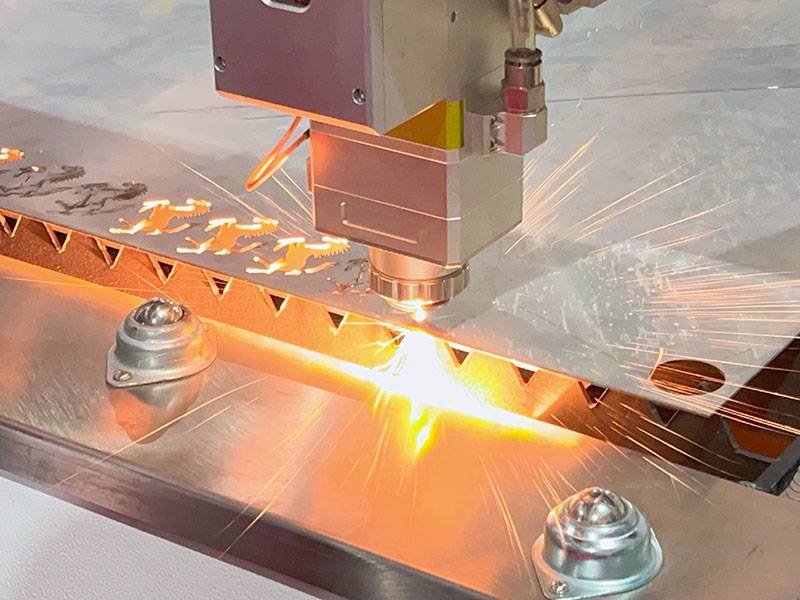

Laser cutting is a high-precision and efficient industrial sheet cutting equipment that uses the high-energy heat generated by the laser beam to melt or vaporize the metal sheet to achieve laser cut accuracy tolerances.

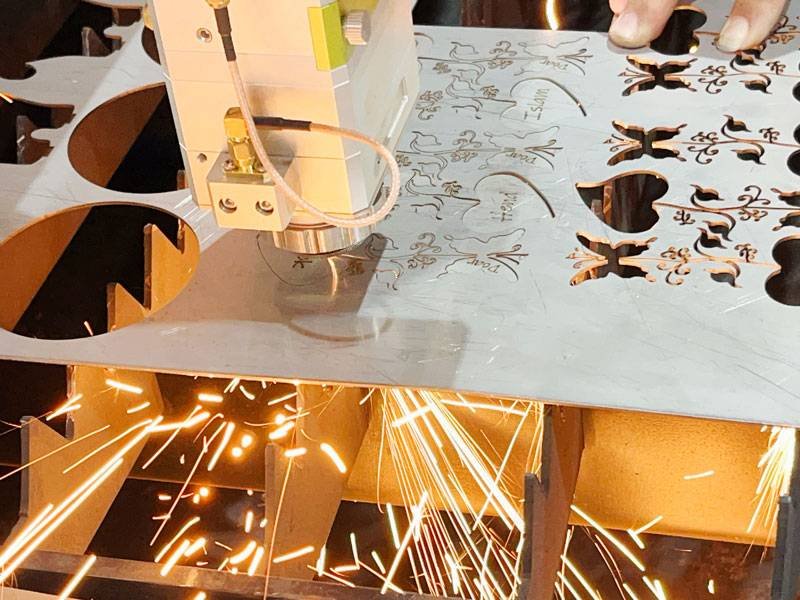

Precision laser cutting is widely used in metals, non-metals, plastics, ceramics and other materials. It can be used in automobile production, aviation, precision electronics, metal processing, construction industry, elevator manufacturing, kitchen utensils and other fields. Laser cutter accuracy is not affected by patterns, Shape restrictions.

What is the laser cutting accuracy tolerance error?

The processing accuracy of laser cutting machines is currently the main standard parameter used to measure the quality of machine tools in the industry. Among them, the processing accuracy of laser cutting machine tools is mostly within the error range of 0.5MM. Of course, there are a few manufacturers that provide processing accuracy that can reach 0.3MM error. High precision laser cutter tools, but generally speaking, there are still certain processing scale tolerances in cutting accuracy.

