In today’s industrial development, in the metal manufacturing industry, the precision and efficiency of lasers that cut through metal are very important. This article will take you to understand the field of laser cutter metal, laser cutting machine technology, and how CNC laser cutting equipment cuts metal sheets.

Laser cutting machine: changer in the metal cutting

The emergence of laser cutting technology

At first, laser cutting for metal was produced for the military and industry, and was later used by many metal manufacturers. This technology has high precision and fast speed, and gradually replaced traditional metal cutting equipment.

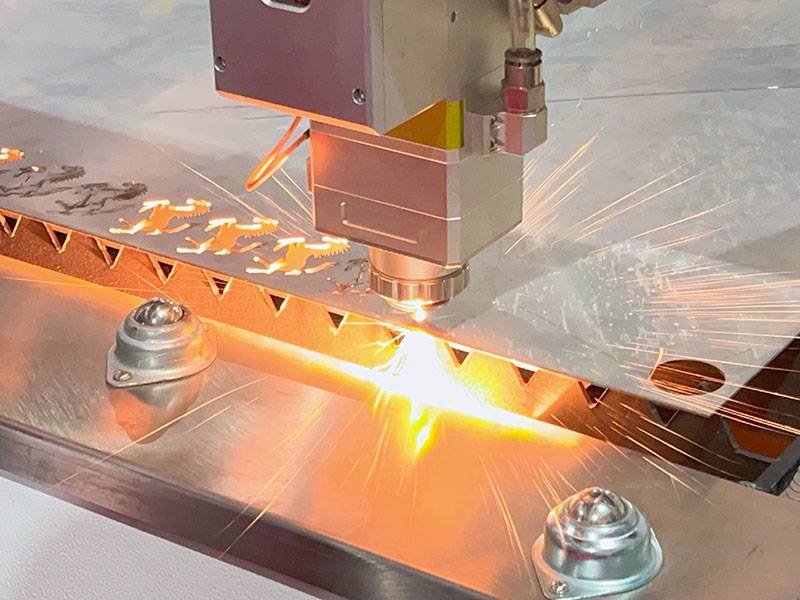

Cutting machine principle

With high operating precision and fast speed, the laser source generates a beam that is focused through the lens to achieve the purpose of cutting. You can cut any image without restrictions.

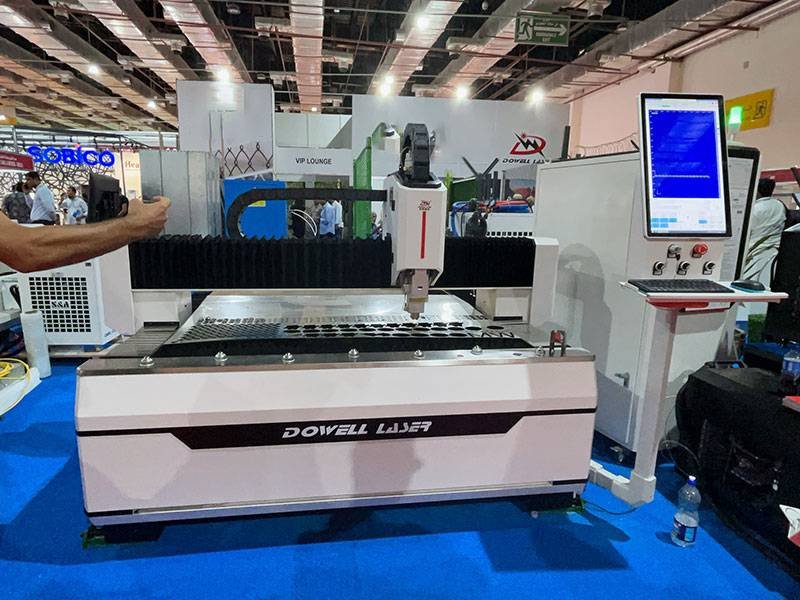

CNC Technology and laser to cut metal

The perfect cooperation between CNC technology and laser cutting machine improves cutting accuracy, and its advantages in metal processing are extremely prominent.

Cutting different metal materials

Steel is a material often cut by laser cut steel machine, and it can also cut brass, aluminum plates, titanium, etc. Different materials have different cutting requirements. Choosing the appropriate laser cut machine for metal can achieve the best results.

Benefits of using a laser to cut steel parts

Laser cutting steel parts has many advantages. Small thermal deformation ensures material integrity, reduces secondary processing and grinding, shortens time, and improves work efficiency.

The steel parts produced by laser cutting are not only strong, but also beautiful, meeting functional and visual requirements.

Application of laser cutting steel in various industries

Automotive manufacturing, steel construction, aerospace, elevator manufacturing, agricultural machinery production, kitchen appliances and more. Steel cutting lasers can meet many different customized needs.

The future of metal manufacturing

Numerical control laser cutting Development

The future development of metal manufacturing is inseparable from numerical control laser cutting technology. The continuous development of fiber lasers is getting closer to high power and thicker cutting materials. With automated production equipment, the process is simplified and production efficiency is further improved.

Sustainable development

Laser that cuts through metal minimizes material waste and saves resources. It is an efficient and economical choice for manufacturers.

FAQ

How does CNC technology improve accuracy?

CNC technology improves precision by reducing human factors in the cutting process, with computers controlling the motion process of cutting and CNC system operations.

How to ensure safety during the cutting process of laser cutter

Operators receive professional technical training before taking up the job, strictly follow the operation manual, and wear safety glasses and gloves. Ensure air quality in a well-ventilated environment.