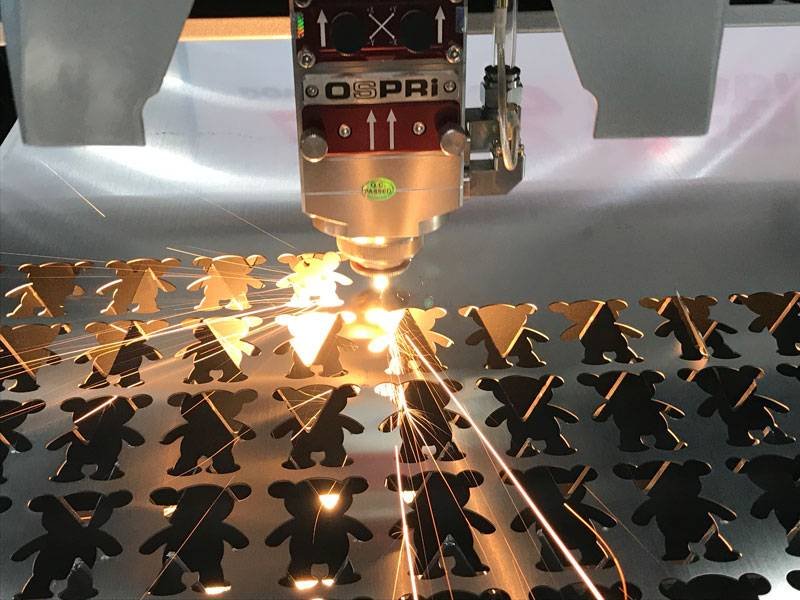

Sheet metal laser cutting machine compared with the traditional cnc equipment for cutting metal sheets, plasma cutting machine, water jet cutting machine, or cnc drilling machine, the cutting precision is high, the speed is fast, and it saves more costs for business owners, so it is the best choice for cutting metal sheets best choice.

If you want to know more about laser metal sheet cutting machines, watch the following article.

Which sheet metal laser cutter is best for cutting sheet metal?

Due to the different thicknesses of the sheet metal material to be cut, the size of the laser cutting machine to be missed is also different.

Generally, the thin sheet metal on the market is less than 7mm. It is entirely sufficient to use a 3015-3000w laser cutting machine for cutting. If you cut carbon steel, you need a higher power.

Why is laser sheet cutting machine Important?

1. Laser cutting does not need to open the mold of the equipment, which saves the mold cost;

2. It can cut any radical graphic limit, automatic typesetting by the CNC operating system, save raw materials,

3. Laser cutting is formed in this way; the cutting surface is smooth, no need for secondary grinding, and the processing cost is low;

4. Fast cutting speed, high precision, saving time;

5. The operation of the staff is straightforward;

6. No harmful gas will be produced during the cutting process, which reduces environmental pollution;

7. It can be processed in batches to meet the processing needs.

What is the process of laser cutting

When performing laser cutting of sheet metal, it is necessary to carry out numerical control programming, and it is necessary to calculate the blanking size, layout, and setting of process parameters for sheet metal materials. The following laser cutting process steps will be introduced to you.

- Step 1:

Output the graphics that need to be drawn into the CNC operating system and convert them (require the outer contour of the part to be closed);

- Step 2:

The size, material, and layout of the sheet metal to be cut;

- Step 3:

Use laser cutting: fillet process (to obtain sharp edges and blunt) or loop process (to obtain sharp angles); automatically load the gas type, cutting speed, and set the return material;

- Step 4:

The machining sequence is optimized, the NC machining program is generated, and the program is transmitted.

The above is the laser cutting process, if you want to know more, you can contact us.

How much does a metal laser cutter cost

The laser metal cutting machine price is generally between 15,000 US dollars and 500,000 US dollars because each manufacturer has different laser cutting machine capacities, laser cutting machine configurations, parts, power, cutting table, and other brands, which lead to additional metal laser cutting machine costs.

Suppose your budget for laser cutting machines is low early. In that case, if you want to purchase inexpensive laser cutters, you can buy used laser cutting equipment, which can save you costs, but you should pay attention to the later maintenance of such machines.

What are the thickest metals (aluminum, steel etc.) cut?

Plate thickness (t) standard: the thickness of the plate can range from 0.05mm-150mm

The 6000w laser cutting machine can cut aluminum alloy plates up to 40mm, and stainless steel plates up to 50mm. When cutting stainless steel plates with a thickness of 3~10mm, it can achieve a fast bright surface cutting of 18~20mm/s, which is twice the normal standard cutting speed. , It can also use compressed air or nitrogen to cut carbon steel within 12mm, and the cutting efficiency is six to seven times that of oxygen cutting carbon steel.

