What is a laser tube cutting machine?

The laser tube cutting machine uses the high-energy heat generated by the fiber laser to cut, punch, and mark metal pipes such as round pipes, square pipes, and rectangular pipes through the pipe numerical control cutting system.

Metal Laser Tube Cutting features:

- High cutting precision, fast efficiency, reducing the loss of consumables;

- The thermal deformation is small during cutting, the cutting surface is clean and smooth, and there will be no dross, which is very convenient for later welding work;

- It can realize mass production, save labor and improve work efficiency;

Application :

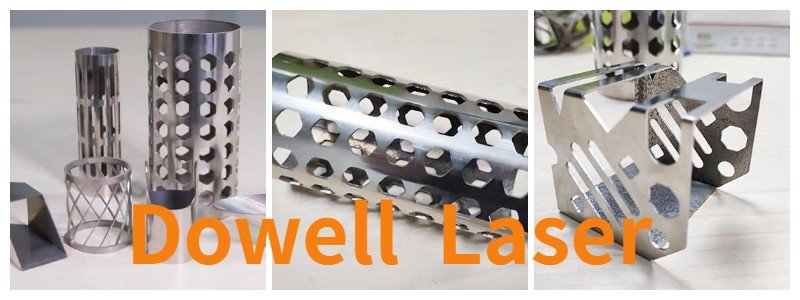

The tube laser cutting machine can realize the processing, drilling and cutting of any shape on the metal tube. And it can also be equipped with automatic loading, unloading and feeding. The cutting precision is high and the speed is fast.

The use of laser pipe cutting machines is very extensive in our daily life, including fitness industry, hardware furniture accessories, staircase industry, automobile anti-theft net, guardrail and so on. These industries have already used pipe laser cutting machines.

The laser tube cutting machine has a variety of functions, can perform bevel cutting, and is fast.. Compared with the ordinary automatic pipe cutting machine, it not only improves the production efficiency, but also can cut various angles. In addition, the industrial laser pipe cutting machine is powerful, not only cutting, but also cutting bevel ports, hollowing out holes and so on. The cut is smooth and the seam is small, which effectively reduces material loss.

With the development of laser pipe cutting machines, more and more versatile laser pipe cutting machines have been developed. For the production of products, the use of a fully automatic laser pipe cutting machine can improve the competitiveness of the products and achieve the growth of enterprise benefits.

3.What is the operating process of the laser pipe cutting machine?

At present, the laser pipe cutting machine is generally operated on a numerical control system. Especially the fiber laser pipe cutting machine, professional computer-aided program to complete the CNC program. Numerical control programming is all done on the computer, if there are some simple processing procedures, it can be done on the numerical control system.

Then it is generally recommended not to program data on the numerical control technology, because this will take up a lot of machine tool usage time, and it will also take a long time for programmers. And it is impossible to program and layout some complex parts with complex shapes.

When the laser pipe cutting machine is processed, it will have an advance test. In this test stage, the operator can observe the processing situation and make timely adjustments. If it is a large-scale operation and processing, an abnormality is found during the operation. If so, you can stop the machine in time to check in parallel to eliminate unsafe factors.

With the in-depth study of laser cutting technology. Laser equipment is becoming more and more extensive in daily production. The use of laser pipe cutting machines not only brings convenience to people’s work but also brings greater economic benefits to enterprises.

Maintenance of laser pipe cutting machine

Nowadays, many How to make the laser tube cutting machine last longer is an important issue for some business owners.

Because the cost of purchasing a laser pipe cutting machine is relatively high, how to maintain the laser pipe cutting machine is a more important thing.

- Before starting to use, check the user manual, the operation process, whether the components of the machine are on track, and ensure the normal operation of the machine to prevent failures

- Usually pay attention to the cleaning of the equipment, and the laser cutting lens should not have dust

- Whether the lubricating oil of the equipment is replaced in time

- When the equipment fails, stop working immediately and deal with it in time