When it comes to laser cutting, an air compressor is one of the most critical tools to enhance cutting quality, efficiency, and precision. By delivering high-pressure air directly to the laser, an air compressor helps clear away molten materials, cool the cutting area, and improve cutting accuracy.

Many customers will ask why air compressor for laser cutting machine, then how to choose the best air compressor for laser cutting,In this guide, we’ll dive into the essential factors for choosing the best air compressor for laser cutting, explore the types available, and share maintenance tips that will help you make an informed decision.

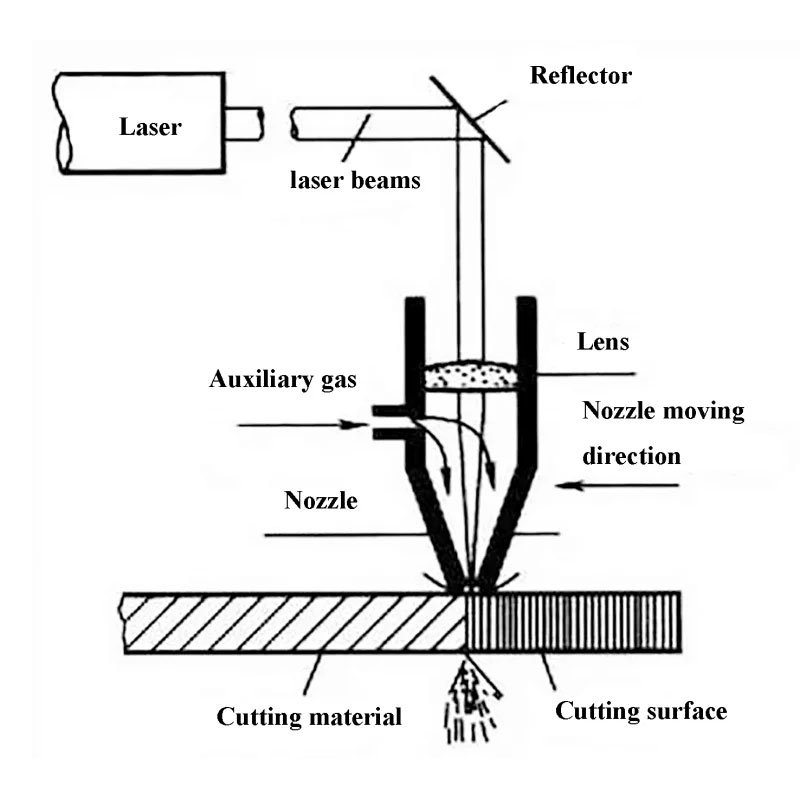

Fiber laser cutting with compressed air working principle

Air compressor for laser cutting machine plays a vital role in directing a powerful airflow to the cutting point of the laser. This airflow helps blow away excess material, reducing heat in the cutting area and maintaining a cleaner cut. With the right air compressor, you can achieve smoother, more accurate cuts while extending the life of your laser machine.

Laser cutting machines require a pressurized gas source as power when working. Commonly used auxiliary gases include oxygen, nitrogen, compressed air, and sometimes argon. According to the gas pressure, it can be divided into high-pressure gas and low-pressure gas.

With the demand for cutting plate thickness and efficiency, the pressure of compressed air has also developed from the previous 1.25MPa ~ 1.3MPa to a higher pressure, even reaching 2.0MPa ~ 3.0MPa. Currently, 1.6MPa compressed gas is mainly used in the market.

Why do we need an air compressor for laser cutting?

- An air compressor (also called an air compressor) can provide clean, dry and stable air to improve the quality and effect of cutting;

- The compressed air provided by the air compressor provides power to stabilize the workbench;

- Purge and clean the optical system and remove debris. Whether it is the impact of moisture, dust and impurities in the atmosphere on the accuracy of laser cutting, or the pollution of oil stains on the laser machine lens;

An air compressor is essential. The air compressor used for laser cutting must be deoiled and dewatered, and the quality of compressed air is also very high.

What does air assist do for laser

Importance of laser cutter air assist

The importance of air assist for laser cutter is its ability to improve cutting and engraving quality while ensuring machine and operator safety.

- Air assist helps remove debris and fumes generated during cutting or engraving, preventing them from interfering with the path of the laser beam. This results in a cleaner cut, less charring, and improved engraving detail.

- The air assist pump for laser cutter helps cool the material and laser lens, minimizing the risk of thermal damage and extending the life of the equipment.

Incorporating air assist into your laser cutter setup is critical to achieving optimal performance, maintaining safety standards and extending machine life.

Types of Air Compressor for Fiber Laser Cutters

Integrated air compressor (screw air compressor) integrates components such as air compressor, refrigeration dryer, cylinder and gas storage tank into a single frame;

Split air compressors separates the compressor main unit and the gas storage tank and connects them through pipelines to form a complete compressor system.

Integrated VS split laser air compressor

Structure

Integrated air compressor: compact structure and small size, suitable for places with small space.

Split air compressor: The structure is relatively large and requires special space for storage.

Scenes to be used

Integrated air compressor: suitable for places with small spaces, such as maintenance workshops, car repair stations, etc. Due to its compact structure and easy maintenance, integrated air compressors are commonly used in maintenance workshops and other maintenance industries.

Split air compressor: It is of higher grade and requires special space for storage and use. It is mostly used in industries that require high voltage stability and long-term continuous use, such as chemical plants, electronics The capacity of the gas tank can be selected as needed.

