In modern manufacturing, fiber laser cutting machines are widely popular due to their high efficiency, precision and flexibility. Many companies tend to overlook the importance of their service life when investing in such equipment. Understanding the service life of fiber laser cutting machines and the factors that affect them can not only help improve production efficiency, but also reduce long-term operating costs.

This article will take a deep look at the service life of fiber laser cutting machines and strategies for extending their service life.

Working principle of fiber laser cutting machine

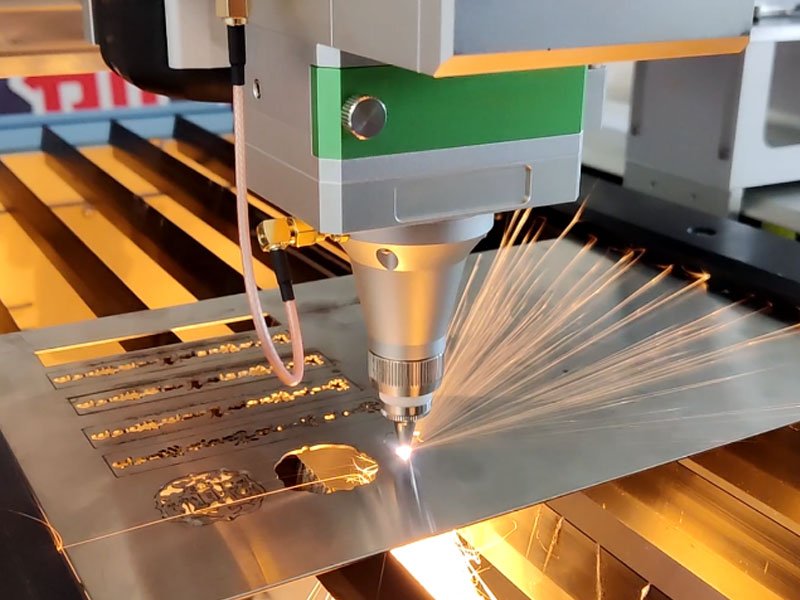

Fiber laser cutting machine uses high-energy laser beam to cut materials. The laser is transmitted through optical fiber and focused on the surface of the material, generating high temperature instantly, melting or vaporizing the material. Due to its high cutting accuracy and small heat-affected zone, fiber laser cutting machine has been widely used in the metal processing industry.

What is the lifespan of laser cutting machine?

The service life of a fiber laser cutting machine is generally considered to be up to 100,000 hours. This figure is based on the performance and design of the laser and reflects its expected operating time under normal operating conditions. If it is operated 8 hours a day, this means that a fiber laser cutting machine can theoretically be used for more than 33 years

Fiber laser cutting machine life and material type

- Absorption rate of materials

Different materials have different absorption capacity for laser beams. The short-wavelength beams produced by fiber lasers are more easily absorbed by metals, so they show higher electro-optical conversion efficiency and more stable cutting performance when cutting metals such as stainless steel, carbon steel and aluminum alloys. If the reflectivity of the cutting material is high (such as aluminum and copper), it may cause part of the laser energy to be reflected, which will affect the cutting effect and may increase the burden on the laser and shorten its life.

- Material thickness

Cutting materials of different thicknesses has different requirements for laser power and cutting speed. Thicker materials require higher laser power to cut effectively, which may cause the laser to work under high load, thereby accelerating wear. When processing thick metal plates, fiber laser cutting machines may need to adjust power and speed to ensure cutting quality and avoid excessive wear.

- Thermal conductivity

The thermal conductivity of the material will also affect the efficiency of laser cutting. High thermal conductivity materials (such as aluminum) will quickly conduct heat away, which may cause the energy density of the laser focus point to decrease, requiring adjustment of laser parameters to maintain effective cutting. For metals with low thermal conductivity (such as stainless steel), it is easier to achieve efficient cutting because heat is not easily diffused.

- Cutting speed and power

The type of material also affects the optimal cutting speed and required power. Properly increasing the cutting speed can reduce heat input and obtain better cutting edge quality, but too fast speed may result in incomplete cutting or failure to penetrate the material.

How to judge the life of laser cutting machine

- Laser life

Fiber laser cutting machine lasers usually have a long lifespan, theoretically up to 100,000 hours. However, the actual lifespan may be affected by a variety of factors, such as operating frequency and maintenance. Regularly recording the operating time of the laser can help determine its remaining lifespan.

- Signs of performance degradation

- Over time, laser cutting machines may show signs of performance degradation, including:

Decrease in cutting accuracy: If you find that the cutting edge is no longer neat, or the cutting depth is uneven, it may be a sign of equipment aging. - Power reduction: Reduced laser output power will cause slower cutting speeds, and settings need to be adjusted to compensate for insufficient power.

- Increased failure frequency: Old equipment may frequently fail or require repairs, affecting production efficiency.

- Maintenance and servicing records

- Cooling system: Keep the cooling system in normal operation to prevent overheating.

- Optical components: Clean the lenses and lenses regularly to ensure the quality of the laser beam.

- Mechanical components: Check the wear of components such as guides and nozzles.

- Operating environment

The environment in which the equipment is located has an important impact on its life. Ensure that the working environment is dry, well ventilated, and free of dust and high temperature, which can effectively extend the service life of the equipment.

- Professional inspection and calibration

Invite professionals to inspect and calibrate the equipment regularly to ensure that all parameters are normal. This includes the alignment of the laser head, the stability of power output, etc. If any abnormality is found, it should be handled in time to avoid greater losses.

Factors affecting the fiber laser cutting machine lifespan

Equipment quality

High-quality laser cutting machines are usually made of high-quality materials and advanced technology, and their service life is relatively long. Choosing well-known brands and certified equipment can effectively reduce the failure rate.

Daily maintenance

Regular maintenance and care are important factors in extending the service life of equipment. Regular inspection of lasers, cooling systems and mechanical parts, and timely replacement of worn parts can ensure that the equipment is always in the best condition.

Operating environment

Fiber laser cutting machines have certain requirements for environmental conditions. Excessive or low temperature, humidity and dust pollution may affect the performance and life of the equipment. Therefore, it is crucial to maintain a clean and suitable working environment.

Operating habits

The skill level and operating habits of the operator directly affect the service life of the equipment. Professionally trained operators can better grasp the performance of the equipment and reduce damage caused by misoperation.

Load and frequency of use

Excessive load or frequent use will accelerate the wear of the equipment. Reasonable production plan and avoid long-term high-intensity operation will help extend the life of the equipment.

How to extend the service life of fiber laser cutting machine

Develop a maintenance plan

Establish a detailed maintenance plan, including regular inspections and maintenance, to ensure the normal operation of each component.

Train operators

Systematically train operators to master the correct operation methods and maintenance knowledge, thereby reducing human errors.

Optimize workflow

By rationally arranging production processes, avoiding unnecessary downtime and overload, improving work efficiency and protecting equipment.

Monitoring equipment status

Using a monitoring system to track equipment status in real time, timely discover potential problems and deal with them, can effectively reduce the occurrence of failures.

Summarize

As an important tool in modern manufacturing industry, the service life of fiber laser cutting machine directly affects the production efficiency and cost control of enterprises. By understanding the influencing factors and taking appropriate measures, the service life of the equipment can be significantly extended, thereby bringing greater economic benefits to the enterprise. When selecting and using fiber laser cutting machines, companies should pay attention to maintenance and management to achieve long-term and stable production capacity.