In today’s competitive manufacturing environment, 5 axis laser cutting machines have become an essential tool for companies seeking precision, flexibility, and efficiency in their production processes. These advanced machines offer unparalleled capabilities in cutting complex three-dimensional parts and assemblies.

Not only are these advanced machines capable of cutting complex shapes with high precision, they also offer unparalleled flexibility in material handling and cutting angles. Whether you are a manufacturer or distributor, finding the right 5-axis laser cutting machine manufacturer is critical to the success of your business.

This guide will explore the top manufacturers, key features to consider, pricing, and the benefits of different supplier locations.

What is 5 Axis Laser Cutting Machines

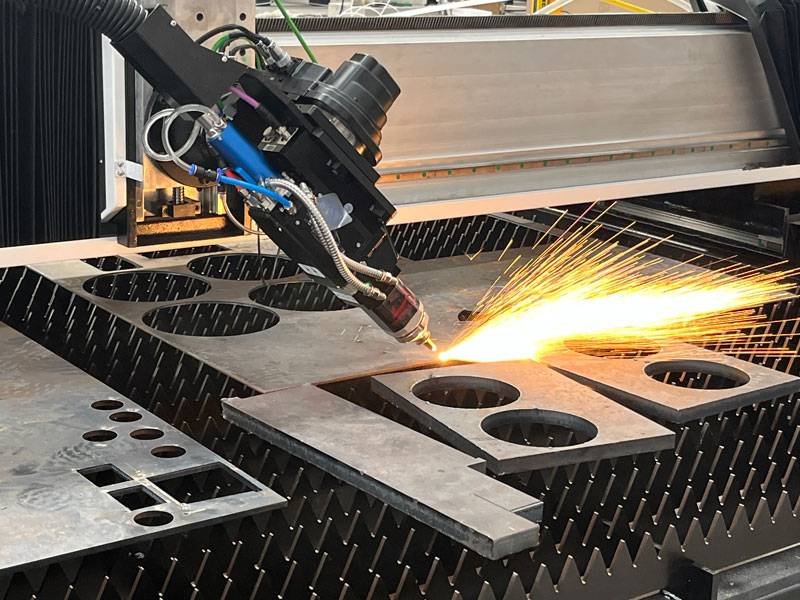

Before delving into the manufacturers, it’s essential to understand what makes 5-axis laser cutting machines unique. Unlike traditional 2D laser cutters, 5-axis machines can cut materials in five different directions: X, Y, Z (linear axes), and two rotational axes (A and B). This capability allows for intricate and precise cuts on complex geometries, making them ideal for industries such as aerospace, automotive, and medical device manufacturing.

Application Fields Of 5 Axis Laser Cutter

5-axis laser cutting is widely used in aerospace, automobile manufacturing, machinery manufacturing, electronics, molds, medical equipment, hardware and other industries. The main application fields include:

- Sheet metal processing: cutting, engraving, punching, etc.

- Mold manufacturing: trimming, fine carving, polishing, etc.

- Pipe processing: cutting, opening holes, beveling, etc.

- Three-dimensional structure processing: impellers, guide vanes, cavities, etc.

5 Axis Laser Cutting Pricing Considerations

Laser Power: Higher wattage lasers typically cost more but offer greater cutting capabilities.

Machine Size and Build Quality: Larger and more robust machines with higher build quality are generally more expensive.

Software and Control Systems: Advanced software and control systems can add to the cost but enhance functionality and ease of use.

Additional Features: Features such as automatic material loading, advanced cooling systems, and enhanced safety features can also influence the price.

5 Axis Laser Cutting Machine VS Traditional Laser Cutting Machine

- Higher processing accuracy: 5-axis linkage control can achieve higher precision processing, especially in cutting complex surfaces and three-dimensional structures.

- Higher processing efficiency: Multi-axis linkage can shorten processing time and improve processing efficiency.

