Metal laser cutting machines are widely used in the industrial manufacturing industry, but most customers don’t know how to choose fiber optic laser cutting machines? How to buy best laser cutter AND engraver for small business ? Now this article will tell you how to buy cheap laser cutter equipment and what you should pay attention to.

Now this article will tell you something about the best laser cutting machine for small business, I hope it will be helpful to you.

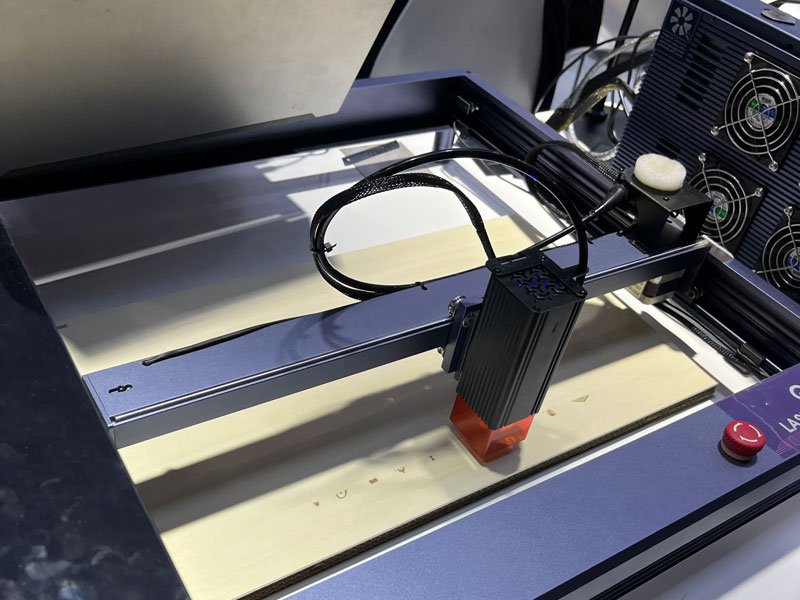

Best laser engraver for small business

Portable small laser engraving machines have completely opened the door to ordinary people. With just a mobile phone, they can easily engrave text, graphics or other more complex ideas using ordinary materials such as paper that can be found everywhere in daily life. It is extremely convenient for ordinary people and people engaged in design and creation to use it.

The small laser engraver produced by DOWELL Laser can not only engrave and mark metal, wood, and mobile phone cases. Simple to operate and easy to carry, suitable for small businesses.DOWELL can provide you with the most affordable small laser engraver on the market.

The laser of the small business laser engraver is a fiber laser, which can mark and engrave metal surfaces and some non-metal surfaces. Different patterns, characters and logos can be carved out. Due to its portability and ease of operation, marking and engraving can be easily performed on the production site or outdoors.

Best wood laser cutter for small business

The small wood laser cutter can be used at home. It occupies a small area and is easy to operate. It can carve wood, two-color boards, plexiglass, plates and other non-metallic materials. It can realize various functions such as engraving and cutting. It is a co2 laser engraver.

It is more suitable for use in some handicrafts, decorations, children’s toys, etc.

What is a metal laser cutter?

Laser metal cutting machine is a laser cutter equipment specially used to cut and process metal materials. The mainstream on the market is co2 laser cutter, fiber laser cutter, and YAG laser cutter. Among them, co2 laser cutting machine has strong cutting ability and wide range. The mainstream laser cutting equipment in the market, fiber laser cutter is the latest technology, coupled with relatively low technical requirements, the metal fiber laser cutter equipment is gradually popular.

Comparison of laser cutting machine VS laser engraving machine

The laser cutting equipment can cut all kinds of complicated graphics. Because it uses light energy to cut, it does not need a fixture. Just put the material on the worktable and cut it, so there will be no damage to the surface of the material, which is different from others. For cutting, such as a sawing machine, it can only cut straight lines, not irregular shapes, arcs, etc.;

The laser engraving machine cannot process some small graphics, and in the process of processing, it needs a fixture, which also damages the surface of the material, and when cutting, it will have an R angle, which is more troublesome to operate.

