In the field of industrial manufacturing, laser cutting machine is a very important process that can cut various materials into various patterns. A wide variety of materials are used in the process of metal laser cutting machines, including metals and non-metals.

This article will revolve around the laser cutting materials list for you to choose the best laser cutting materials.

Learn about Laser Cutting Machines

What is laser cutting?

Fiber laser cutting machines use the heat generated by lasers to cut materials. Generally, the optical principle is used, and the CNC computer display screen is used to process the material through melting, burning, evaporation and other processes to achieve the purpose of cutting.

Advantages of laser cutting machines

- Compared with the traditional cutting process, the later secondary processing process is reduced;

- Fast speed and high precision can improve work efficiency and save costs for enterprises;

- The cutting graphics are not limited and any image can be cut;

Guide of Best Materials to Laser Cut

There are many types of laser cutting machines on the market, not only can they cut metals, but also non-metallic equipment. The following article lists the best materials to laser cut and

which materials are safe for laser cutting. Now continue reading.

Metallic material:

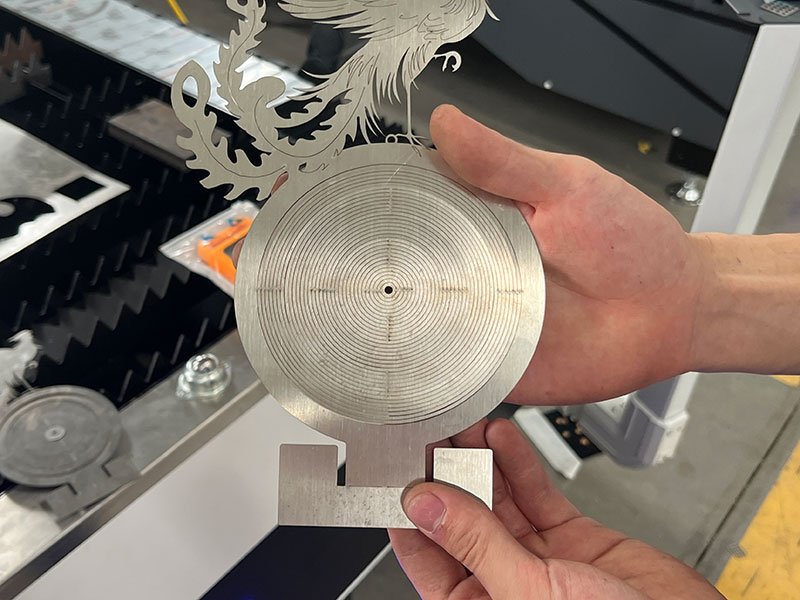

Fiber laser cutting machines are generally used for cutting metal materials to cut metal plates and pipes. Common metal laser cutting machines include fiber laser cutting equipment and CO2 laser cutting machines. The cutting effect is related to the laser power, fiber laser, thickness of the cutting plate, etc.

Fiber laser cutting equipment can cut brass, stainless steel, carbon steel, aluminum plates, nickel and tungsten plates. In addition, some auxiliary gas, nitrogen or argon, is required during cutting, which needs to be determined according to the condition of the plate.

Carbon steel plate

At present, the thickness of carbon steel plates on the market can reach 200mm, which requires high-power metal cutting equipment of 10,000 watts. The thinnest plates can be as thin as 0.1mm. Especially when cutting low carbon steel, the cutting surface is smooth and flat, and the heat affected zone is small.

Stainless steel:

For stainless steel plates, the thickness can be cut up to 6mm. The higher the power, the thicker the cutting thickness, and the better the laser cutting effect. YAG laser cutting equipment can also be used.

Aluminum:

Because aluminum is a high-gloss material, when laser cutting, you need to use a highly reflective fiber laser. In addition, auxiliary gas is required for cutting.

Alloy steel:

The laser cutting machine has good quality when cutting alloy steel, but there will be a certain amount of slag when cutting tungsten.

Brass and other metal materials:

Brass, like aluminum plate, is a highly reflective material and requires the use of a highly reflective laser.

Non-metallic materials

Plexiglass, acrylic, two-color boards, plastics, leather, fabrics, wood, etc. all require the use of CO2 laser cutting machines.

Cardboard:

Laser cutting cardboard is generally used in the advertising or packaging industries, on exquisite decorative items or wedding invitations, with high precision and beauty.

Because cardboard is flammable, it needs to be in a well-ventilated environment when cutting.

