Lasers seem to be very far away from people’s production, but when you look closely, you will find that lasers are often seen in our daily lives, and even ubiquitous. The main uses of laser cutting machines are also very diverse, especially in industrial production and manufacturing.

For most metal materials, laser cutting can be carried out very well in a short time regardless of the intensity. What manufacturing industry can the metal laser cutting machine be used in? Come, let’s introduce it in detail together.

Sheet metal processing plant manufacturing industry

Laser cutting can be described as a major transformation and transformation in the sheet metal processing plant. Because of the high level of flexible production of laser cutting, fast laser cutting speed, high laser cutting efficiency, and short equipment work cycle, it immediately becomes a sheet metal processing plant manufacturing industry. The new favorite of laser cutting, laser cutting has no cutting force, no deformation in production; no tool wear, no matter what kind of part, it can be laser cut with a fine and short time laser cutting.

In addition, the laser cutting slits are generally narrow, and the laser cutting quality is good, the intelligent system is high, the labor efficiency is low, and there is no pollution. In the production of spare parts cabinets and iron file cabinets, they are generally manufactured in standardized production of thin metal sheets. The use of laser cutting machines for laser cutting production is more efficient and more efficient, and laser cutting production regulations can be implemented in a shorter time.

Agricultural machinery industry

The excellent laser processing technology, drawing system and numerical control technology of the laser cutting machine are all used in the production and manufacturing of agricultural machinery equipment, which has accelerated the development and growth of the production and manufacturing of agricultural machinery equipment and improved economic benefits. Reduce the manufacturing cost of agricultural machinery and equipment.

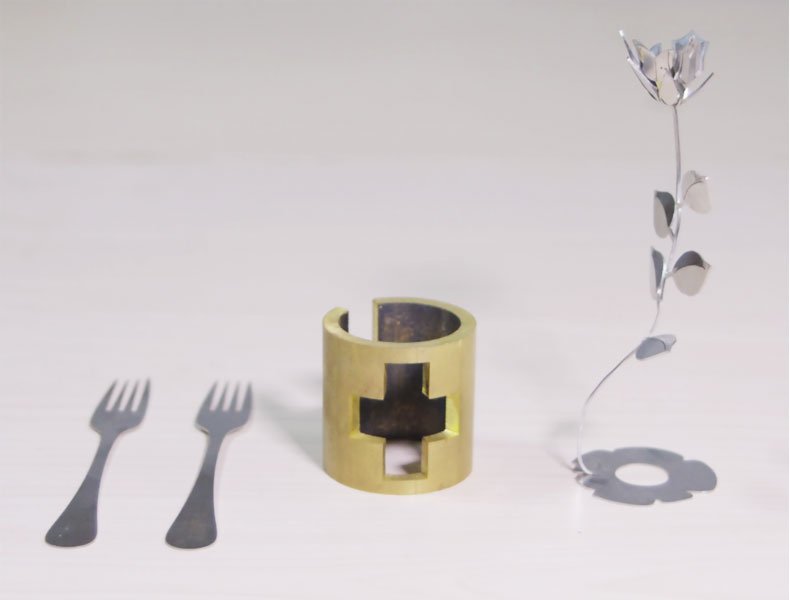

Advertising production and manufacturing industry

In the advertising production and manufacturing industry, more metal materials are generally used. However, the traditional advertising product production equipment, the processing accuracy and laser cutting surface are not ideal when producing advertising fonts and other material content, resulting in a very high probability of rework. Shocked, not only cost a lot of costs, but also greatly reduced work efficiency.

If laser cutting machine equipment is used to produce advertising products, not only can the above-mentioned series of problems be effectively solved, and the actual effect of advertising materials can be displayed well, but also the high production efficiency can be greatly improved, and the real low investment and high return can be achieved. In addition, laser cutting machine equipment can also carry out the production of certain complex graphics, which expands the scope of equipment business processes of advertising media companies, and promotes a significant increase in the additional profits of micro-enterprises.

