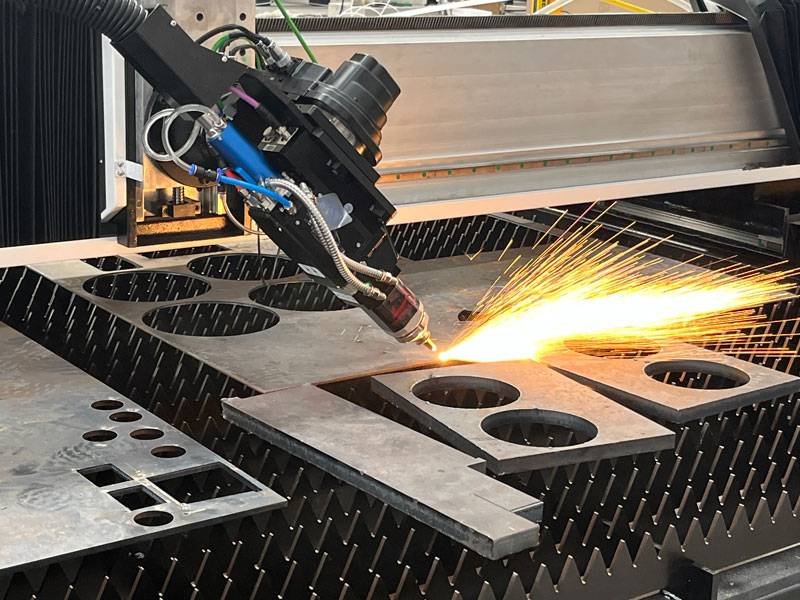

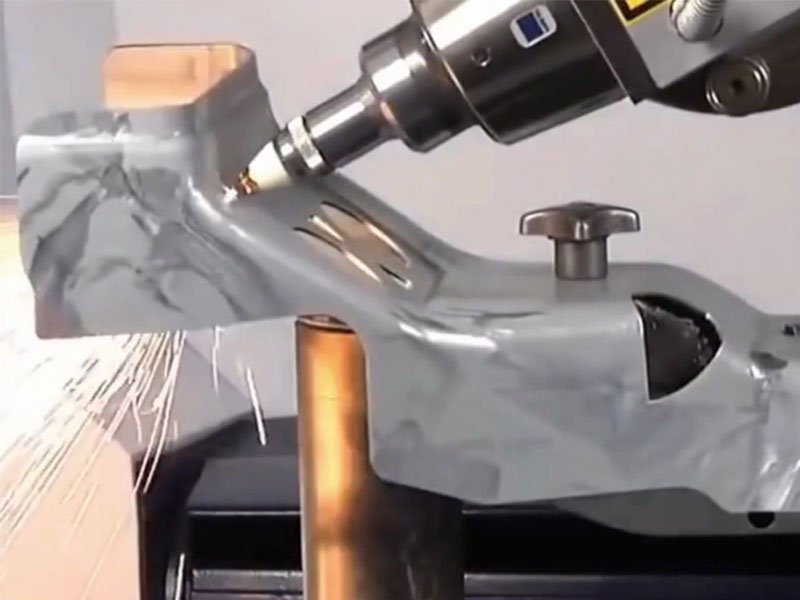

With the rapid development of the industrial market, traditional laser cutting cannot meet the multi-dimensional cutting effect. The advent of the three-dimensional five-axis laser cutting machine has solved the problem of multi-dimensional cutting very well. The 5-axis cutting head adopts fully automatic infinite rotation. Structure, can achieve 360° bevel cutting. This cutting process can perform various bevel cuts on steel plates: A-type, V-type, Y-type, and X-type.

I hope this article can provide you with some suggestions and references when selecting a 3D five-axis laser cutting machine, and help your enterprise choose the most suitable and valuable equipment.

What is a 5 Axis Laser Cutting Machine

3D 5 Axis Laser Cutting Machine adopts a three-dimensional five-axis cutting system based on traditional laser cutting equipment to achieve a maximum 45° bevel cutting on the plane. The processing width can be customized at will, which greatly improves the efficiency of sheet metal processing.

Instead of traditional processing methods such as punching dies and trimming dies, it can process a wide range of materials like stainless steel, mild steel, aluminum, brass, and copper with high precision and efficiency.

