One-stop metal laser cutter solution

Jinan, Shandong, China

86-18654506392

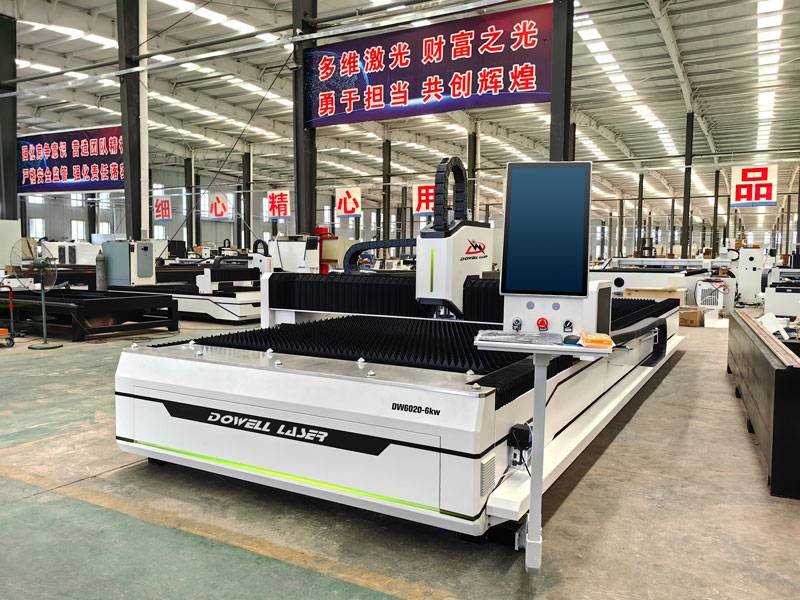

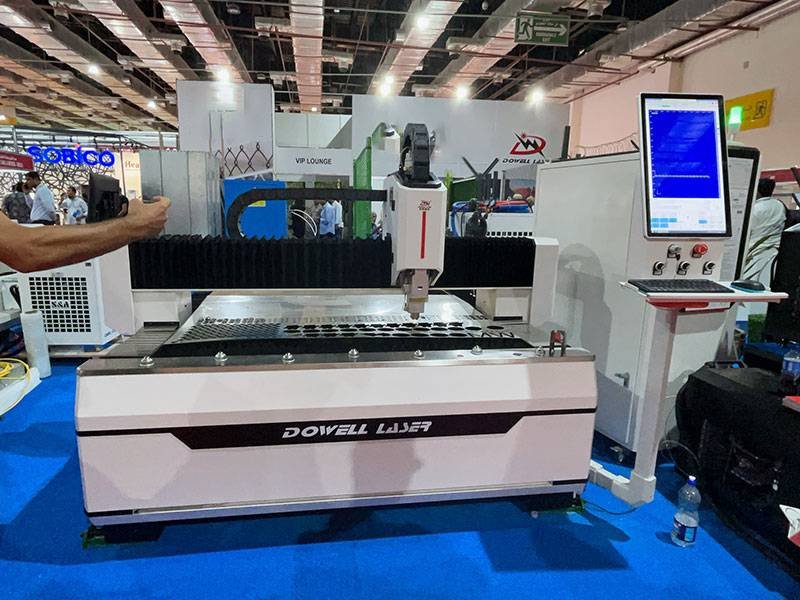

China professional cnc fiber laser cutting machine supplier manufacturer

CNC metal fiber laser cutting machine is favored by business owners because of its efficient cutting effect. Laser CNC metal cutting has become an essential metal cutting equipment for industrial manufacturing. Companies can quickly increase production capacity and save costs for you. Some laser business enthusiasts have also benefited from it. Are you also looking for a reasonable cnc fiber laser cut machine price ? This article can help you.

Core components such as lasers, laser cutting heads, motors, guide rails, racks, reducers, chillers, and CNC systems. The brand, quality, and performance of these components will also affect the price of the laser cutting machine.

Dowell Laser has 13 years of experience in laser equipment manufacturing and has rich export experience. Professional design and development personnel can meet your needs for appearance, color and size. Professional technicians provide technical training and operation instructions manuals.

DOWELL laser is the best cooperative supplier for you.

The laser cut sheet metal cost with different powers is related to the brand, power size, laser brand, cutting table, cutting material, after-sales service, etc. It generally ranges from $20,000-$300,000. The higher the power, the more expensive the price.

Types of laser cutting mainly refer to the format size and form of laser cutting machines. Different types of laser cutting machines are suitable for cutting steel plates of different specifications and shapes. Common laser cutting machine models include 3015, 4015, 4020, 6020, 6025, etc. The numbers represent the length and width of the workbench (in millimeters)

If the budget is reasonable, it is not recommended to buy a second-hand machine. If the initial funds are limited, you can consider using a 2nd hand laser cutting machine, but at the same time, you should also pay attention to the performance of the second-hand machine, and the maintenance cost is relatively high.

This depends on the material of the plate being cut, whether it is for home or commercial use, the cutting format, and the budget. Choosing the appropriate laser steel cutting machine brand

Generally, lasers produced by well-known laser manufacturers have a lifespan of up to 100,000 hours. The specific details depend on how to use and the maintenance of the laser cutting machine sheet metal .

The maximum thickness of different materials cut by the 2000W laser cutting machine: the maximum thickness of carbon steel is 16mm; the maximum thickness of stainless steel is 6mm; the maximum thickness of aluminum plate is 4mm; the maximum thickness of copper plate is 4mm;

The maximum thickness of different materials cut by the 3000W fiber laser cutting machine: the maximum thickness of carbon steel is 22mm; the maximum thickness of stainless steel is 12mm; the maximum thickness of aluminum plate is 8mm; the maximum thickness of copper plate is 8mm;

The maximum thickness of different materials cut by the 4000W fiber laser cutting machine: the maximum thickness of carbon steel is 25mm; the maximum thickness of stainless steel is 12mm; the maximum thickness of aluminum plate is 10mm; the maximum thickness of copper plate is 10mm;

The maximum thickness of different materials cut by the 6000W fiber laser cutting machine: the maximum thickness of carbon steel is 25mm; the maximum thickness of stainless steel is 20mm; the maximum thickness of aluminum plate is 16mm; the maximum thickness of copper plate is 12mm.

The 12000W laser can cut stainless steel up to 40mm, but the quality of the cutting surface above 25mm is not guaranteed, and the cutting surface below 25mm is definitely a bright surface. The cutting capacity of 15000W will be better, but the price is also higher.

Consult us for the latest quotes and equipment product catalogs

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.