Plastic products:

Transparent plastics such as acrylic, PMMA and Lucite can ensure a good edge finish when laser cutting. Diode laser cutting equipment and CO2 laser cutting systems are required.

Cutting power, thickness, and light frequency all have an impact on the cutting effect, because plastics will produce toxic gases, which have an impact on health, so health protection measures must be taken.

Polyacetal:

A relatively common material in the engineering field, it has high strength and stable performance. Can be used in gears, guide and sliding components, medical equipment, food packaging, etc. The co2 laser cutting system is better and can also be used for engraving.

POM is toxic when charred and requires similar laser setup as acrylic. Certain settings for the blower are also required.

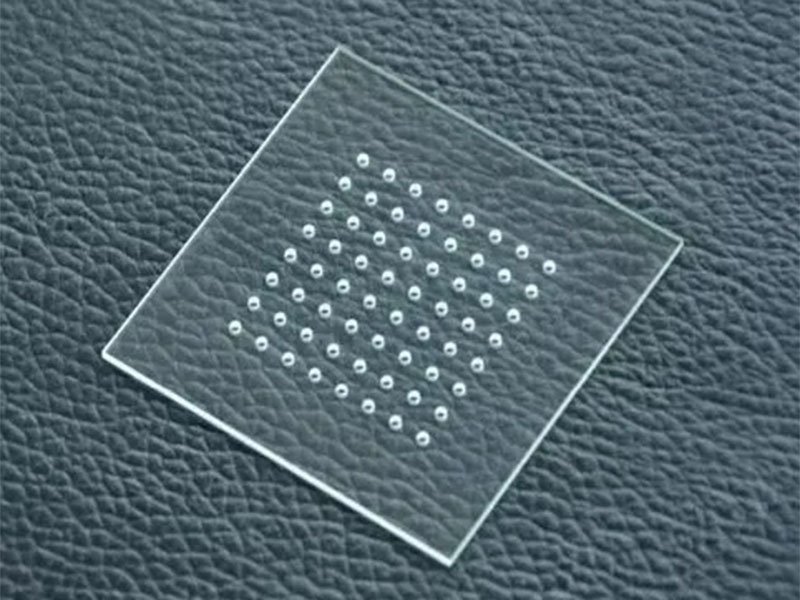

Glass:

Everyone knows that glass is fragile and reflective, and it can also be laser cut.

What Is the Cheapest Material to Laser Cut

Choosing from these materials helps keep costs low, especially when working on large projects or prototypes. Cardboard and plywood are often the go-to options for cheap, versatile laser cutting.

| Material | Cost | Uses | Laser Cutting |

|---|---|---|---|

| Cardboard | Very cheap or free (recycled) | Prototyping, packaging design | Cuts easily with low power |

| Paper | Inexpensive | Custom cards, decorations, artwork | Requires low power; be cautious to avoid burning |

| Plywood (Thin) | Cheaper than hardwood | Models, furniture, decorative items | Cuts well but can burn easily; thin layers recommended |

| MDF (Medium-Density Fiberboard) | Very affordable | Furniture, signage, crafting | Cuts cleanly but produces smoke, requires ventilation |

| Acrylic (Thin Sheets) | Relatively affordable | Signs, displays, art projects | Cuts smoothly with polished edges |

| Fabrics (Cotton, Felt) | Inexpensive | Custom clothing, fashion accessories, textile art | Cuts quickly; felt is very affordable |

| Cork | Fairly cheap | Coasters, bulletin boards, decorative items | Soft and cuts easily with low power |

| Chipboard | Low-cost | Prototypes, crafts, packaging | Cuts easily but edges can be rough if too thick |

| Leather (Faux or Thin) | Faux leather is cheaper than genuine | Accessories, custom wallets, décor | Thin or faux leather cuts well and is affordable |

Where to Buy Laser Cutting Materials

1.Local Hardware and Craft Stores

- Home Depot or Lowe’s (for wood, acrylic sheets, and metals).

- Michaels or Hobby Lobby (for thinner materials like paper, cardboard, and fabrics).

2. Online Marketplaces

- Amazon: A wide variety of laser-compatible materials, from wood sheets to acrylic, leather, and metals.

- eBay: Both new and used materials, ideal for bulk purchases or hard-to-find items.

3. Specialty Laser Cutting Material Suppliers

- Trotec: Offers a broad selection of laser cutting materials such as woods, acrylics, and textiles.

- Inventables: Specializes in materials like wood, acrylic, and more tailored for laser cutting and CNC machines.

