Laser cutting technology has revolutionized the steel industry, offering unparalleled precision, efficiency, and versatility. From automotive manufacturing to architectural design, the applications of steel laser cutter machines are vast and varied.

This article explores the various aspects of laser cutting solutions for the steel industry, highlighting the benefits, applications, and future trends of this advanced technology.

What is a Steel Laser Cutter Machine?

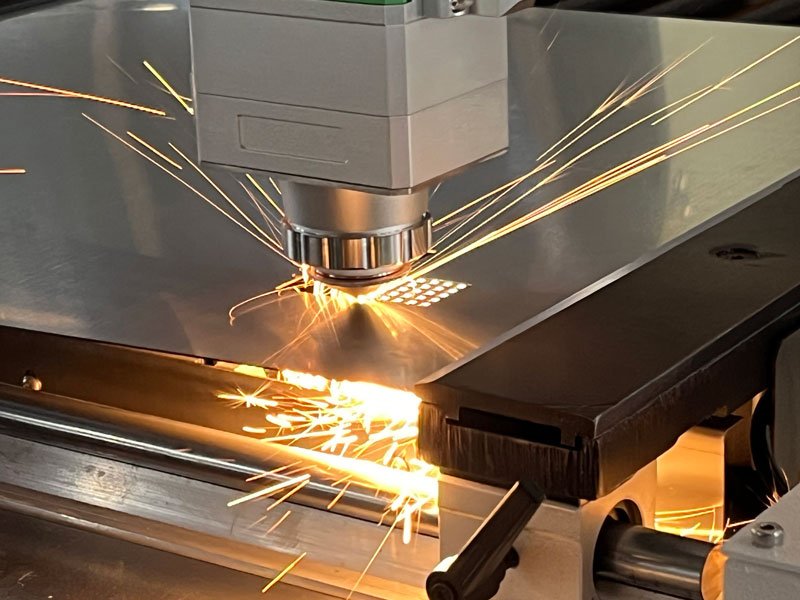

A steel laser cutter machine uses a high-powered laser to cut through steel with extreme precision. The laser beam melts, burns, or vaporizes the material, resulting in a clean and accurate cut. There are several types of laser cutting machines used for steel, including CO2 lasers, fiber lasers, and YAG lasers, each with its unique advantages.

- CO2 Lasers: Utilize carbon dioxide gas as the lasing medium, ideal for cutting thicker materials but may require more maintenance.

- Fiber Lasers: Use optical fibers doped with rare-earth elements, known for high efficiency, low maintenance, and the ability to cut both thin and thick materials.

- YAG Lasers: Employ a solid-state laser medium and are suitable for cutting thin materials with high precision.

Key components of a steel laser cutter machine include the laser resonator, cutting head, motion system, and control system, all working together to achieve precise cuts.

Benefits of Using Industrial Metal Laser Cutting Machine

- High Precision and Accuracy Laser cutters can achieve incredibly fine and detailed cuts, essential for applications requiring tight tolerances. The precision of laser cutting surpasses traditional methods, ensuring high-quality results.

- Increased Efficiency and Speed Laser cutting is significantly faster than conventional methods like sawing or milling. This speed reduces production times and lowers labor costs, making it an efficient solution for high-volume manufacturing.

- Versatility in Cutting Different Steel Types and Thicknesses Laser cutters can handle various steel types, including carbon steel, stainless steel, and alloy steels, with different thicknesses. This versatility makes them suitable for a wide range of applications.

- Reduced Material Waste The precision of laser cutting results in minimal waste, which is both cost-effective and environmentally friendly. The narrow kerf ensures optimal material usage.

- Clean and Smooth Edges Laser cutting produces smooth edges that often require little to no post-processing, reducing the need for additional finishing work and saving time and resources.

Applications of Steel Laser Cutter Machine for Metal

- Automotive Industry Used for manufacturing components like brackets, exhaust systems, and body parts. The precision and speed of laser cutting meet the high standards of the automotive industry.

- Aerospace Industry Essential for creating lightweight and durable components used in aircraft and spacecraft. Laser cutting ensures the high precision required for aerospace applications.

- Construction and Architecture Employed in the creation of custom designs, structural elements, and decorative panels. Laser cutters enable architects to realize complex and intricate designs.

- Medical Devices Used to produce surgical instruments, implants, and other medical devices. The high precision and cleanliness of laser cutting meet stringent medical standards.

- Artistic and Decorative Uses Artists and designers use laser cutters to create intricate designs and sculptures from steel. The precision of laser cutting opens up endless creative possibilities.

Choosing the Right Laser Cutting Machine for Steel

- Power: Higher power machines can cut thicker materials. Choose the power level based on the thickness of steel you typically work with.

- Speed: Faster machines increase productivity. Balance speed with the precision required for your applications.

- Type: CO2, fiber, and YAG lasers each have unique benefits. Select the type that best fits your specific needs.

- Cost: Evaluate the purchase, maintenance, and operating costs to ensure the machine fits within your budget.

Best Practices for Operating Steel Laser Cutter Machines

- Proper Setup and Calibration Ensure the machine is correctly set up and calibrated for the specific material and thickness to achieve the best results.

- Regular Maintenance and Cleaning Keep the machine well-maintained to ensure consistent performance. Regularly clean lenses, check alignment, and replace worn parts.

- Safety Precautions and Protective Measures Follow all safety protocols, including wearing protective gear and ensuring proper ventilation. Never leave the machine unattended during operation.

- Using Assist Gases for Enhanced Cutting Quality Use gases like nitrogen or oxygen to improve cut quality by preventing oxidation and blowing away molten material.

Innovations and Future Trends in Laser Cutting Technology

- Advances in Laser Power and Efficiency Continuous improvements in laser power and efficiency enable faster and more precise cutting of thicker materials.

- Automation and Integration with CNC Systems Integration with CNC systems enhances precision and allows for complex designs and automated production processes.

- Environmental Considerations and Energy Efficiency New technologies focus on reducing energy consumption and environmental impact, making laser cutting more sustainable.

- Emerging Applications and Market Trends As technology advances, new applications in various industries continue to emerge, expanding the possibilities of laser cutting.

Case Studies and Success Stories

Several companies have successfully integrated laser cutting technology into their operations, resulting in significant productivity gains, cost savings, and improved product quality. For example, an automotive manufacturer reduced production time by 30% and achieved higher precision in component fabrication by adopting fiber laser cutting machines.

Conclusion

Laser cutting solutions have transformed the steel industry by offering unmatched precision, efficiency, and versatility. By understanding the benefits and best practices of using steel laser cutter machines, industries can achieve superior results and stay competitive in the market. Embracing this technology paves the way for innovation and growth, making it an indispensable tool in modern manufacturing.