Copper sheet is an essential metal plate in the industrial market. Cutting copper is a headache for many business owners because copper is a highly reflective material that reflects infrared light and affects the absorption of laser beam energy.

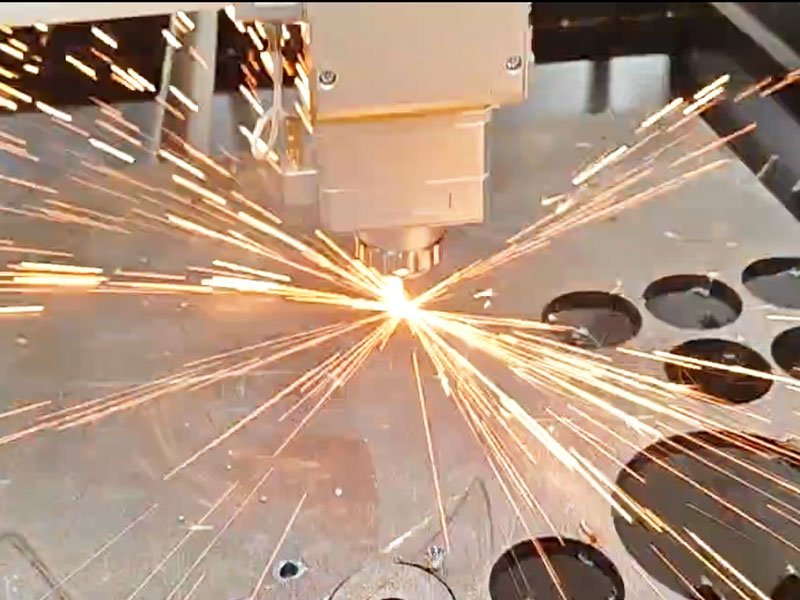

What is copper laser cutting?

Fiber lasers have a more easily absorbed wavelength of approximately 1.07 µm, while traditional CO2 emits at a wavelength of 10.6 µm. Cutting copper can be difficult with CO2 lasers or infrared lasers. Fiber lasers can provide higher power density, making metal penetration easier.

Why choose laser cut copper sheet for the industrial market?

Copper is used in industrial manufacturing because copper has thermal conductivity, electrical conductivity, and corrosion resistance relative to other sheets, which are its unique characteristics. Most of them are used in wire production and construction production.

Highly reflective materials, whose reflectivity can usually reach more than 80% or even 90%, have rich colors and color diversity, and can achieve ideal optical effects. Highly reflective materials are widely used in industry, such as lighting, imaging, aerospace and military fields.

What use to cut copper sheet

There are many tools and methods for cutting copper on the market. Traditionally, CO2 lasers are used, but this requires spraying chemicals on the copper surface and placing reflections. Long-term use will cause damage to the laser. With the birth of fiber lasers, laser cutting copper has become It is simple and efficient, gradually replacing the use of CO2.

Advantages of laser cut copper

Compared with traditional cutting methods, the thickness of cutting materials is not limited, which is beneficial to improving production efficiency and saving costs for enterprises.

The efficiency of laser cutting copper plates is higher, 3 times that of traditional cutting, saving labor and easy to operate.

The cut images are not restricted and can be cut arbitrarily, which is more convenient.

What other reflective metal materials are there?

Metal:

copper, silver, gold, etc.;

Non-metals:

magnesium, silicon, silicon carbide, etc.

Many metallic materials can be used to make highly reflective materials, such as metallic copper, silver, gold, etc.

Because electrons and holes propagate very quickly, metals have greater reflectivity in the visible light band and smaller reflectivity in the infrared band.

What’s more, the infrared emissivity (or absorptivity) of a metal is closely related to its composition and structure. For example, aluminum and magnesium are very important highly reflective materials. These two materials have the same composition and structure, but they have different reflectivities in the infrared band.

Can you laser cut copper

Fiber laser cutting machine can cut copper. You need to pay attention to the following points:

- Copper is conductive and will absorb more energy from the laser. You need to choose a laser cutting machine with higher power.

- The melting point of red copper is low, and the laser cutting machine needs better energy control and flow control functions to ensure stability and efficiency during the cutting process.

- Copper is easily oxidized, so oxidation protection measures must be taken. Operators also need to take corresponding safety measures to avoid safety accidents caused by improper operation.

- If high-precision cutting and engraving are performed on copper, the accuracy of the laser cutting machine must also be taken into consideration to ensure the accuracy of the cutting quality and effect.

What gas is used for laser cutting copper plates?

Copper and brass are also highly reflective and thermally conductive materials.

- Brass with a thickness less than 1mm can be cut with nitrogen laser cutting;

- For copper with a thickness less than 2mm, oxygen must be used for laser cutting.

Install a “reflection absorption” device on the fiber laser cutting machine system to prevent the laser cutting machine from damaging components when cutting copper and brass!