- Ponoko: Provides laser cutting services along with material sales for acrylics, woods, and other sheet materials.

4. Industrial Suppliers

- McMaster-Carr: Supplies a wide range of industrial materials including metals, plastics, and rubber.

- Online Metals: Ideal for various metals like aluminum, steel, copper, and brass, perfect for laser cutting.

5. Wholesale Distributors

- Uline: Offers bulk paper, cardboard, and packaging materials.

- Piedmont Plastics: Specializes in plastic materials like acrylic, PETG, and polycarbonate sheets.

6. Local Metal Shops or Fabricators

- Many local metal suppliers sell small quantities of sheet metal (stainless steel, carbon steel, aluminum) which are suitable for laser cutting.

7. Maker Communities and Fab Labs

- MakerSpace or Fab Labs: Sometimes sell materials to members, and it’s also a great place to get recommendations for local suppliers.

What Materials Should Not Be Cut with a Laser Cutter

Polyvinyl chloride (PVC) and vinyl:

Release harmful gases such as chlorine during cutting, which is harmful to health and can damage parts of the laser cutter.

Polycarbonate (PC) (thickness over 1mm):

Poor cutting effect, easy to melt or burn, and produce dangerous gases when cutting.

ABS plastic:

Flammable when cutting, produces toxic gases, and may cause the cutter to clog after melting.

Fiberglass:

Contains epoxy resin, which releases toxic fumes when cutting, and the laser may not be able to cut the fiber part smoothly.

Foam materials (such as polyurethane foam):

Extremely flammable, and produce toxic fumes when cutting, which is very risky.

Factors to Consider When Using Different Laser Cutter Materials

Laser parameters:

- Power size: Under normal circumstances, insufficient or too high laser power will not achieve the desired effect.

- Laser wavelength: Different materials absorb different wavelengths of laser light differently.

- Focus position: Incorrect focus position may result in poor cutting results.

Cutting speed:

Cutting speed has a great influence on the cutting effect.

Cutting materials:

Different materials have different corresponding reflection effects and thermal conductivities, which will affect the cutting effect;

Material surface: If there is a coating, it will be difficult to cut.

Auxiliary gas:

Different auxiliary gases (such as oxygen, nitrogen, air, etc.) will affect the cutting effect and speed.

Cutting technology:

The cutting path and cutting method (such as continuous wave cutting or pulse cutting) also affect the cutting effect.

Positioning accuracy:

The repeated positioning accuracy and mechanical accuracy of the equipment directly affect the cutting accuracy.

Conclusion

This article mainly introduces materials that are safe to laser cut, not just metal materials and non-metal materials. If you want to know more about the cheapest material to laser cut

, you can consult DOWELL LASER for details.

FAQ

Can all materials be laser cut?

NO. Not all materials can be laser cut. PVC will produce toxic smoke, which is harmful to the body. In addition, ABS, high-density polyethylene and other plastics are prone to produce slag during the laser cutting process. When choosing laser cutting, be sure to consider the compatibility and safety of the materials being processed.

What are the advantages of laser cutting equipment?

- High precision: Laser cutting equipment has high cutting precision. Compared with traditional cutting methods, it does not require secondary processing and has less hair residue;

- Fast speed: different powers have different speeds;

- Wide range: suitable for cutting a variety of materials, both metal and non-metallic;

- Non-contact: no damage to materials;

- Flexible: Any graphics can be cut without restrictions.

How to choose the right material?

- Compatibility: Ensure that the cutting material can absorb the light source and improve cutting efficiency;

- Material thickness: Different materials have different thicknesses and different absorption abilities of light sources;

- Material properties: hardness, reflection, etc.

How to ensure laser cutting effect?

- Parameter settings: Set reasonable laser power, speed, and focus position;

- Selection of auxiliary gas: Different auxiliary gases have an impact on the cutting effect;

- Regular maintenance: If the equipment is old, it will be difficult to ensure accuracy during use;

- Training of technicians: Operators should operate according to the safe operation manual

Laser operating safety guidelines:

- Wear laser goggles: The strong light produced by laser is harmful to human eyes, so protective measures are required;

- Do not touch the skin with the laser: the laser energy is too high and will penetrate the skin;

- Routine maintenance of equipment: Regular maintenance and protection of equipment;

- Work area safety protection: The work area is clean and free of debris;

- Comply with operating procedures: technicians follow the laser operating manual during operation.