One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

Cars are an essential means of travel for modern families. Laser cutting in the automotive industry is widely used in the cutting of auto parts, not only for cutting auto parts, but also for welding, cladding, engraving and marking, etc.

Laser cutting systems and laser welding are usually the mainstays. Laser cutting includes planar cutting and three-dimensional cutting. For some high-strength steel structural parts with complex contours, laser cutting is a very effective processing method both from a technical and economic point of view.

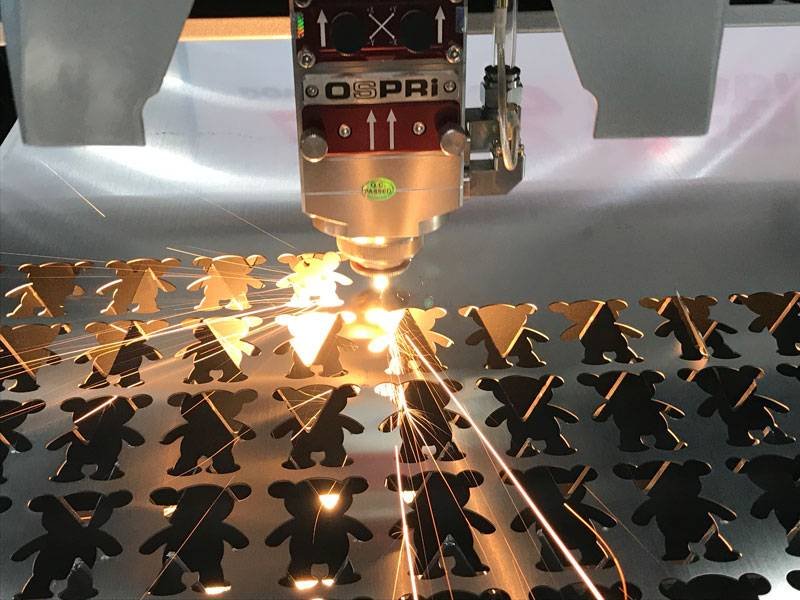

The CNC cutting equipment provided by DOWELL laser cutting system manufacturers can be applied to industrial laser cutter accessories. It can cut any metal materials such as stainless steel, carbon steel, ceramics, titanium, etc., and can cut in large quantities.

Laser cutter parts: car door sheet metal cutting, car brake pads, car wheels, car precision parts and so on.

1. Save production cost

There is no need for molds, which can save mold investment, cut products without secondary polishing, eliminate unnecessary processing procedures, and reduce production costs.

2. Improve production efficiency

Compared with traditional cutting, laser cutting has high positioning accuracy and fast cutting speed, which is conducive to directly shortening the processing and manufacturing cycle and improving production efficiency.

3. High cutting quality

It can accurately cut complex patterns, the cutting surface has no burrs, and the product quality is better.

4. Large processing area

The large-scale processing form can realize the whole plate cutting.

5. Low maintenance cost

The laser cutter machine has stable performance, is durable, can work continuously, and is not easy to be damaged

Step 1: Choose Material

The material of the metal workpiece will also have a certain impact on laser cutting. The thickness and size of the material need to be taken into consideration.

Step 2: Design

Laser cut cnc machine can improve the accuracy of cutting, technical operators only need to control the power and depth of laser cutting.

Step 3: Laser Setup

There are four settings an operator should keep in mind when setting up a laser cutter:

Laser power: High power lasers can cut workpieces and finish products faster than low power lasers.

Wavelength: Wavelength helps determine how well a laser beam heats, melts, and cuts a workpiece.

Beam Mode: The beam mode measures the intensity of the beam and the diameter of the laser focal spot. It will affect the accuracy and quality of cutting.

Focal Spot: The focal point varies in size and alignment. Spread points or misaligned points will produce lower quality cuts.

Laser cutting cannot be used for parts processing with high precision requirements

After heating, the surface will be deformed by heat, and laser cutting parts that require a flat surface cannot be used.

The processing speed of laser cut car is slow. Compared with other processing methods, the speed of laser cutter parts is very slow. In some complex and fine processing, it is difficult for the cnc laser cutter steel to achieve the expected effect.

Laser auto parts are subject to changes in the surrounding environment, which can make parts difficult to produce or not function properly.

Metal materials such as carbon steel materials within 12mm and stainless steel materials within 10mm that are often used in laser cut cars can be processed by laser cutters. It is generally recommended to choose laser cutting parts of 3000w or 4000w, which can be equipped with large enclosures and exchange platforms, which are safer and more efficient.

| Thickness (mm) | Suitable Power (W) |

|---|---|

| 3-5 | 1000w laser cutter |

| 5-8 | 1500 watt laser cutter |

| 8-10 | 2000w laser cutter |

| Up to 13 | 3000w laser cutter |

| Up to 40 | 12000 sheet metal laser cutter |

| Up to 60 | 20000w laser cutter metal |

Choose the cutting machine power that suits you according to the display. If it is a relatively thin metal material, we can choose 1000W, which can not only ensure a higher cutting speed, but also save costs. Of course, if it is for a relatively thick metal material, you can Choose a high-power cutting machine. A high-power cutting machine can not only guarantee the cutting effect, but also have a better cutting effect.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.