The advancement of science and technology has driven the development of the industrial market. Because of its fast cutting speed and high precision, fiber laser cutting copper is an intelligent metal cutting equipment and is widely sought after in the manufacturing field.

Many customers have questions about best materials for laser cutting. I hope this article can help you.

Laser cutting metal materials: metal sheet, carbon steel sheet, stainless steel sheet, copper sheet, aluminum alloy sheet, galvanized sheet, electrolytic sheet, silicon steel, titanium alloy, galvanized plate and other metal materials.

This guide will introduce you to some of the laser cutting materials guide we offer, and their introduction to laser cut copper , stainless steel, carbon steel, brass, silver, alloys.

What laser can cut metal

There are many kinds of industrial laser light sources, in addition to optical fiber, ultraviolet light, green light, CO2 and so on. For laser cut metal, optical fiber is the easiest to be absorbed, and the quality of cutting metal is better and the speed is faster.

Whether it is automobile production, shipbuilding industry, steel structure industry, metal furniture, fitness equipment, agricultural machinery production, industrial market, etc., 10,000-watt-class high-power large laser cutters are becoming more and more popular, not only increasing their own output, but also saving labor costs.

Types of laser cutters

Laser type

- Fiber industrial laser cutters

- CO2 gas lazer cutter

- YAG lazer cutter

Power classification

- Low power : 1000w-3000w laser cutter machine

- Medium power : 4000w-6000w lazer cutting machine

- High power : 12kw-30kw laser cutting systems

Cutting material

- Laser metal cutting machine: cutting metal materials, steel plate, stainless steel plate, carbon steel, brass, aluminum plate, etc.

- Non-metallic laser cnc cutting machine: cutting non-metallic materials, foam, carton, glass, cloth, leather, etc.

Bed size:

- Small format laser cutter: 2513 1515

- Standard laser cutter: 3015 4015 4020 6025

- Large format laser cutter: length over 8m, 8025 14031, etc.

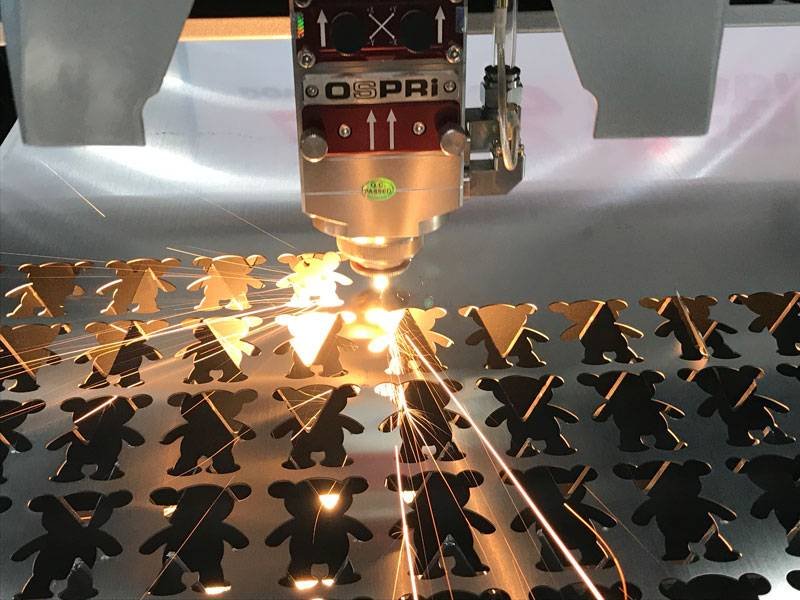

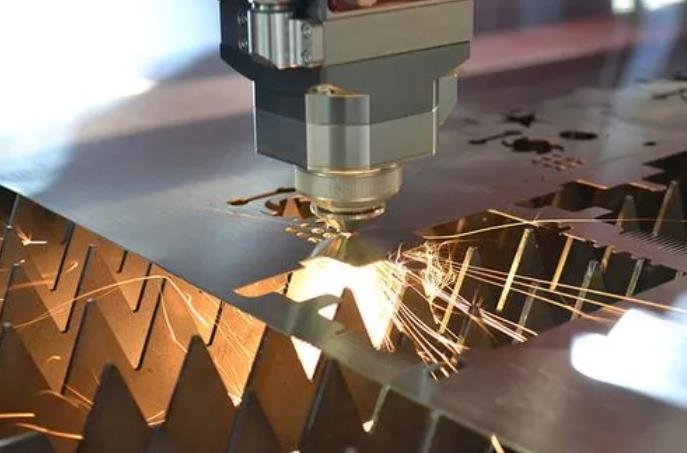

Sheet metal laser cutting advantages

- High precision, positioning accuracy 0.05mm, repeat positioning accuracy 0.02 mm;

- The incision is narrow, and the incision width is generally 0.10-0.20mm;

- The cutting surface is smooth without burrs;

- Fast speed, non-contact cutting, little thermal influence on the cutting edge, basically no thermal deformation of the workpiece, and no secondary processing is required.

