Popular Fiber Laser Cutting Machine China Manufacturers & Exporters

DOWELL LASER is a laser cutting machine manufacturers in china with 15 years of manufacturing experience, committed to providing customers with one-stop laser cutting solutions.

DOWELL LASER is a laser cutting machine manufacturers in china with 15 years of manufacturing experience, committed to providing customers with one-stop laser cutting solutions.

We have a professional technical research and development team to provide you with the most comprehensive technical support and training, and provide you with the most affordable best chinese laser cutter price.

Suitable for cutting thick plates over 20mm, mainly used in large industrial markets

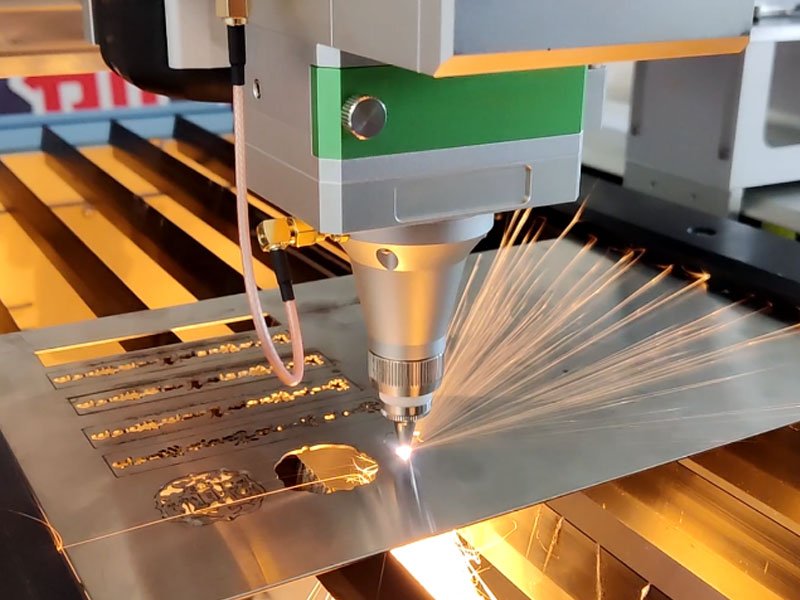

Cutting thin plates, stainless steel, carbon steel, aluminum, brass and other metal plates

Pipe laser cutter machine supplier, cutting round pipe, square pipe, special-shaped pipe and other metal pipes

Small work surface, suitable for home or DIY use, simple operation, convenient and quick to use

Fiber laser cutting technology is widely used in manufacturing due to its precision, efficiency, and versatility. It is applied in industries like metal fabrication, automotive, aerospace, electronics, and medical device manufacturing to create intricate, high-quality components. Other sectors, such as signage, fashion, and architecture, use laser cutting for customized designs and detailed work. Its ability to handle a variety of materials, from metals to textiles, makes it an essential tool for rapid prototyping, mass production, and custom manufacturing, offering manufacturers faster production with minimal waste.

Laser cutting machine manufacturers in china, can guarantee fast delivery

Laser cutting machine manufacturers in china, can guarantee to provide you with the lowest price

Can provide OEM ODM technical support

Products are exported to 80+ countries, serving 1000+ customers

It depends on the thickness and size of the board you want to cut.

If cutting metal with a fiber laser cutting machine, cutting non-metal carbon dioxide laser cutting machine.

Metal sheets below 10mm use 1000w laser cutting equipment.

When choosing, you need to understand the production qualification, production scale, brand reputation, quality problems and after-sales service of laser cutting machine manufacturers.

Purchasing cnc fiber laser cutting machine china may involve finding a reliable manufacturer, wholesaler or distributor online. Here are some popular platforms where you might find a metal laser cutter:

Alibaba: This is one of the most popular platforms to buy industrial machinery directly from Chinese manufacturers or wholesalers.

Made-in-China.com: Similar to Alibaba, Made-in-China.com is a platform for various Chinese manufacturers and suppliers.

AliExpress: The retail version of Alibaba, it caters more to small businesses and individual consumers.

DHGate: Another e-commerce platform connecting buyers with Chinese wholesalers and low-volume manufacturers.

There are 1000w 1500w 2000w 3000w 4000w 6000w 8kw 10kw 12kw 5kw 2kw 30kw metal laser cutter for sale in the market, if you want to know the specific laser cutting machine china price, you can contact the supplier, manufacturer or exporter.

Laser cutting equipment manufacturers in China have Shenzhen, Wuhan, Suzhou and Jinan where four manufacturers are relatively concentrated.

Yes, dowell co2 laser engraving and cutting machine is mainly used to cut non-metallic materials, leather, paper, cloth and other non-metallic materials.

| Aspect | CO2 Laser | Fiber Laser |

|---|---|---|

| Technology and Wavelength | Uses a gas mixture (CO2), operates at a wavelength of 10.6 microns. Best for non-metal materials. | Uses optical fibers doped with rare-earth elements, operates at 1.06 microns. Ideal for metals. |

| Cutting Speed and Efficiency | Slower cutting speed for metals, more effective for non-metals. Requires more maintenance. | Faster cutting speeds, especially for metals. More energy-efficient and requires less maintenance. |

| Material Compatibility | Works best with non-metals like wood, acrylic, and textiles. Can cut metals, but less efficiently. | Best for metals such as steel, aluminum, and copper. Less effective for non-metals. |

| Maintenance and Lifespan | More maintenance due to moving parts and shorter lifespan. | Minimal maintenance with a longer lifespan, often exceeding 100,000 hours. |

| Cost | Lower initial cost but higher operational and maintenance expenses. | Higher upfront cost but lower long-term operational and maintenance costs. |

Metal laser cutting solutions offers both high speed and precision. The cutting speed depends on factors like material type, laser power, and thickness, with fiber lasers excelling in metal cutting. Accuracy is achieved through focused beams, minimizing heat-affected zones, and ensuring tight tolerances. Although there can be a trade-off between speed and accuracy, modern machines allow operators to balance both for efficient, precise results, making laser cutting ideal for various industrial applications.

1. Technological innovation

Chinese manufacturers invest heavily in R&D to produce advanced laser cutting machines equipped with fiber laser technology. These machines feature high cutting speed, precision and efficiency and are suitable for a wide range of applications in different industries.

2. Cost-effectiveness

One of the main advantages of Chinese sheet metal laser cutting machines is their affordable price. Competitive prices allow global businesses to obtain high-quality machines without breaking their budgets. This cost-effectiveness makes Chinese machines attractive to companies looking to optimize production costs.

3. Diverse product range

China offers a wide variety of sheet metal laser cutting machines to meet different needs – from compact machines suitable for small-scale operations to heavy-duty models suitable for large-scale manufacturing. This diversity ensures that manufacturers can find the right solution for their specific requirements.

4. Growing export market

The export of Chinese laser cutting machines has expanded significantly, with the main markets being North America, Europe, Southeast Asia and Africa. The combination of quality, performance and price has led to an increase in demand for Chinese machines in these regions.

5. Quality assurance

Chinese manufacturers have improved the quality of their laser cutting machines, and many now comply with international standards and certifications, such as CE certification. This commitment to quality ensures that their products can compete effectively in the global marketplace.

6. Customization and Flexibility

Many Chinese manufacturers offer customizable laser cutting solutions, enabling customers to tailor the machine to their specific operational needs. This flexibility enhances their appeal in a competitive global marketplace.

Dowell Chinese laser machine suppliers We can provide you with professional customization services. If you want to buy affordable Affordable laser cutting machines equipment, you can consult us.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.

Social Chat is free, download and try it now here!