, you need to maintain it frequently.