If you want to buy the best affordable laser cutter, you need to compare multiple brand manufacturers, refer to the thickness of the metal sheet or wood to be cut, the size of the cut, the reference configuration and the size of the power, and choose the engraving machine product that suits you.

Features of laser metal cutting machine

Sheet metal laser cutter cut metals with high precision, fast speed, no dross, no wrinkles, high processing accuracy, manual work efficiency increased by 3 times, by many manufacturing industry favorite.

- High precision: suitable for cutting precision parts and fine cutting of various craftsmanship and paintings.

- Fast speed: more than 100 times that of wire cutting.

- The heat-affected zone is small and not easy to deform. The cutting seam is smooth and beautiful, without subsequent processing.

- High cost performance: The price is only 1/3 of the same performance CO2 laser cutter, and 2/5 of the same performance CNC punching machine.

- The use cost is very low: only 1/8~1/10 of the similar CO2 laser machine, the hourly cost is only about 18 yuan, and the hourly cost of the CO2 laser cutter is about 150-180 yuan.

- The follow-up maintenance cost is very low: only 1/10~1/15 of the similar CO2 laser cutter and 1/3~1/4 of the equivalent CNC punching machine.

- Stable performance to ensure continuous production. The solid-state YAG laser is one of the most stable and mature products in the laser field.

Desktop Laser cutter composition

Desktop laser cutting machine includes: laser head, fiber laser, laser laser cutting software system, control panel, servo motor, water cooling system, bed

- Laser power: 500w/1000w/1500w/2000w/3000w/4000w/6000w/8000w/12000w/15000w/20000w

- Current laser system/laser control software: Shanghai WEIHONG/Shanghai CYPCUT

- Laser head:WSX ,RAYTOOLS,OSPRI

- Laser source: IPG, MAX, Raycus, GW

- Power supply:380v

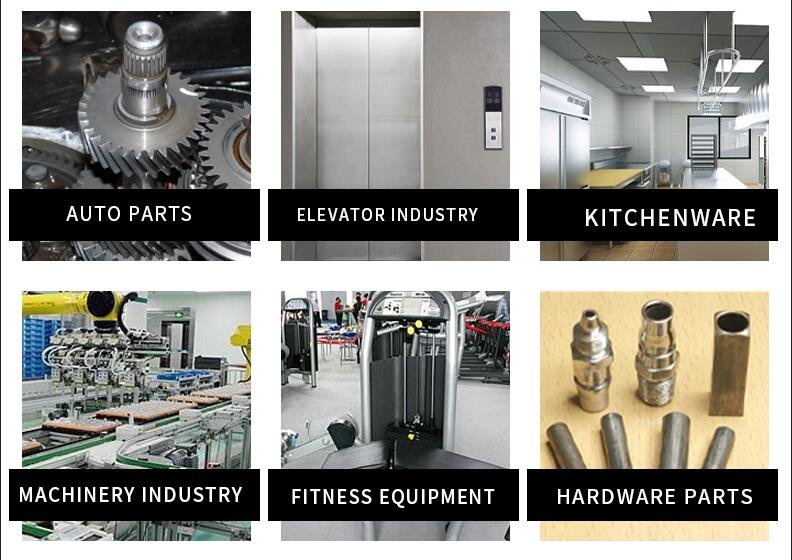

The use of metal fiber laser cutting in the manufacturing industry

Fiber laser metal cutting machine Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, gifts and crafts, tool processing, decoration, advertising, metal foreign trade processing various manufacturing Processing Industry.

laser cut materials : low carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel plate, pickling plate, aluminum zinc plate, copper and many kinds of metal multiple materials.

How does the fiber laser cutter work?

The matel cutting machine is a dense beam of light in the form of light with high concentration and high heat through the laser stroke. The beam irradiates the surface of the material, uses the high temperature generated to melt the material and uses the high pressure gas generated by the beam coaxial to remove the melted Exhaust gas material, so that the purpose of cutting metal is achieved.

From here we can see that laser machine is essentially different from traditional machining. The lazer cutting machine generates a laser beam through the laser transmitter. This laser beam will enter the external circuit system and converge to form a high-density and high-intensity laser beam, and then directly irradiate the surface of the material.

