The 1500 air cooled welding machine is based on independent property rights of air-cooled 976nm high-efficiency energy-saving technology, high-brightness single-module laser technology, and embedded laser welding process software. It is China’s first kilowatt-class air cooled laser welding machine.

Air-cooled portable laser welder advantages:

1.Simple operation, no welder certificate required

Traditional welders need a lot of training and research. The control device of the air-cooled laser welding machine is intuitive and concise. The machine is factory preset with commonly used welding parameters, and users can customize and save the required processing parameters.

2.Efficient welding, saving labor costs

The efficiency of air-cooled hand held laser welding is 2-10 times that of traditional manual arc welding, and it can save at least 2 labor costs a year. There is almost no need for polishing and cleaning after laser welding, which can save labor costs.

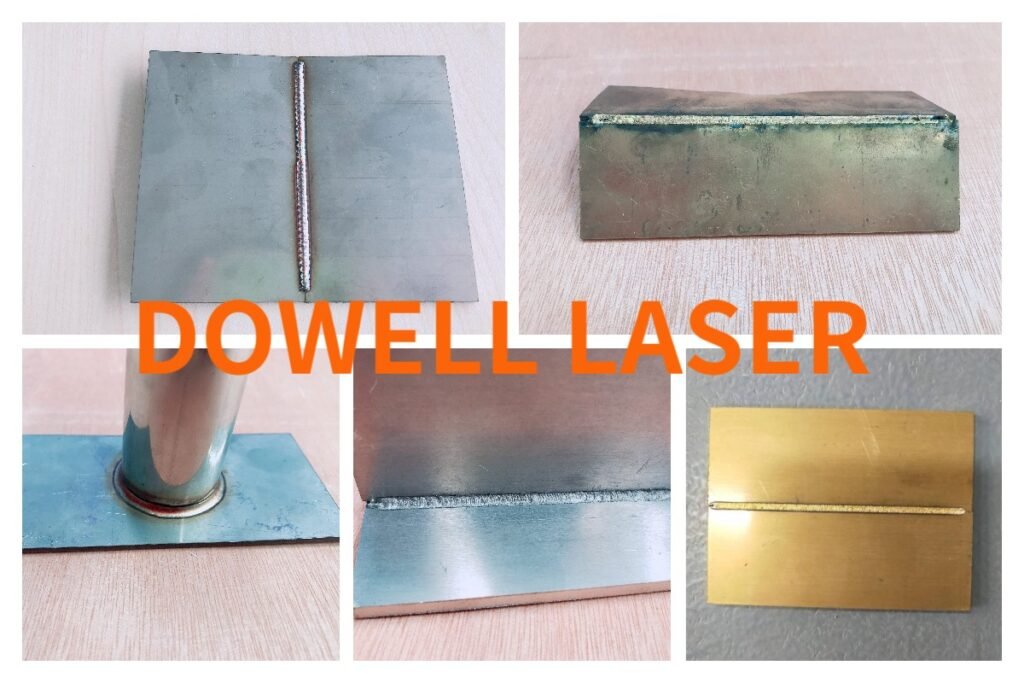

3.The welding seam is beautiful, no deformation, no need for follow-up treatment

The air-cooled laser welder can weld common steels (such as carbon steel, stainless steel, galvanized steel, etc.), aluminum alloys, and brass. The welding seam is beautiful, no deformation, no deformation of the weldment, no need for follow-up treatment. Welding steel, penetration depth up to 4mm; welding aluminum alloy/brass, penetration depth up to 3mm.

Features of air cooled laser welder:

- The output power is 1KW, and the welding penetration reaches 3mm

- Based on 976nm pump technology, high electro-optical conversion efficiency ≥42%

- Single pendulum welding head with adjustable welding width

- The weight of the whole machine is less than 60kg, compact design, small volume

- Unique air-cooled design, low power consumption, energy saving and environmental protection, power supply 220VAC-16A

- Triple protection design, built-in air pressure detection device

You can also request a quotation for our dowell laser machine by:

Mob/Whatsapp: 0086-18654506392