Many customers want to make a comparison before purchasing a laser cutter machine, but after buying it home, there are problems during use. Are you looking for fiber laser cutting problems and solutions? This laser cutting troubleshooting hopes to be helpful to you.

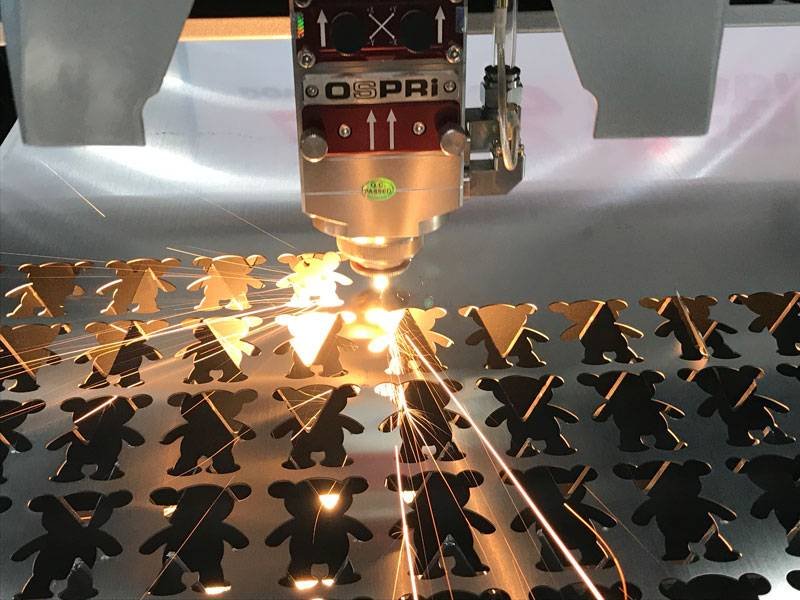

The fiber laser cutting uses the high-energy heat generated by the laser to quickly melt or vaporize the plate to be cut, then form a small hole and then cut the plate.

Whether you are an experienced metal cutting laser user or a guide new to laser cutting, this article hopes to help you quickly solve laser cut quality troubleshooting.

2 Types of CNC laser cutter perforation:

Pulse perforation

A small amount of material is melted or vaporized by a pulsed laser with high peak power. Air or nitrogen is often used as an auxiliary gas to reduce hole expansion due to exothermic oxidation. The gas pressure is lower than the oxygen pressure during cutting. Each pulse laser only produces small jets of particles, which go deeper gradually, so it takes a few seconds to perforate a thick plate.

Once the perforation is complete, immediately switch the assist gas to oxygen for cutting. In this way, the diameter of the perforation is smaller, and the perforation quality is better than that of blasting perforation. The laser used for this purpose should not only have high output power; more importantly, the time and space characteristics of the beam, in addition, the pulse perforation also needs a more reliable gas circuit control system to realize the switching of gas types, gas pressure and Control of piercing time.

Blasting perforation

After the material is irradiated by a continuous laser, a pit is formed in the center, and then the molten material is quickly removed by the oxygen flow coaxial with the laser beam to form a hole. Generally, the size of the hole is related to the thickness of the plate. The average diameter of the blasting perforation is half of the thickness of the plate.

Therefore, the diameter of the blasting perforation on a thicker plate is larger and not round. It is not suitable for use on parts that require high processing accuracy. on waste. In addition, because the oxygen pressure used for perforation is the same as that for cutting, the splash is larger.

Fiber laser cutting stainless steel problems

Laser cut stainless steel with burrs

When the above situation occurs, first consider the burrs when cutting low-carbon steel, but the cutting speed cannot be simply increased, because sometimes the plate will not be cut through when the speed is increased. This situation is especially prominent when processing aluminum-zinc coated plates. At this time, other factors of the machine tool should be considered comprehensively to solve it, such as whether the nozzle needs to be replaced or not, and the movement of the guide rail is unstable.

Fiber laser cutting stainless steel surface rust

The rusted stainless steel has a great impact on the cutting effect. The rust will cause the laser light source to reflect back on the nozzle, causing damage, even damage to the components, and in severe cases, it will cause an explosion.

When fiber laser cutting stainless steel, do a good job of derusting.

Stainless steel surface coating

When cutting brushed or mirror stainless steel, use film cutting technology, and the film-coated side will be cut first.

Painted stainless steel surface

The paint contains toxic substances, which will produce toxic smoke when cutting, which will be harmful to the human body. So, when painting stainless steel with a laser cutter, wipe off the surface paint.

Laser cutting aluminum problems

Cutting aluminum is a laser cutting issue, mainly because aluminum is a highly reflective material and has a low absorption rate for laser light.

What gas is used for laser cutting aluminum

The auxiliary gases that can be used by laser cutting machines are mainly oxygen, nitrogen, air and argon.

