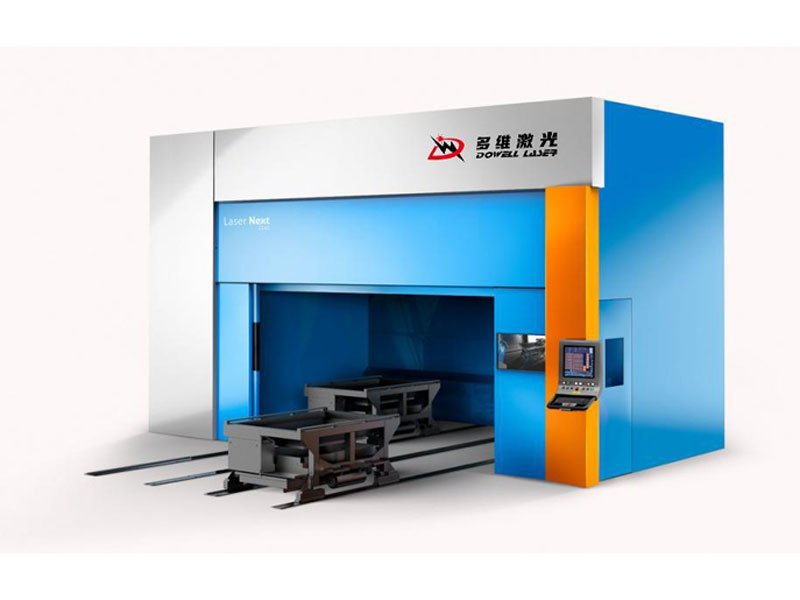

The 5 axis laser cutting machine is a highly advanced and flexible system that can accurately cut complex 3D shapes and parts.

The system consists of a three-dimensional five-axis laser cutting host, laser, chiller, stable power supply, air compressor, three-dimensional cutting head, FANUC control system, etc.

Five-axis laser cutting equipment is suitable for Aerospace, automobile steamship, machinery manufacturing, elevator manufacturing, advertising production, household appliance manufacturing, medical apparatus, hardware decoration, fitness equipment, metal external processing services and other manufacturing industries, but the most popular is the application of automobile heat formation.

For some high-precision and complex sheet metal parts, they offer the advantages of high cost performance and high performance, and are very popular among sheet metal enterprises

The high-performance one-time processing eliminates the tedious process, and the high flexibility solves the problem of multi-material cutting, shortens the proofing cycle, and brings strong competitiveness to customers.

Three-dimensional five-axis cutting can cut gradient slits that are wide on the outside and narrow on the inside or narrow on the outside and inside, so that the oil screen pipe has better performance. It is one of the typical applications in the petrochemical industry.

The creation of curved surface structures of car bodies and the growing demand for automobile hot forming have driven the sales data of three-dimensional five-axis cutting machines, which were once ahead of other industry data.

The mechanization and integration of agriculture have promoted the great development of agricultural machinery. The high cost performance and technical flexibility of three-dimensional five-axis cutting machines are very suitable for the batch manufacturing and technological update of agricultural machinery, which is very popular among agricultural machinery manufacturers.

5 axis lasers can move in five directions, providing greater flexibility and precision compared to 3 axis lasers, which move only in X, Y, and Z directions.

Regular maintenance includes routine inspections, cleaning optics and components, and periodic calibration to ensure optimal performance.

Industries such as automotive, aerospace, medical device manufacturing, and electronics benefit significantly due to the precision and versatility of 5 axis laser systems.

While the initial investment is higher than traditional laser systems, the efficiency, precision, and reduced material waste often result in long-term cost savings.

Consider factors such as the materials you work with, the precision required, and the level of manufacturer support available. Researching and comparing different brands and models is also crucial.

5 axis lasers are highly versatile and can cut a wide range of materials, including metals, plastics, composites, and more. However, it’s important to verify compatibility with specific materials before purchasing.

Safety measures include wearing protective gear, proper training for operators, and ensuring systems are equipped with emergency stop mechanisms. Regular safety checks and adherence to protocols are also essential.

5 axis lasers enhance production efficiency by allowing for faster, more precise cuts, reducing the need for additional finishing processes, and minimizing material waste.

Environmental benefits include lower energy consumption due to modern, efficient designs and reduced waste through precise cutting, which minimizes leftover material.

Future advancements may include integration with artificial intelligence for even more precise control, increased automation, and further improvements in energy efficiency and material compatibility.

Do you want to know more about 3D 5 axis laser cutting equipment now? You can tell us the material to be cut and the required power, and we will arrange for a professional engineer to contact you.

15 years of CNC laser cutter equipment manufacturing experience, making cutting easier

We will contact you within 1 working day, please pay attention to the email with the suffix “@dwlaser.net”.