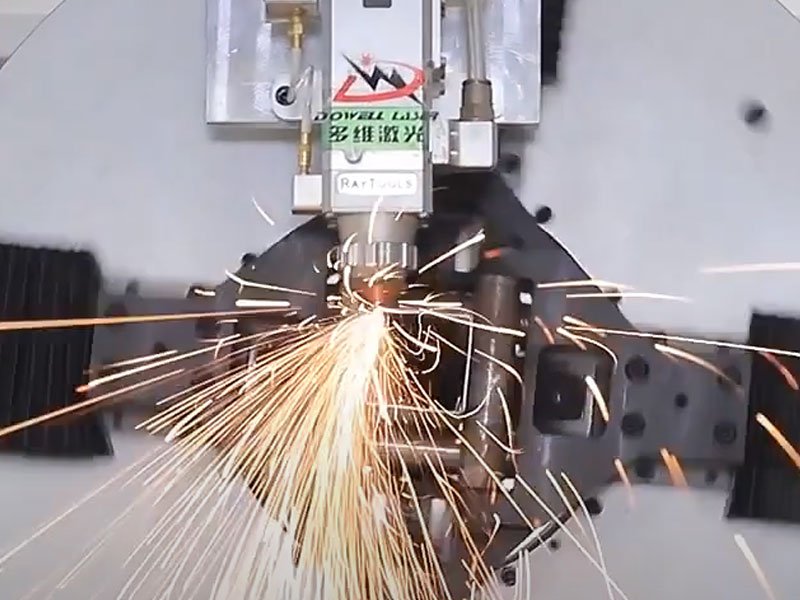

The advent of fiber laser cutting machines has led to the rapid development of the sheet metal industry, cnc laser cutter for metal cutting performance: efficient, clean, quiet, reliable, safe, energy-saving.

Do you want to understand the difference between laser cutter vs cnc ? I hope this article library can help you. Read the following article quickly.

What is a CNC laser cutter for metal

The cnc fiber laser cutter is a very precise laser equipment, which mainly relies on the high-energy heat generated by the laser to cut the substrate. Fast cutting speed, high precision, saving labor and improving work efficiency.

What is a CNC machine

The CNC punching machine is a cutting machine controlled by the operating system, which has been greatly improved compared with the traditional cutting method, and the price is relatively cheap. Just input the drawings you want to cut into the computer and you can cut efficiently.

How does a cnc laser cutter work

Composition of cnc machine vs laser cutter

Laser cnc metal cutter composition:Fiber laser, laser cutting head, water cooler, CNC operating system, laser cutting software, laser cutting bed, servo motor

CNC cutting machine tools are mainly composed of machine tools, CNC systems, and nesting software.

Advantage of CNC plasma cutting machine vs laser cutter

Advantage of laser cutter

- Metal cutting is favored by people in the market because of its fast cutting speed, high precision and no need for secondary grinding;

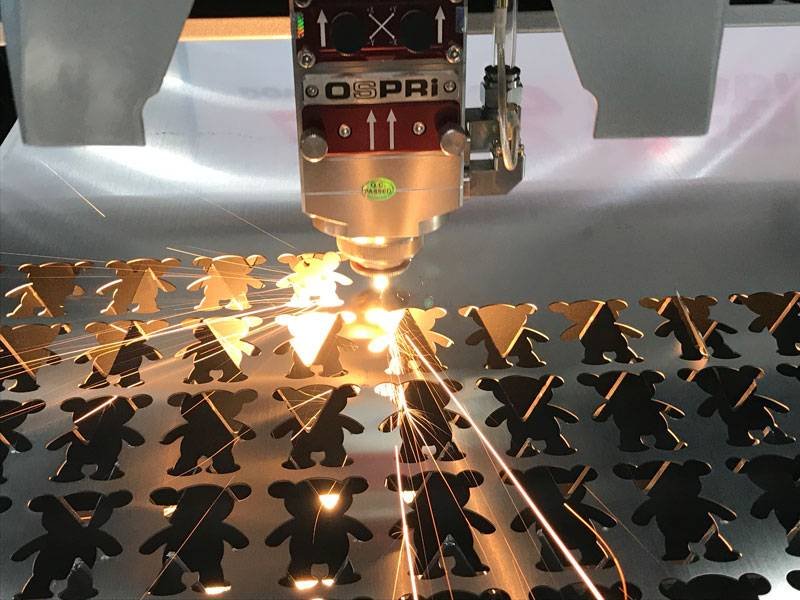

- You only need to input any graphics to be cut into the computer, and then you can cut without graphics restrictions;

- The thermal deformation is small during cutting, and there will be no dross, which reduces the process and improves the production capacity;

- Diversity of cutting materials, as long as it is metal sheet, it can be cut;

- The operation is simple, only need training to get started;

- It can realize nesting cutting, improve work efficiency and reduce production cost

Advantage of CNC plasma cutting machine

Plasma cutting and fine plasma cutting are similar to flame cutting, the heat-affected zone is too large, but the precision is much higher than flame cutting, and the speed also has an order of magnitude leap, becoming the main force of medium plate processing.

The upper limit of the actual cutting accuracy of China’s top CNC fine plasma cutting machine has reached the lower limit of laser cutting. When cutting 22mm carbon steel plate, it has reached a speed of more than 2 meters per minute, and the cutting end surface is smooth and flat, and the slope is the best. Control within 1.5 degrees.

The disadvantage is that the thermal deformation is too large when cutting thin steel plates, and the slope is also large. It is powerless when the precision is high, and the consumables are relatively expensive.

4 Difference between cnc vs laser cutter

CNC vs laser cutter cost

Traditional numerical control equipment has cumbersome procedures, requires a lot of manpower, and costs relatively high.

3kw laser cutting machine cost: power and consumables (the consumables of the laser cutting machine include focusing mirror, ceramic body, nozzle, reflector, gas, etc.;

Punch consumables: mold, labor and equipment depreciation.

Cutting accuracy

Laser cutting does not need to touch the plate, only needs to align the focus to perform efficient cutting, the cutting surface is smooth, there is no dross, the positioning accuracy is 0.03mm, and the workpiece accuracy can reach 0.1mm.

The processing precision of CNC punching machine is weaker than that of laser cutting. There are burrs that need secondary grinding, and the workpiece is easy to deform.

Laser cutting material:

Laser cutting stainless steel can cut a variety of metal materials, such as: carbon steel, brass, stainless steel, aluminum plate, non-ferrous metals, etc. The power can reach up to 30kw, and the thickest can cut 50mm carbon steel.

CO2 laser cutting machine can cut acrylic, glass, leather, cloth and other materials.

CNC equipment can only stamp metal materials, and the thickness is limited to less than 6mm.

Flexibility

The metal laser cutting machine can cut any graphics, and can also punch holes, mark and lettering.

CNC punching machines can only punch holes, and holes with special shapes are not acceptable. Different molds need to be replaced, which is cumbersome and labor-intensive.

For different processing requirements, CNC punching machines need to replace different molds, which is relatively expensive and not very cost-effective.

Conclusion:

There are many laser cutting equipment exporters in the market. If you want to find the best cnc fiber laser cutter factory, you need to compare several prices, after-sales service, production capacity, service ability, delivery speed, etc. There are many cnc laser cutter manufacturers in China. If you want to pick up a specific CNC laser cutter manufacturer, you can visit the manufacturer to see the specific situation.