- Not affected by the hardness of the material to be cut, the laser can process steel plates, stainless steel, aluminum alloy plates, hard alloys, etc. No matter what the hardness is, it can be cut without deformation.

Laser cutting sheet metal

Common laser cut metal panels on the market include carbon steel, stainless steel, aluminum, brass, etc. Now metal laser cutting can cut carbon steel to 60mm. It can cut 70mm for stainless steel and 60mm for aluminum laser cutting.

Laser cut copper sheet

Copper is a highly reflective material and needs to be cut with an “anti-reflection device”.

Nitrogen gas is used for laser cut copper thickness below 1mm;

Oxygen is used for fiber laser cutting copper thickness below 2mm.

When the laser cutting copper sheet plates or pipes, nitrogen is the best auxiliary gas.

When the thickness of metal copper reaches 2MM, it cannot be processed only with nitrogen, and oxygen must be added to oxidize it to achieve perfect cutting.

Laser cutter for stainless steel

Laser cutting stainless steel is generally cut with nitrogen gas, with high energy, the incision is white and bright, does not oxidize and does not change color, the edge of the cut surface has no burrs, and can be directly welded without secondary treatment.

If oxygen cutting is used, the fiber laser cutting stainless steel speed will be faster and the cutting edge will become black.

When performing specific cutting, the parameters should be adjusted according to the thickness of laser cutting stainless steel, so that the cutting efficiency can be further improved.

Laser cutter for aluminum

Aluminum and its alloys have high reflectivity and thermal conductivity, and high energy is required for laser cutter aluminum

Aluminum plate is more suitable for cutting with nitrogen gas, and the section after cutting by aluminum laser cutter is relatively smooth.

Alloy steel laser cutting

Most alloy steels have good trimming qualities by laser cutting.

As long as the parameters are set properly, the laser cut steel sheet can cut straight and slag-free cutting edges. However, for tungsten-containing target steel and hot die steel, erosion and sticky slag will occur during laser for cutting steel processing.

Laser cutting inconel

Laser cutting inconel is similar to stainless steel cutting. Due to the high viscosity of molten nickel, the slag is easy to stick to the back of the cutting seam, which is easy to produce burrs. It is usually better to use oxygen to cut.

Laser cutting titanium alloy

Laser cutting of titanium alloys is often used in aircraft production. Cutting quality should use air as auxiliary gas, there will be a small amount of dross on the back, but it is easy to remove, so it is easier to control the cutting effect.

When oxygen is used as auxiliary gas, the chemical reaction is violent and the cutting speed is fast, but improper operation may cause over-combustion.

Precautions for laser cutter aluminum

- Aluminum is not resistant to high temperature, and the appearance of micro-cracks will be accelerated under high temperature, so quality control should be strengthened.

- In order to ensure the best state of aluminum laser cutting, the operator must accurately calculate the laser cutting parameters with the precise laser cutting software.

- Aluminum has a reflective effect on the ability of laser generation. Operators should take good protection and wear laser protective glasses or protective masks.

Influencing factors of copper laser cutting machine:

- Thickness limitation: The cutting thickness of laser cut copper is limited, which is smaller than other cutting methods.

- High cutting cost: The machine and technology cost is high, which is not economical for small batch production.

- High requirements on materials: laser cutting copper requires conditions such as high surface finish and low oxidation degree, otherwise the cutting quality will be affected.

The copper sheet cutting machine is suitable for production that requires high precision and small batches. Problems such as high machine cost and limited cutting thickness need to be further resolved in order to achieve wider application.

The Best Laser Cutting Projects for You

This is just an introduction to some of the high quality materials that dowell laser machine can use for metal laser cutting. To learn more, check out Dowell’s best metal cutting laser factories – and find the best laser cutting project for you.

Consult us for laser cut designs now and get an instant quote!