Factors That Affect Laser Cutting Accuracy

Cutting material type: The type of cutting material has a great influence on the accuracy. The performance of the material, the smoothness of the surface, etc. are all different for laser reflectivity, thermal conductivity, etc.

Thickness of the material: The thicker the material, the greater the power required and the slower the cutting speed. For thin plates, the cutting accuracy is better.

Laser power: The higher the power, the higher the precision, and the smaller the laser cutter tolerance.

Cutting speed: The speed at which the laser beam passes through the material affects accuracy. Finding the optimal cutting speed for a specific material is critical.

Auxiliary gas type: The setting of auxiliary gas pressure can blow away the slag after cutting and improve the accuracy.

Control system: The operator inputs instructions into the system, and the precision cutting control system will be specially optimized for stability, anti-interference, motion algorithm, precision control and other aspects.

Focused spot size: The smaller the spot after the laser beam is focused, the higher the cutting accuracy, especially the smaller slit, the smallest spot can reach 0.01mm.

Workbench positioning accuracy: The higher the workbench accuracy, the higher the cutting accuracy.

Setting the focus: Precise cutting requires a well-focused, high-quality laser beam. Factors such as beam divergence and mode shape affect accuracy.

What is laser cutting tolerance standard

The tolerance standards for laser cutting are generally determined based on the different materials being processed and specific requirements. The following are common standards:

- Dimensional tolerance: Generally ± 0.1mm, but higher precision requirements can reach around ± 0.01mm.

- Straightness tolerance: Within the same cutting piece, the straightness tolerance is generally within 0.2mm, with higher requirements It can reach within 0.05mm.

- Verticality tolerance: For vertical cutting, the verticality requirement should be within ± 0.05mm, or even 0.01mm within.

- Tolerance between parts: According to manufacturing requirements and processing forms, the tolerance between parts is generally between 0.1~0.5mm between.

- Surface smoothness tolerance: Laser cutting generally achieves a high surface smoothness of Ra, which can reach 0.1 μ M Left right.

It should be noted that the tolerance standard for laser cutting not only depends on the accuracy of the cutting machine, but also on the material itself.

The physical properties, cutting method, and subsequent processing technology are related. Therefore, when making precision parts, it is important to develop corresponding tolerance standards based on specific circumstances to ensure part quality and production efficiency.

How to Eliminate Laser Cutting Precision Tolerances

You can first consider using radius compensation to compensate for the impact of cutting tolerances. Program and execute on the laser cutting machine control system according to the basic size. Calculate and program according to the basic size of the part. Use the same turning tool to process the outer circle everywhere, but when processing different tolerances For dimensions with position, different tool radius compensation values are used.

With this method, you must first know the radius of the tool tip arc (the machining trajectory of this part is parallel to the X-axis and Z-axis, so it is not necessary to know the radius of the tool tip arc), so it is inconvenient to use and can only be applied to some CNC systems.

If the size of the cutting part can be appropriately modified according to the drawing requirements in the early stage of cutting to eliminate the influence of the tolerance zone, it is also feasible. The specific idea is to change the basic size and the position of the tolerance zone; in terms of execution, on the premise of ensuring that the limit size of the part remains unchanged, Adjust basic dimensions and tolerance zone positions.

Generally adjusted according to the symmetrical tolerance zone, the adjusted basic dimensions and tolerances. When programming, proceed according to the adjusted basic size. In this way, the same turning tool and the same tool compensation value can be used during finishing (in this example, the machining trajectory is parallel to the X-axis and Z-axis, and no tool compensation is required) to ensure machining accuracy. Of course, if the part needs to be finished (such as fine grinding) in the end, in order to ensure sufficient grinding allowance, the basic size can also be slightly larger (in this case, the tolerance zone will be asymmetrical).

Contact DOWELL LASER for laser cutting services

DOWELL LASER has focused on the production and research and development of laser equipment for 13 years and provides you with professional laser cutting equipment. We have rich production and manufacturing experience and can deliver quickly. Professional technicians provide technical training to save you costs. We can provide you with The most competitive price on the market. If you have any questions about your laser cutting project or to request a quote, contact us today.