The advent of the section steel laser cutting machine has replaced the traditional manual and semi-automatic blanking methods, which improves the work efficiency and reduces labor costs. It reduces the problem of wide slits and waste of materials in plasma cutting machines.

One-stop efficient solution for cutting, locking, beveling, marking and marking.The equipment adopts three-dimensional six-axis five-linkage technology, which can realize 45-degree bevel cutting.

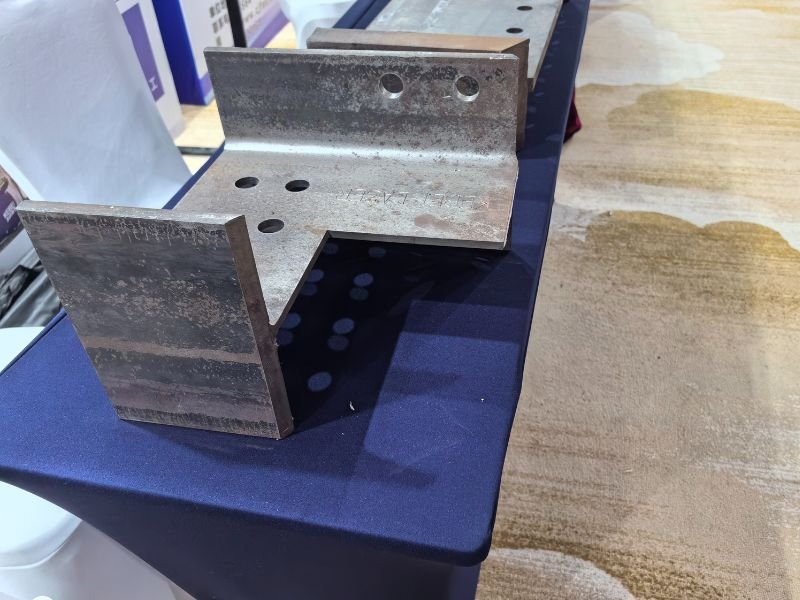

H channel laser cutting machine is a laser cutting equipment specially for channel steel, angle steel, I-beam, H-beam, L-beam cutting. Cutting, punching, marking, scribing, bevel cutting, etc. can be performed on the workpiece.

Laser cutting for H-shaped profiles can achieve micron-level cutting accuracy, ensuring smooth and burr-free cutting edges. This is particularly important for H-shaped steel components that require strict tolerance control, such as in the manufacture of precision structural parts in the fields of construction, bridges and ships, to ensure that the dimensions of each component are accurate.

Laser cutting for structural H beams can easily cope with steel materials of different shapes and specifications, including standard steel and special-shaped steel. Whether it is straight cutting, curve cutting, or complex geometric cutting, Laser cutting technology for steel beams can be completed flexibly and efficiently.

High-strength steel beam laser cutter can process a variety of metal materials, including carbon steel, stainless steel, aluminum alloy, etc., to meet the processing needs of different steel materials. This wide adaptability allows Laser cutter for industrial steel projects to play a role in a variety of industries.

Compared with traditional mechanical cutting, Precision cutting for industrial steel is fast, can significantly improve production efficiency and shorten production cycle. This Structural laser cutting efficiency is particularly suitable for mass production needs, while the high degree of automation reduces manual intervention, thereby reducing labor costs.

Metalworking laser technology is a non-contact processing method that produces less waste and relatively low energy consumption. Since the heat-affected zone during Sheet metal laser cutting is small, it is conducive to the reuse of materials and conforms to the concept of modern green manufacturing.

Laser cutting technology for steel beams usually requires no or only little subsequent processing, such as grinding and trimming, which further saves time and cost. By completing processes such as bevel cutting and punching in one go, it facilitates subsequent welding.

Laser machine for structural beams fabrications are often integrated into automated production lines, working together with assembly welding equipment, handling robots, etc., to form an unmanned operation process from unloading, cutting to welding. This greatly improves production efficiency and reduces labor costs.

By replacing traditional manual marking, drilling, cutting and other processes, Steel profile and H beam laser machine reduce material waste and shorten processing cycles, thereby significantly reducing the production costs of enterprises in the long run.

Industrial laser cutter for H profiles is a laser cutting equipment specially designed for cutting channel steel, angle steel, I-beam, H-shaped steel, and L-shaped steel. The workpiece can be cut, punched, marked, scribed, beveled, etc.

The Beam laser cutting machine is mainly used for cutting and bending steel pipes, connecting steel pipes and steel plates, assembling and assembling steel components. In addition, it can achieve high-precision and high-efficiency manufacturing processes in shipbuilding, improving the quality and performance of ships. .

The cutting and processing of steel in industrial equipment manufacturing can meet the needs of various industries for industrial equipment.

Structural steel laser machine is mainly used to manufacture building frames and structural components. Through laser cutting, H-beams, I-beams and other profiles can be processed quickly and accurately to meet the complex requirements of architectural design. Laser cutting technology not only improves production efficiency, but also reduces material waste, ensures the quality of cutting edges, and makes subsequent welding and assembly processes smoother.

The flexibility of laser cutting machines allows designers to achieve more complex geometric shapes, providing more possibilities for modern architecture.

Widely used in the processing of hulls and superstructures. Shipbuilding is mainly based on steel plate raw materials. Laser cutting can replace traditional punching processing methods, greatly shortening the production cycle and reducing costs.

Hull plate: Steel frame laser cutter can effectively process marine steel plates of various thicknesses, ensuring good cut quality and strong verticality without secondary processing.

Structural components: Internal structures such as ribs, frames and bulkheads are ensured by heavy industry laser cutting to ensure precise size and fit, thereby maintaining the strength and stability of the ship.

Deck construction: The deck is composed of a large number of complex components. Metalworking laser technology can provide high-precision cutting, reduce coordination time, and improve the overall assembly quality.

Heavy-duty H beam laser cutter technology is widely used in the manufacturing of wind and solar energy equipment. By efficiently and accurately processing various metal components, lighter and stronger equipment can be produced, improving the overall performance of energy equipment. H beam metal cutting solutions is also suitable for metal parts processing in power equipment.

H profile laser cutter is used for the processing of body frames, chassis and other important parts. Auto parts have high requirements for precision and strength. Precision cutting for industrial steel technology can achieve extremely high processing accuracy, ensuring that each part fits perfectly during assembly. Laser cutting can also reduce material waste, improve production efficiency, and thus reduce production costs.

Profile specification 340*250 (maximum cutting 3500MM, single-sided and double-sided bevel cutting, welding holes, web special-shaped cutting.

Laser machine for H-beam steel is mainly used to cut various metal materials, including carbon steel, stainless steel, aluminum alloy, etc. Its flexibility enables it to meet different industrial needs.

Metal beam laser cutting technology is a non-contact processing method that produces less waste and relatively low noise, which is more in line with modern environmental protection requirements. However, harmful gases may be generated during operation, so a good ventilation system is required.

Yes, although the basic operation is relatively simple, in order to ensure safety and equipment performance, it is recommended that operators receive professional training to master equipment usage skills and maintenance knowledge.

Operating costs mainly include energy consumption, maintenance costs and consumables (such as gas). Despite the higher initial investment, its high efficiency and low scrap rate usually bring better long-term economic benefits.

Common problems include poor cutting quality or slow speed. It is recommended to check parameters such as laser power, focus position, nozzle distance, and adjust them according to the equipment manual. If the problem persists, it is recommended to contact professional technical support.

The service life usually depends on maintenance and frequency of use. A well-maintained device can be used for many years, but some parts (such as the laser) may need to be replaced regularly.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.