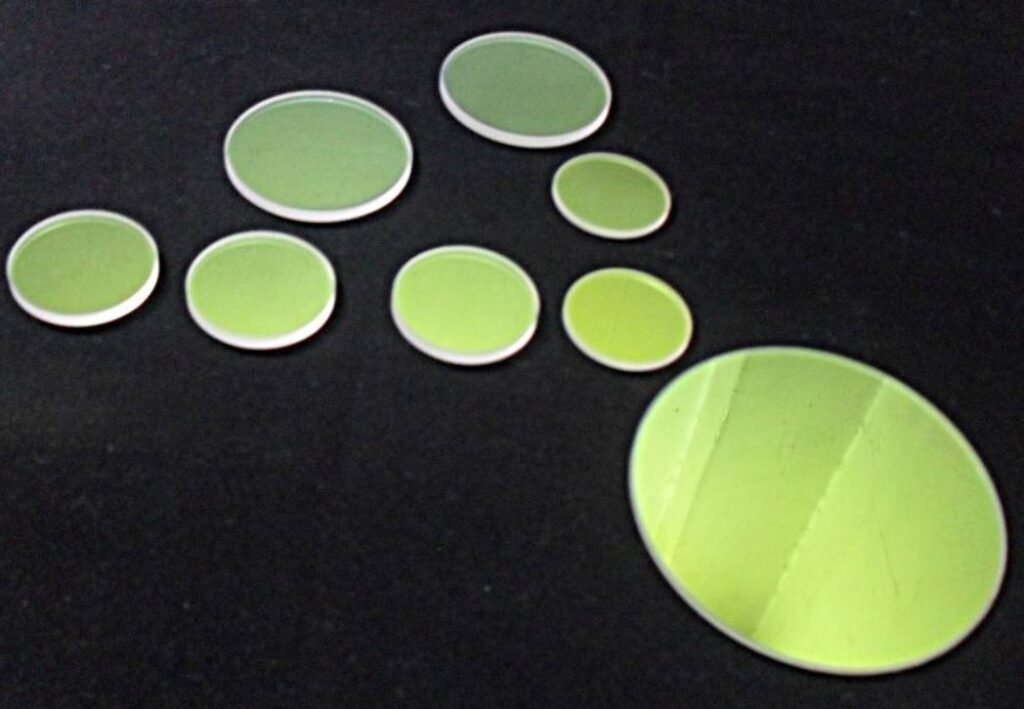

The laser cutting machine lens includes focusing lens, protective lens and so on. “How to Clean Laser Lens Mirrors” This is an issue that everyone is more concerned about.

The optical lens in the laser system is a consumable. It is easy to get dirty and easy to get dust. In order to extend the service life of the laser cutter, improve work efficiency, and reduce the cost of use, the lens must be cleaned in strict accordance with this specification.

4 Ways to clean laser lenses:

- 1.Blow off the float on the surface of the original part by blowing a balloon.

- 2.Use analytical grade acetone to gently clean the lens. The cleaning should be done at one time to avoid wavy ribs.

- 3.If acetone cannot remove all the dirt, use acid vinegar to clean it.

- 4.When contamination and lens damage cannot be removed and removed, the only way to restore good performance is to replace the lens.

How to Clean Laser Lens Precautions:

1. Be sure to wear finger cots or rubber gloves to install the lens.

2. Sharp instruments are forbidden to avoid scratching the surface of the lens.

3. Take the edge of the lens when taking the lens to avoid touching the film. The environment for testing and cleaning the lens must be dry and clean.

4. The workbench must maintain several layers of clean tissue and several clean lenses.

5. Do not speak above the lens, and keep potential contaminants (such as food, beverages, etc.) away from the work environment.

Clean laser mirrors cleaning and maintenance

Lens Cleaning Precautions

Optical lenses cannot be contacted by hand to prevent pollution. If pollution should be cleaned with high-purity alcohol in time, laser lenses cannot be washed with water, which will damage the lens. The lens cannot be placed in a humid place. It cannot be used.

Step of cleaning lenses

1. Use a blower to blow off the dust on the surface

Put the lens paper flat on the surface of the lens, drop 2 to 3 drops of high-purity alcohol, pull out the lens paper horizontally toward the operator, and repeat the above actions until the mirror surface is clean.

If the mirror surface is dirty, fold the lens paper in half 2-3 times and repeat the operation until the mirror surface is clean.

2. Clean the lens with a cotton swab:

Blow off the dust on the mirror surface with a spray gun, dip a clean cotton swab with high-purity alcohol, and use it on the centre of the lens along the circumference. After wiping a circle, replace it with a new cotton swab. Repeat several times until the lens is clean.

Take the cleaned lens to a place with better light. If the reflection of the lens is regular, it means that the mirror surface is clean. Otherwise, continue to clean.

When using the machine, the lens should be cleaned and operated correctly, so that its life and performance will undoubtedly be significantly improved. This is also one of the ways we guarantee the life and stability of the laser cutter. More prevention and maintenance can make Laser cutter work longer and have higher stability, which brings more benefits to manufacturers.

Article source: laser.ofweek.com