The more common cleaning and rust removal methods in the industrial market are laser cleaning and sandblasting. Both are often used for the treatment of steel structure surfaces. What is the difference between laser cleaning vs sandblasting? This article will describe in detail.

Working principle

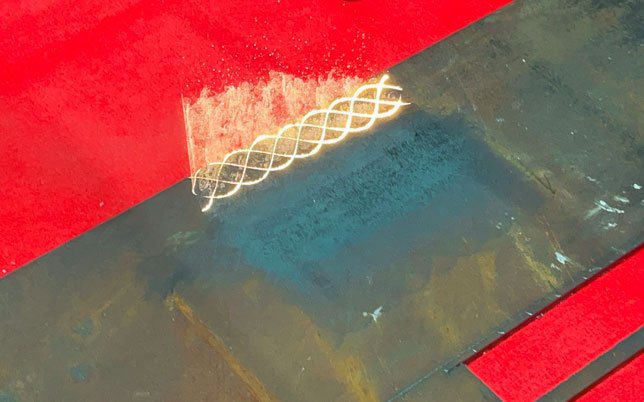

Laser cleaning

The non-contact cleaning method uses the high-energy heat generated by the laser to illuminate the surface of the substrate, quickly removing contaminants and surface oxides and impurities.

For environmentally friendly, it will not pollute the environment, protect the substrate from deformation, and achieve thorough cleaning results.

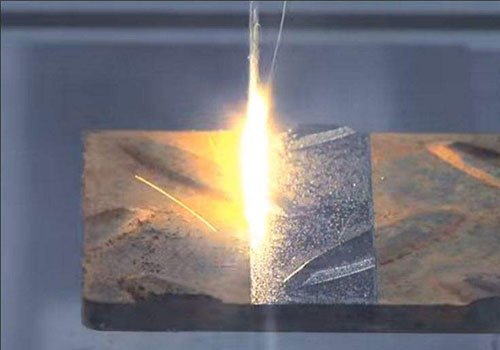

Sandblast cleaning

Mechanical cleaning method uses high-pressure air or water to push quartz sand and steel sand to grind the surface of the object, so as to achieve the purpose of removing impurities and oxide layers and cleaning.

Suitable for coarse pollutants, such as paint, oxides, etc. After cleaning, the surface roughness becomes higher, which is easy to cause surface damage.

Application field

Laser cleaning is widely used in semiconductor, electronics, automotive, aerospace, and other fields, as well as in applications requiring high precision and high requirements.

Laser sandblasting application fields include metal processing, construction, automotive, machinery and equipment.

Cost

The price of a laser cleaning rust remover varies depending on the power, brand, and performance, with equipment costs roughly in the tens of thousands.

The cost of sandblasting rust removal equipment is mainly in the maintenance of the equipment, and the price of sandblasting machines is relatively low, generally between thousands and tens of thousands.

The cost of laser cleaning equipment is higher than that of sandblasting in the short term, and in long-term use, the cost of laser rust removal equipment is lower than that of sandblasting rust removal.

Consumables cost

The cost of consumables for laser rust removal is almost zero, and laser rust removal does not require the use of any cleaning liquid or other chemical solution, nor does it require the use of any physical medium.

Laser sandblasters need to constantly replenish physical media such as steel shot or quartz sand, and these physical media will continue to consume and damage during use. Each square meter consumes about 8 kilograms of sand, about 2.2 yuan.

The cost of consumables for laser derusting is much lower than that for sandblasting.

Energy consumption

The energy consumption of laser rust removal mainly depends on the electricity cost. According to the calculation of different power lasers and different cleaning efficiencies, the electricity cost per square meter required for laser rust removal is between 0.5 yuan and 2 yuan.

The energy consumption of sandblasting and rust removal is mainly in the compressed air. According to the calculation of different pressure and flow rate air compressors and different cleaning efficiencies, the electricity cost per square meter is about 22KW and 22 kWh. According to 1.5 yuan per unit of electricity, the electricity cost is about 33-40 yuan.

Artificial

Both laser rust removal and sandblasting rust removal require certain manual operations. Laser rust removal can be operated by one person, making it easier to achieve automation and intelligence.

Laser rust removal can save more human resources and time costs.

Cleaning and rust removal intensity

Laser rust removal can achieve remote cleaning and large-area cleaning.

Sand blasting and rust removal requires manual hand-held spray gun or fixed spray gun to scan the surface of the workpiece.

Service life

The lifespan of laser cleaning is generally more than 5 years, and there is no need to replace parts during use, resulting in lower maintenance costs.

The lifespan of a sandblasting machine is relatively short, generally around 2 years. During use, it is necessary to continuously replace the nozzle, pipes and other wearing parts, and the maintenance cost is relatively high.