Laser cleaning machines are currently a relatively cutting-edge technology in the industrial market for cleaning and removing oxides, paints, and coatings on the surface of substrates. The difference between burst laser VS pulsed laser VS continuous wave is a topic that many people are paying close attention to.

There are two main types of laser cleaning machines on the market: pulsed lasers and continuous wave lasers (CW lasers).

Burst Laser VS Pulsed Laser Cleaning Machine

Principle:

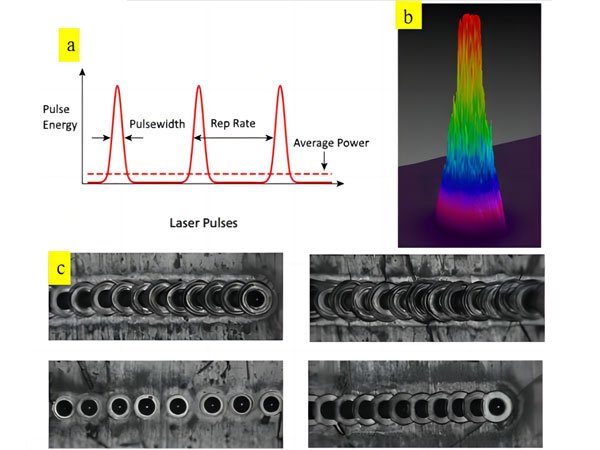

Burst Mode Laser: Consists of a relatively short sequence of high-intensity pulses with a burst duration of approximately milliseconds and a long recovery time between bursts (several seconds)

Pulse laser: generates high-energy short pulses through laser dielectric discharge, uses external Q-switched components to control the pulse time, and converts high-power broadband pulses into high-peak short pulse output through Q switches.

Destructive:

Pulse does the most damage per shot, generates the least heat, and uses the least power. Able to hit shots at a lower rate of fire.

Burst laser elite dangerous has a higher rate of fire and the best damage per second, between pulse weapons and beam weapons. They are more versatile all-purpose laser weapons.

Power consumption

The difference between pulse vs burst lasers is very small. Burst is a burst of three shots, pulse is a single shot. Easy to control with minimal heat load.

The beam emits a continuous beam, which consumes more power.

Energy consumption

The damage caused by the beam is greater than the damage caused by the burst, and the damage caused by the elite dangerous burst is slightly greater than the damage caused by the pulse.

Beams consume more energy than bursts, and bursts consume more energy than pulses.

Pulse is better in terms of damage/energy, beam is better in terms of damage/time (until you run out of weapon energy).

Cost aspect

Pulse laser: lower cost, higher dpe, higher efficiency, lower power consumption, lower heat

Burst Laser: More expensive, more heat, better than hull, higher dps, less efficient, more power consumption

Continuous Wave Laser VS Pulsed Laser

Working principle:

Pulse laser: a laser whose energy is highly concentrated in time, and its output is discontinuous. Its pulse width (ie, laser duration) is usually only a few nanoseconds or even shorter. A laser whose single laser pulse width is less than 0.25 seconds and which only works once every certain interval.

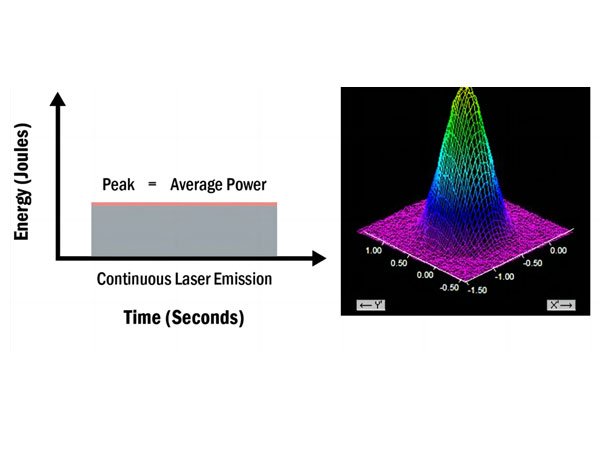

CW laser: The laser pump source continuously provides energy, with constant output power and continuous laser output for a long time. After frequency stabilization, a very narrow line width can be obtained, which can be used for laser ranging and fine spectrum.The number of particles at each energy level in the continuous laser and the radiation field in the cavity have stable distributions.

Peak

The better semiconductor lasers among continuous lasers can achieve the order of hundreds of watts, while pulsed lasers can now achieve the order of TW in femtoseconds. The shorter the pulse width, the less the thermal effect. Pulse lasers are used in fine processing. More.

Peak power = single pulse energy/pulse width; average power = single pulse energy * repetition frequency.

Energy output method

Continuous laser: The laser output by a continuous laser is stable and continuous, the power does not fluctuate violently, and the output power is relatively low.

Pulse laser: Pulse laser outputs laser light in the form of pulses, and its laser energy is concentrated and released in a very short period of time. The output power is relatively large.

Yttrium aluminum garnet (YAG) laser, ruby laser, sapphire laser, neodymium glass laser, etc. among solid lasers. There are also nitrogen molecular lasers, excimer lasers, etc.

Application:

Continuous laser: used in applications that require stable, continuous and continuous laser energy, such as optical measurement of instruments, material processing, laser cleaning,

Pulse laser: Fields that require high peak power and fast response time, such as lidar, ranging, fiber optic communications, laser marking, laser processing, and laser medical applications.

Operating hours

CW lasers can operate for long periods of time, but depending on the object they are used on, this can create heat-related issues and may even deform the object they are used on.

Pulsed lasers avoid these problems. Since it does not run continuously, it is suitable for cutting and marking without damaging the product. The disadvantage of this is that it requires more maintenance and consumables.

Horizontal output power:

Continuous lasers usually have continuous output power, while pulsed lasers have pulse output power.

Acoustic and optical nonlinearity

The effect of pulsed laser inside the material is a nonlinear and irreversible process, and it has properties that continuous laser does not have, such as high peak power and high peak energy.