With the rapid development of science and technology, laser technology has opened up a new world for some idea designs. More and more people like DIY art and personalization. This article will mainly describe the differences between laser engraver and cutter machine, hoping that you can make a wise choice when carrying out the project.

What is Laser Cutting and Engraving?

Laser cutting and engraving is an advanced processing technology that uses high-energy laser beams to cut or engrave materials. By precisely controlling the energy and path of the laser beam, fine processing of various materials can be achieved, and it is widely used in industrial manufacturing, art design, personalized customization and other fields.

Advantages of Laser Engraver and Cutter

High precision: Laser processing has extremely high precision and can achieve micron-level processing accuracy.

Flexibility: Laser processing is not limited by material hardness and can process various materials.

Non-contact processing: Laser processing is a non-contact processing method that avoids the problems of tool wear and material deformation in traditional processing methods.

High efficiency: Laser processing is fast and efficient, which can greatly shorten the processing cycle.

No pollution: Laser processing is a clean processing method that does not produce harmful substances.

Difference Between Laser Engraver and Laser Cutter

- Laser cutting machine: Mainly used for cutting materials. The energy of the laser beam is strong enough to completely cut the material. Suitable for cutting metal, wood, plastic, leather and other materials.

- Laser engraving machine: Mainly used for engraving on the surface of materials. The energy of the laser beam is low and will not completely cut the material, but will form a pattern by removing a thin film on the surface of the material. Suitable for engraving wood, leather, acrylic, glass and other materials.

Laser Wood Cutter and Engraver

Wood laser engraver and cutter is a laser processing equipment specifically for wood materials. It uses high-energy laser beams to cut, engrave, mark and other processes on wood, and has the characteristics of high efficiency, precision and flexibility.

Features of Wood Laser Cutter and Engraver:

- High efficiency: The laser cutting speed is fast and the processing efficiency is high.

- Precision: The cutting edge is smooth and neat, and the dimensional accuracy is high.

- Flexibility: It can process various complex patterns and texts, and has strong adaptability.

- Environmental protection: No pollution, no dust, and meets environmental protection requirements.

Application Areas of Laser Engraver and Cutter for Wood:

- Furniture manufacturing: Cutting wood boards and making wooden furniture parts.

- Crafts production: Carving wooden crafts and making wooden models.

- Packaging industry: Making wooden packaging boxes and wooden pallets.

- Advertising industry: Making wooden signboards and wooden display racks.

CNC Laser Cutter and Engraver

CNC laser cutter and engraver is a processing equipment that integrates computer numerical control system and laser technology. It can not only process wood, but also cut and engrave a variety of materials such as metal, plastic, leather, etc.

CNC laser engraver and cutter Features:

- High degree of automation: Through computer control, automatic production is realized.

- High processing accuracy: It can achieve micron-level processing accuracy.

- Strong adaptability: It can process parts of various complex shapes.

- Flexible production: The processing program can be quickly adjusted according to demand.

Application areas:

- Industrial manufacturing: Cutting metal sheets, electronic components, automotive parts, etc.

- Advertising industry: Making signs, display stands, acrylic products, etc.

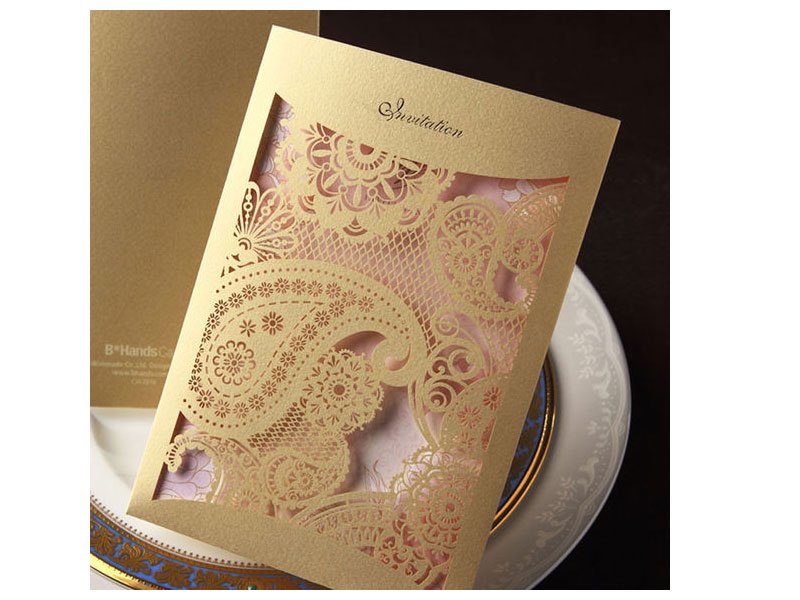

- Art design: Carving wood products, leather products, crafts, etc.

