Water Jet Laser Cutting Machine is a new type of metal processing technology that perfectly combines water shooting technology with laser technology on the market. This technology has high cutting accuracy and higher efficiency. It is suitable for precision processing industry fields.

Many customers are interested in this new Water Jet Laser Cutting technology. Now this article will describe detailed descriptions of Water Jet Laser Cutting Machine. I hope it will be helpful for customers who want to purchase Laser Microjet Machine.

What is Laser Microjet Cutting Machine

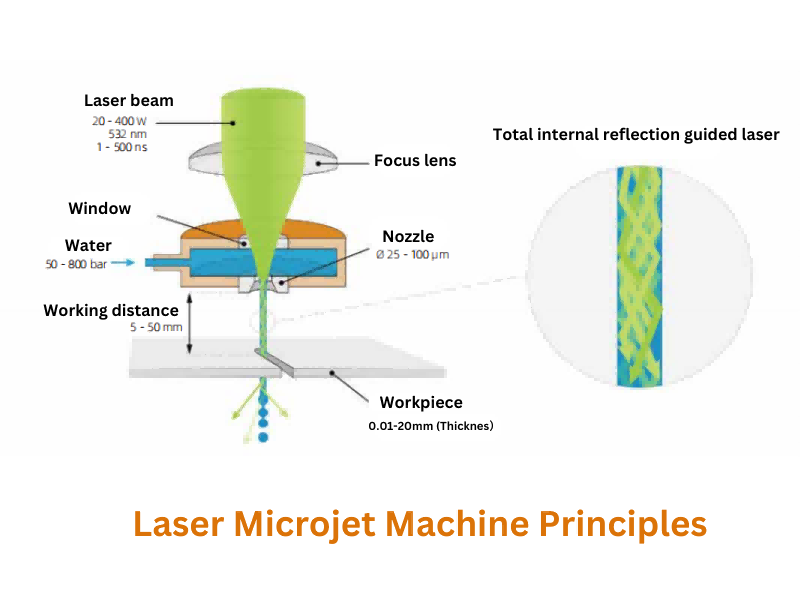

Laser Microjet Machine is also known as Water Jet Guided Laser system. The Water Jet Guided Laser cutting machine is fully reflected with ultra -pure water and air. And make the green laser beam coupled to fine water shots. Laser (using green light laser 532nm) has a high energy density and can achieve precision materials processing.

How Much Is Water Jet Laser Cutting Machine Price

The price of Laser Microjet Cutting Machine may change according to factors such as size, functions, brands, and specific functions. The current laser microjet machine price on the market ranges from $ 50,000 to $ 500,000 or more. Basic models may start from the lower end, and high -end automatic systems with advanced functions may be more expensive. If you want to know the specific Water Jet Laser Cutting Machine Price, it is best to contact the manufacturer or supplier according to your specific requirements to obtain the offer.

Laser Cutting vs Water Jet Cutting

Laser Cutting

- Technology: Uses a high-powered laser beam to melt, burn, or vaporize material.

- Materials: Effective on metals, plastics, glass, and wood.

- Precision: High precision with clean edges and minimal thermal distortion.

- Speed: Generally faster for thin materials and complex shapes.

- Heat Affected Zone: Minimal, but can cause warping in thicker materials.

Water Jet Cutting

- Technology: Utilizes a high-pressure stream of water, often mixed with abrasive materials, to cut through material.

- Materials: Can cut a wide range of materials, including metals, stone, glass, and ceramics.

- Precision: Slightly less precise than laser cutting but excellent for thick and hard materials.

- Speed: Slower compared to laser cutting, especially on thinner materials.

- Heat Affected Zone: None, as it’s a cold cutting process, preventing warping and thermal damage.

Choosing Between Them: Select laser cutting for high precision and speed on thin materials. Opt for water jet cutting for thicker materials and when avoiding heat damage is critical.

What Advantages Can Laser Microjet Have over Conventional Laser Machining

- The water -guided laser cutting machine does not cause heat damage, because the sprayed water can greatly reduce the thermal deformation and thermal damage of the material in the laser pulse gap cooling material, so that the material maintains its original structure;

- Water optical fiber work distance is large, and no focus is required;

- The spray water flow will take away the melting materials during the cutting process, reducing pollutants;

- The processing accuracy is higher than the traditional laser processing accuracy, and it is especially suitable for high -precision processing of thin wall parts.

Conventional laser processing vs water guide laser processing

| Optical laser processing | Water jet guided laser processing |

| Need accurate focus | Cut -shaped laser beam cut edge parallel |

| The tapered laser beam causes the processing wall to be uncomfortable | Large -length diameter ratio, can achieve the minimum material loss of the width of the cut border below 30 microns, and the darker hole can be drilled |

| Large melting layer and heat influence area | The cooling effect of water flow reduces the thickness of the heavy melting layer and the heat influence area |

| Machining waste is easy to accumulate | Water currents are rinsed with processed waste, no special protective layer is required |

| Easily lead to burrs | Bond |

Best Water Jet Laser Cutting Machine for Sale’s brand

Water jet guided laser cutting machine is a new type of laser technology on the market. The famous supplier brands on the market are as follows:

Synova: Synova is a well-known supplier of laser microjet machines, offering high-quality solutions that combine laser precision with water jet cooling. Their machines are known for their exceptional accuracy and are widely used in industries like semiconductor manufacturing, medical device production, and aerospace.

Omax Corporation: Omax is a leading supplier in the waterjet and laser cutting industry. Their laser microjet machines are designed for high-performance cutting, providing clean and precise cuts with minimal thermal damage. Omax’s machines are favored for their robustness and reliability.

GF Machining Solutions: This supplier offers advanced laser microjet technology, focusing on delivering precision and efficiency. GF Machining Solutions is recognized for its innovation and excellent customer support, making them a top choice for industries requiring high-precision cutting.

Each supplier is known for producing high -quality laser micro -machine machines, which can ensure that you get the best specific application.

If you are interested in Dowell Water Jet Guided Laser Cutting Machine Price or want to know more about Laser Microjet Machine technology, you can consult us.