After the material is irradiated, its temperature rises rapidly until it reaches its surface. At this time, the material begins to vaporize to form holes, and then the laser beam begins to move on the surface of the material to form a cut.

Most materials can be cut by laser. Therefore, laser cutting plays a very important role in industrial manufacturing. Most materials can be cut and deformed regardless of their hardness. However, it does not deny that some high emissivity materials will also make laser cutting very difficult or even impossible to cut because of their excellent thermal conductivity properties.

The fiber laser metal cutting machine is also loved by many electrome chanical manufacturing industries because of its features such as no burrs, no wrinkles, and high processing accuracy. Because of its precise micro-control operation, CNC laser cutting can cut materials of different shapes and sizes very conveniently.

Questions to consider when buying an industrial laser cutters

Laser cut machine is actually a very high threshold market, the purchase of equipment must be polished, very familiar with the purchase of equipment to buy quality and quantity of equipment, even if the long-term business of laser cuttier machine bosses also have to go out of sight, not to mention just entering the line of white.

But just entered the industry, whether for the purpose of industry testing, or the hands of the money really can not be turned around, the demand for used equipment is real, so we are today to talk about the purchase of laser cutting tools as an example, what issues should be considered when buying laser cutting equipment.

First, set the right mindset

Buy laser cutting system do not hold the mentality of picking up, picking up is a probability event, hold this mentality to buy equipment, either do not happen to be the right equipment to delay the schedule, or for the benefit of reluctantly bought a less suitable for their own equipment, or be used to take advantage of this mentality to cheat the funds.

So we buy laser cut machine is the first priority is to set the right mindset, firmly believe in the truth that a penny is worth a penny, the face of equipment significantly lower than the market price must be vigilant.

Second, check the identity

Now the network has developed very convenient, before the field inspection equipment, we can understand some of the basic information about the equipment through a number of ways.

For example, the equipment purchase contract, manual, after-sales service, etc., if inadvertently lost, we can also ask the seller to take a picture of the nameplate on the body, mainly to understand the age of the equipment and the manufacturer’s sources. Years of use and manufacturers sources related to the quality of equipment, service life, and naturally, our prices are closely related.

Third, field visits

We can watch the pictures and videos of the equipment through the Internet, and after the initial satisfaction, we also need to visit the field to see the equipment with our own eyes.

First look at the appearance of the equipment, and then look at the details of the equipment, check the degree of wear and tear of the parts of the equipment, especially important accessories, such as laser cutting system cutting head, laser, motor, etc., these important accessories if there is a problem, buy back often break down, the cost of repair and replacement will undoubtedly increase our costs.

Fourth, open the machine to check the goods

Everything looks almost right, it is also necessary to turn on the machine for a trial run.

Normal start-up, add materials, observe whether the equipment is running normally, there is no abnormal heat or abnormal noise, the efficiency and quality of production is in line with production requirements, etc.

V. Sign the contract

The contract should include the name of the equipment, model, quantity, main parameters, scope of supply, price and payment method, the responsibility of both sides, compensation method, etc. If unpleasant things happen subsequently, at least we can take up the legal weapon to protect ourselves.

4 Features of CO2 laser cutter machine

- In the laser cutting co2, gas is the medium that generates the laser beam, and the beam is transmitted through the reflector. The maintenance cost is high, the front mirror and the rear mirror are expensive, the life of the turbine bearing is short, and the replacement cost is high.

- The CO2 laser has a complex structure, high maintenance costs, and large beam divergence during processing, which is not suitable for large-format processing. The speed is very slow when processing thick metal plates. The cutting speed of fiber laser cut machine is 2-3 times higher than that of CO2, and the cutting section is smooth.

- Due to the purity of CO2 gas, the c02 laser cutter will be polluted in the resonant cavity and needs to be cleaned regularly, which requires more routine maintenance. For a multi-kilowatt laser machine co2, this item requires at least US$20,000 per year.

- The co2 laser cutter machine can cut non-metallic materials, such as cloth, leather, wood, acrylic, paper and other non-metallic softer materials.