Machinery and equipment manufacturing industry

Agricultural machinery is a key component of China’s economic development, and China is an export of machinery and equipment

In the future, the machinery industry will be a key downstream sales market for the marketing, promotion and development of laser cutting equipment. Although most of the machinery industry now uses traditional cutting methods, only a small part of high-end processing plants choose computer-controlled numerical control equipment to carry out intelligent system board cutting, but the proportion of intelligent system laser cutting equipment in the machinery industry It will undoubtedly become bigger and bigger, and effectively increase the production efficiency of machinery and equipment.

Kitchenware manufacturing industry

In the kitchen appliance manufacturing industry, range hoods and gas appliances generally use a lot of sheet metal control panels. This kind of sheet metal control panels generally have low work efficiency when produced by traditional production methods, and they are moldy. The high cost and increased operating cost not only cost a lot of manpower, material and financial resources, but also restrict the development and design of new products.

The laser cutting machine can avoid this headache. In the production of kitchen equipment equipment, the laser cutting speed of laser processing equipment is extremely fast, and the laser cutting precision is extremely high, which not only greatly improves the high production efficiency, but also effectively improves the yield of range hoods and gas appliances.

In addition, the laser cutting machine is also more suitable for laser cutting of thin metal plates and stainless steel plates, which can better complete the development of customized and differentiated products, and is excellently compatible with the kitchenware manufacturing industry.

The automotive industry

In the automotive industry, certain parts such as car doors, car silencers, etc. will have some unnecessary edges or burrs after being formed. If manual or traditional methods are used for production, it is difficult to ensure accuracy and high efficiency. If you choose a laser cutting machine for processing, you can easily deal with edge and burrs in batches.

As one of the industries with the largest level of intelligent systems, the automobile industry has integrated a variety of production processes, and laser, as one of the most important technologies, has completed up to 70% of the intelligent production of spare parts.

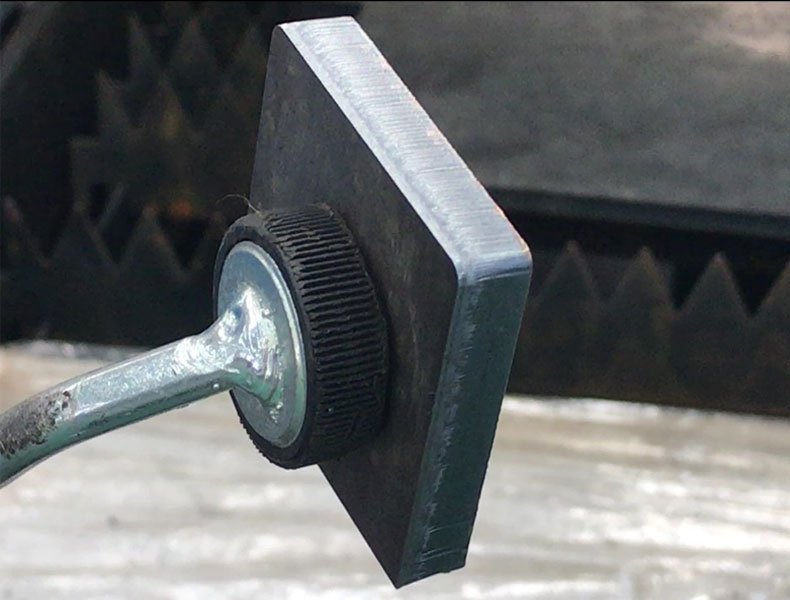

Fitness equipment

The fitness equipment placed in the gymnasium and the square are basically made up of pipe fittings. The pipe laser cutting machine can be used to more conveniently and quickly laser cut the corresponding pipe fittings for the manufacture and assembly of fitness equipment.

Aerospace

Laser manufacturing technology is a key component in the field of aerospace manufacturing technology. Laser cutting production technology has now been widely used in aircraft, aerospace rockets and other parts, components and other components.