Was metal cutter machine cut using oxygen or nitrogen?

Laser cutting machines use different auxiliary gases for cutting different materials. Depending on the thickness of the cutting material, the gas pressure, and flow required are also different. Every laser cutting machine manufacturer is another.

Common auxiliary gases are air, oxygen, nitrogen, and argon.

Oxygen for cutting carbon steel:

Its purity requirement is generally 99.5% or higher, which supports combustion and blows off the cut melt.

Nitrogen for cutting stainless steel:

It is used to prevent oxidation reactions and blow off the melt and has high requirements on nitrogen purity.

- Stainless steel above 8mm generally requires a purity of 99.999%) The pressure requirement is relatively large, generally above 1Mpa.

- Cutting stainless steel above 12mm or thicker to 25mm requires higher pressure, above 2Mpa or higher.

In terms of cost, oxygen for cutting carbon steel is relatively cheap, and the amount of nitrogen used for cutting carbon steel is large, and the amount and purity of nitrogen are very high, and the cost is very high.

3000w Metal cutter machine parameters use for cutting 20mm sheet

- Cutting speed: 1.2-1.8 m/min

- Oxygen pressure: 8-10 bar

- Nozzle diameter: 1.2-1.5 mm

- Cutting speed: 50-70 inches per minute (IPM)

- Oxygen pressure: 116-145 (PSI)

- Nozzle diameter: 0.047-0.059 inches

What machine cuts metal

1.Grinding wheel cutting machine

It is used for steel cutting; the grinding wheel is cut under high-speed rotation, is easy to operate, easy to use, and has a wide range of application scenarios. It can be used when cutting steel pipes, and the price is low.

2.Saw cutting machine

Compared with the traditional cutting machine, the teeth on the saw blade are used to cut, which will be used with a sawing device. In the machining industry, a suitable saw blade will be configured according to the metal’s hardness for cutting.

3.Flame cutting machine

The flame-cutting machine is a cutting method of heating and melting. It can heat the chemical reaction between oxygen and hot steel so that the metal becomes soft and melts to achieve the purpose of cutting. It can only cut metals with low melting points. For stainless steel, copper, etc., aluminum and other metals are not applicable.

4.Plasma cutting machine

A plasma cutting machine is a cutting method of heating and melting. It uses the heat of an ion arc for heating and can form a cut on the workpiece. It can cut metal with a thickness of no more than 100mm. The cutting surface is smooth and suitable for different metal cutting.

5. Laser metal sheet cutting machine

The laser cutting machine uses laser beam heating, melting, or vaporization to cut metal. It is suitable for high-efficiency and precise cutting on thin steel plates not exceeding 30mm. When cutting, it can be selected according to the characteristics of the metal material.

6.Water jet cutting machine

Using high-pressure water flow for metal cutting, the accuracy can be controlled at 0.4mm, and any metal can be cut at will; whether it is a curve or a unique shape, it can be cut and processed at once.

Can a laser cutter cut metal

Yes, laser cutting machines can cut metal and non-metal, there are many types

- Fiber laser cutting machine for cutting sheet metal

- CO2 laser cutting machine is used to cut leather, cloth, acrylic, sponge and other non-metallic materials

Can a co2 laser cut metal

YES.

Carbon dioxide laser cutting machine can cut metal, but the efficiency is very low, generally not used in this way. CO2 laser cutting machine, also known as non-metal laser cutting machine, is specially used for cutting non-metal materials.

Can you cut aluminum with a laser

YES

Laser cutting machine can cut aluminum: Whether the laser plate cutting machine can cut aluminum plate depends on the laser machine’s power. It is also possible, but the processing cost is high. This is a highly reflective material.

Where to buy a laser cutter

You can search for relevant sheet metal laser cutting machine manufacturers on Google, check their websites, and learn about the company’s production capacity, scale, shipments, and after-sales service. Find a few more for comparison. Metal laser cutting machine cost, choose the equipment that fits your budget, or go to the manufacturer for an on-site inspection.

How many watts does a laser need to cut metal

The models of lasers on the market are 1000w, 1500w, 2000w, 3000w, 6000w, 8000w, 10000w, 12kw, 15kw 20kw 30kw, and the thickness of the plates cut by lasers with different powers is different.

Determine the plate thickness you want to cut and choose the appropriate laser, which will get twice the result with half the effort.

What are laser cutting machine side effects ?

Long-term operation of the laser cutting machine may cause damage to the skin and mucous membranes, and a burning sensation may occur. Therefore, wear protective masks, laser protective glasses, gloves and other safety measures during operation.

If you need to contact the laser cutting machine for a long time, you should go to the hospital to check the eyes and skin regularly to rule out whether there is any damage.