- Personalized customization: Making personalized gifts, souvenirs, customized furniture, etc.

Metal Laser Cutter and Engraver

Metal Laser Cutter and Engraver is a sophisticated machine that utilizes a high-powered laser beam to precisely cut and engrave metal materials. This technology offers remarkable precision, speed, and flexibility, making it an invaluable tool for various industries.

Types of Metal Laser Cutters and Engravers

Fiber Laser Cutters and Engravers:

- Ideal for cutting and engraving a wide range of metals, including stainless steel, carbon steel, aluminum, and copper.

- Known for their high power, fast cutting speeds, and excellent beam quality.

CO2 Laser Cutters and Engravers:

- Primarily used for cutting and engraving non-metallic materials like wood, acrylic, and leather.

- Can also be used for metal engraving on certain types of metal surfaces, especially those with a coating or a specific surface treatment.

Advantages of Metal Laser Cutting and Engraving

Precision: High-precision cuts and engravings with minimal heat-affected zones.

Speed: Fast processing times, increasing productivity.

Flexibility: Ability to cut and engrave complex shapes and designs.

Versatility: Can work with a wide range of metal thicknesses and types.

Reduced Waste: Minimal material waste due to precise cutting.

Applications of Metal Laser Cutters and Engravers

Manufacturing:

Cutting and shaping metal components for automotive, aerospace, and electronics industries.

Creating intricate metal parts for machinery and equipment.

Art and Design:

Producing custom metal sculptures, jewelry, and decorative items.

Creating personalized metal gifts and souvenirs.

Medical Industry:

Cutting and shaping surgical instruments.

Producing precise medical devices.

Electronics:

Cutting and etching circuit boards.

Creating intricate electronic components.

Best Laser Cutter and Engraver for Beginners

For beginners, it is very important to choose a laser cutting and engraving machine that is easy to operate, practical and affordable. You can refer to the following points when purchasing:

Power: Choose the appropriate laser power according to the thickness of the processing material.

Working area: Choose the appropriate workbench size according to the size of the workpiece.

Software: Choose a control software that is simple to operate and rich in functions.

Safety: The equipment should have complete safety protection measures.

After-sales service: Choose a manufacturer with perfect after-sales service.

A Complete Guide : What Is the Best Laser Engraver for Beginners

FAQ

Do Laser Cutter and Engraver Machines Cut Hardboard

Yes, laser cutters and engravers can effectively cut and engrave hardboard. Hardboard is a versatile material that responds well to laser processing, making it a popular choice for a variety of projects.

How to Choose the Right Parameters for Laser Cutting and Engraving?

- Power: Choose the right power according to the material thickness and type.

- Speed: Too fast speed may result in incomplete cutting, too slow speed will affect efficiency.

- Focus: The focus position has a great influence on the cutting quality and needs to be adjusted according to the material thickness.

- Gas: The type and pressure of auxiliary gas will affect the cutting effect, especially when cutting metal.

- Parameter settings usually need to be determined through experiments to determine the best value.

- Portable Small Laser Engraver Selection Guide

How Much Does Laser Cutting and Engraving Cost?

- Equipment cost: From a few thousand yuan to hundreds of thousands of yuan, depending on the power, working area and function of the equipment.

- Consumables cost: Mainly includes laser tube, nozzle, auxiliary gas, etc.

- Electricity cost: Laser cutting consumes a lot of electricity, and electricity cost is also an expense.

- Labor cost: Operator salary and training costs.

What Are the Safety Precautions for Laser Cutting and Engraving?

- Wear protective glasses: Prevent laser damage to the eyes.

- Good ventilation: The working environment should be well ventilated to avoid excessive smoke and dust.

- Stay away from flammable materials: When cutting flammable materials, pay attention to fire prevention.

- Regular maintenance: Clean the equipment regularly, check the optical components, and replace the wearing parts.