- It is recommended to use nitrogen when laser cutting aluminum. Nitrogen can prevent oxidation well and retain the characteristics of the material itself. Nitrogen is a better choice;

- When laser cutting stainless steel, we should choose high-purity nitrogen. Nitrogen prevents oxidation of the cut so that the cut does not turn black.

- High-purity oxygen should be used for laser cutting carbon steel plates. The combustion-supporting effect of oxygen accelerates the workpiece speed.

What is the laser cutting aluminum thickness?

3000W laser cutting aluminum material below 8mm, 6000W laser cutting aluminum material below 16mm, 10000W laser cutting aluminum material below 20mm.

Analysis on the Deformation of Small Holes in Cutting Process

This is because the machine tool does not adopt the method of blasting perforation when processing small holes, but uses the method of pulse perforation, which makes the laser energy too concentrated in a small area, and burns the non-processing area, resulting in deformation of the hole. affect the processing quality.

At this time, we should change the pulse perforation method to the blasting perforation method in the processing program to solve it. For the laser cutting machine with lower power, it is just the opposite. When processing small holes, pulse perforation should be used to obtain better surface finish.

Normal sparks when cutting mild steel

This situation will affect the quality of the cut section finish of the part. At this time, when other parameters are normal, the following situations should be considered: the loss of the nozzle NOZZEL of the laser head, and the nozzle should be replaced in time. If there is no new nozzle to replace, the pressure of the cutting working gas should be increased; the thread at the connection between the nozzle and the laser head is loose.

At this time, the cutting should be suspended immediately, check the connection status of the laser head, and re-install the thread.

Burrs appear in laser cutting mild steel

According to the working and design principles of laser cutting, the following reasons are analyzed and concluded to be the main reasons for the burrs on the workpiece: the upper and lower positions of the laser focus are incorrect, and the focus position test needs to be done, and adjustments are made according to the offset of the focus; If the output power of the laser generator is not enough, it is necessary to check whether the laser generator is working normally.

If it is normal, observe whether the output value of the laser control button is correct and adjust it; the cutting line speed is too slow, and it is necessary to increase the line speed during operation control; The purity of the gas is not enough, and it is necessary to provide high-quality cutting working gas; the focus position of the laser is shifted, and the focus position test is required, and adjustments are made according to the offset of the focus; the instability caused by the long running time of the machine tool needs to be Shut down and restart.

Analysis of Laser Incompletely Cut Through State

After the analysis, it can be found that the following situations are the main causes of unstable processing: the selection of the laser head nozzle does not match the thickness of the processed plate; the laser cutting line speed is too fast, and the operation control is required to reduce the line speed; If the error of the laser focus position is too large, it is necessary to re-check the sensor data of the nozzle, especially when cutting aluminum.

Fiber laser troubleshooting:laser alarm

- Check the laser fault:

Check whether the laser is faulty, the laser beam transmission path is blocked, the output power is unstable, etc.

- Check the laser output environment:

The laser output environment, the cleanliness of the focusing lens, and whether the control system is normal.

- Check the power supply:

Such as power failure or unstable electrical voltage

- Laser manual:

Check the laser cutting problems and solutions pdf, check the cause and solve it, or contact the laser manufacturer for help.

It should be noted that lasers have high technical and skill requirements for maintenance personnel. When performing maintenance, operate in accordance with the laser cut quality guide, and take safety protection measures to ensure safety and normal operation of the equipment.

Laser light not working problems and solutions

1.Is the tungsten filament in the lamp damaged?

When the light does not light up, the first thing to check is whether the tungsten filament in the lamp is burned out. Just replace it with a new tungsten filament.

2.Circuit breaker is open

You need to use an electric pen to check whether the circuit breaker can be energized normally. If something goes wrong, it needs to be replaced immediately.

3.Is the fuse of the switch burned out?

If there is no problem with the circuit breaker, then you can check whether the switch’s fuse is burned out. If the switch’s fuse blows, you will need to replace it with a new fuse.

4.Wiring problem

If the switch’s fuse is also intact, you need to check the wiring. Check if there is an open circuit in the wiring, causing the light to not light up.

Laser cutter not cutting through problem

- Laser power drops

- The plate is too thick and exceeds the cutting limit of the equipment.

- Contamination of optical components

- Equipment light spot debugging is not up to standard

- Equipment cutting speed is too fast

- Insufficient auxiliary gas pressure

The Solution to laser cutting failure:

- Check whether the power of the laser cutting machine has dropped. If so, replace it with a larger voltage regulator to increase the current output power.

- Reduce the cutting speed when cutting, clean the contaminated reflector, and replace the focusing lens.

- If the light path is incorrect, readjust the light path and adjust the focus until the laser produces a round spot on the paper.

- When cutting copper and aluminum, polish the surface in advance or apply light-absorbing material to deal with the problem of high reflectivity.

- Regularly clean foreign matter in the nozzle, increase the auxiliary gas pressure, and replace the distilled water in the cooling system in a timely manner.