How Much is A 3D 5 Axis Laser Cutting Machine Price

The price of a 3D 5-axis laser cutting machine can vary greatly depending on factors such as brand, size, specifications, and additional features. Generally speaking, high-end industrial-grade machines range in price from $30,000 to $100,000 or more. It is recommended to contact the

5 Axis Laser Cutter Application

Automobile manufacturing, mold manufacturing, aerospace, rail transit, and other industries, especially in the processing of automotive thermoformed parts, have shown strong processing advantages. Compared with the traditional processing mode, the production efficiency has been increased by 3-5 times, and the efficiency can be described as a qualitative leap.

Factors Influencing the Price of 5 Axis Laser Cutting Machines

The price of a 5 axis laser cutting machine can vary significantly based on several factors. Understanding these factors can help buyers make informed decisions and choose the right machine for their needs.

1. Laser Power and Type

- Laser Power: The wattage of the laser is one of the primary determinants of price. Higher power lasers can cut thicker materials and do so faster, but they are also more expensive. Typical power ratings for 5-axis laser cutting machines range from 2 kW to 6 kW or more.

- Laser Type: The type of laser, such as CO2, fiber, or diode, also affects the cost. Fiber lasers, known for their efficiency and lower maintenance requirements, are generally more expensive than CO2 lasers.

2. Machine Size and Build Quality

- Size of the Cutting Area: Larger machines with bigger cutting areas can handle more extensive workpieces, which typically translates to a higher price.

- Build Quality: Machines made from high-quality, durable materials that ensure longevity and reliability will cost more. Additionally, advanced features like rigid machine frames to minimize vibrations can also drive up the price.

3. Advanced Features and Technology

- Software and Controls: Advanced software that offers user-friendly interfaces, real-time monitoring, and automated adjustments can significantly increase the machine’s cost.

- Additional Features: Features such as automated material handling, enhanced cooling systems, and advanced safety features also add to the overall price.

4. Brand and Manufacturer

- Brand Reputation: Established brands with a reputation for quality and reliability often charge a premium for their machines. Brands like TRUMPF, Bystronic, and Mazak are known for their high-quality 5-axis laser cutting machines but come at a higher cost.

- Manufacturer Location: Machines manufactured in regions with higher labor and production costs will generally be more expensive.

5. After-Sales Support and Service

- Warranty and Maintenance: Comprehensive warranties and maintenance packages add to the initial purchase price but provide peace of mind and long-term savings.

- Training and Technical Support: Manufacturers that offer extensive training and ongoing technical support typically charge more for their machines.

How to Choose the Right 5 Axis Laser Cutting Machine Factory

Selecting the right 3D five-axis laser cutting machine requires considering many factors. In practical applications, a full understanding of the requirements of material type, machining accuracy, etc. can help to more clearly select the equipment that best meets the needs. In addition, equipment brands, after-sales services, etc. also need to be carefully measured.

Choose the right 3D 5 Axis Laser Cutting equipment

- Cutting material type: First consider whether the cutting machine is suitable for the type of material expected to be cut. For example, some laser cutting machines are suitable for metallic materials, while others are suitable for non-metallic materials. Understanding the range of materials supported by the laser cutting machine can provide you with the first step of screening.

- Cutting thickness: According to the thickness of the cutting material, select a laser cutting machine with corresponding cutting capabilities. Different laser equipment has different powers and cutting capabilities. Make sure the laser cutting machine you buy can meet the maximum thickness requirements of the processing.

- Cutting accuracy and quality: Understand the cutting accuracy and cutting quality of laser cutting machines. Based on your actual application needs, choose a laser cutting machine that meets accuracy and quality requirements.

- Production efficiency: If you pay attention to production efficiency, you can choose a faster laser cutting machine. High-speed laser cutting machines often improve production efficiency due to the use of more technologically advanced lasers and drive systems.

- Laser type: According to the application requirements, select the appropriate laser type, such as solid-state laser, gas laser, fiber laser, etc. Different types of lasers have their own advantages and disadvantages, choose according to your actual needs.

- System functions: Consider the required system functions, such as automatic table changing, automatic focusing, anti-collision protection, etc. These functions may affect the convenience of operation and production efficiency.

- Budget and Cost: Budget and cost are also an important factor to consider. With the same functions and performance, you can compare the prices of laser cutting machines of different brands and models and choose equipment with higher cost performance.

- After-sales support and service: Choose a manufacturer that provides good after-sales support and service, which can help you solve problems and maintenance needs you may encounter during subsequent use.