- Larger processing range: 5-axis can achieve cutting at any angle, not limited by the shape of the workpiece, and expand the processing range.

- Higher processing flexibility: It can achieve multi-angle and multi-directional cutting to meet complex processing needs.

- Lower processing cost: High-precision and high-efficiency processing can reduce material loss, reduce labor costs, and reduce overall processing costs.

What Are The 5 Axis Laser Cutting Machine Manufacturers?

There are many excellent 5-axis laser cutting machine manufacturers around the world. Here are some well-known famous brands:

- Germany: Trumpf, Amada, Mazak

- Italy: Prima Power, Salvagnini

- Japan: AMADA, Mitsubishi, Yaskawa

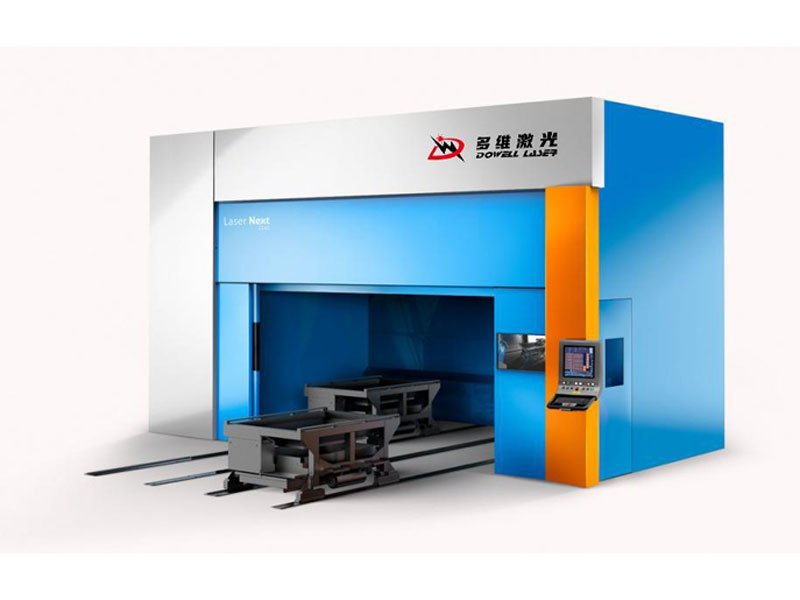

- China: HSG laser, bordor laser, hg laser. GWEIKE LASER, DOWELL LASER

How to Choose 5 Axis Laser Cutting Machine Manufacturer

- Qualification and strength of the supplier: Choose a supplier with good reputation and strong strength to ensure the quality and after-sales service of the machine.

- Performance and function of the machine: Choose a suitable machine model according to your processing needs, and pay attention to the machine’s performance indicators such as accuracy, power, and cutting speed.

- Service capability of the supplier: Choose a supplier that can provide high-quality after-sales service to ensure that you can get timely help when you encounter problems during use.

- Price of the machine: Choose the most cost-effective machine within the budget.

5 Axis Laser Cutting Supplier Location Benefits

- Proximity to Manufacturing Hubs: Manufacturers located in industrial regions may have quicker access to parts and materials, reducing lead times.

- Logistics and Shipping: Suppliers closer to your location can reduce shipping costs and delivery times.

- Local Support and Service: Having a supplier nearby can provide faster and more reliable technical support and service.

- Regulatory Compliance: Local suppliers are more likely to be familiar with regional regulatory requirements, ensuring compliance and smooth operations.

Conclusion

Selecting the right 5 axis laser cutting machine manufacturer involves careful consideration of various factors, including machine features, pricing, and supplier location. By understanding these aspects and evaluating the top manufacturers in China, you can make an informed decision that meets your specific needs and enhances your manufacturing capabilities.

Whether you prioritize precision, speed, or advanced features, the manufacturers listed in this guide offer a range of options to suit different industrial applications. Investing in a high-quality 5-axis laser cutting machine can significantly boost your production efficiency, accuracy, and overall competitiveness in the market.