Remove moisture

The water removal capability of the integrated air compressor is relatively weak, and careful drainage is required to ensure its normal operation.

Split air compressors are equipped with more professional water removal equipment and have a stronger ability to remove moisture.

Repair:

Due to its compact structure, the integrated air compressor is more convenient and flexible to maintain, but it has many connecting parts that are more complicated to maintain.

Split air compressors are relatively fixed and more stable, and more difficult to maintain, but they are more suitable for sending large-capacity gas compression.

What kind of laser air assisted compressor do you need?

CO2 laser cutting machine

The power of CO2 laser cutting machines is generally between 100W-1500W, and the air compressor should be selected according to actual production needs.

- 100W-200W Co2 laser cutting machine is suitable for an air compressor of about 1.5 horsepower;

- 200W-400W Co2 laser cutting machine requires an air compressor with a power of 2.2-3.0 horsepower;

- 400W-600W CO2 laser cutting machine requires an air compressor with a power of 3.0-5.5 horsepower;

- Co2 laser cutting machines with a power of more than 600W need to use an air compressor with a power of more than 7.5-10 horsepower.

Fiber laser cutting machine

The power of fiber laser cutting machines are generally between 300W-6000W, and the air compressor should be selected according to actual production needs.

- 300W-800W fiber laser cutting machine is suitable for 2.2-3 horsepower air compressor;

- 800W-1500W fiber laser cutting machine requires an air compressor with a power of more than 5.5 horsepower;

- 1500W-6000W fiber laser cutting machine requires an air compressor with more than 10 horsepower.

Laser cutting machines of different powers require the selection of air compressors of different powers. Adequate air pressure and gas production are the keys to selecting an air compressor, and quality is also a very important factor.

Top Brands for Laser Cutting Air Compressors

Atlas Copco GA Series: Known for durability and efficiency, these rotary screw compressors are ideal for continuous use in industrial settings.

Ingersoll Rand Reciprocating Compressors: Great for small-scale operations, these compressors offer dependable performance at an affordable price.

Hitachi Scroll Compressors: Perfect for precision work, these compressors are quiet and offer oil-free air, making them suitable for environments requiring clean airflow.

How to choose best air compressor for laser cutting

Exhaust volume

The air compressor needs to provide a stable air pressure output to ensure that the pressure of the gas output is constant and to ensure the stability and continuity of the air pressure during the cutting process.

When selecting an laser air assist compressor, it is necessary to choose the appropriate pressure level according to the air pressure output required for laser cutting to avoid unstable cutting quality and low efficiency due to unstable air pressure output.

It ensures air pressure output while meeting high-flow gas output requirements. Its exhaust volume and flow rate need to be considered to ensure that it can meet the gas flow requirements required for laser cutting.

Choose an air compressor that is larger than If the exhaust volume of the air compressor is too large, much larger than the actual demand, even if the air compressor has frequency conversion adjustment, it may cause excess air supply.

In order to maintain a stable air supply pressure, the air compressor has to start running once the air consumption continues. Such frequent “start-run-sleep-start-run-sleep” can seriously cause the lubricating oil in the oil and gas separator to produce bubbles and emulsification, which will shorten the life of the air compressor and cause excessive oil content in the exhaust port. high.

Pressure

But if the laser power is not high enough, no matter how high the pressure is, it will not help. After all, the laser power is high enough to melt the cutting material faster.

Noise Level

For many operations, noise levels are an important consideration. If you’re working in a shared space, a low-noise or quiet air compressor may be preferable. Many manufacturers now offer noise ratings on compressors, so compare these if noise is a priority.

Compressed air quality

The gas used in laser cutting is usually a high-purity gas, and the quality of the gas directly affects the quality of the cutting effect.

Compressed air contains water mist and oil. If it is not treated cleanly and high-pressure is sprayed onto the protective mirror of the laser cutting head, it will seriously affect the transmission of the laser beam, disperse the focus, cause the product to be cut through, and produce waste products.

Special products launched for laser cutting machines. Usually, the micro-oil twin-screw and post-processing equipment are installed together to form a complete air source system, which we call a four-in-one laser cutting special air compressor.

Take carbon steel as an example of the criteria for selecting an air compressor for laser cutting:

| Laser Cutting Machine Power | Air Compressor Specification | Recommended Cutting Thickness (Carbon Steel) |

|---|---|---|

| Less than 1.5kw | 11kw 16kg | 2mm |

| Less than 3kw | 15kw 16kg | 4mm |

| Less than 6kw | 15kw 16kg (High Volume) | 6mm |

| Less than 10kw | 22kw 16kg | 8mm |

| 12-15kw | 22/37kw 20kg | 10-12mm |

Reliable performance and stability

The air compressor needs to have reliable performance and stability to ensure the continuity and stability of air pressure output during the cutting process, and to avoid reduction in cutting quality and efficiency caused by air compressor failure.

When purchasing an air compressor, choose according to actual needs, and choose a factory with a good brand reputation and perfect after-sales services.

Maintenance Requirements

Some air compressors require frequent maintenance, while others are low-maintenance or even maintenance-free. Consider the time and resources you’re willing to invest in maintenance when choosing between models.

How to Properly Maintain Your Laser Cutting Air Compressor

Regular maintenance is crucial for optimal compressor performance and longevity. Here are essential maintenance steps:

- Regular Inspection: Check for leaks, worn parts, and secure fittings. Regular inspections help catch potential issues early.

- Filter Replacement: Keep the compressor’s air filter clean by replacing it according to the manufacturer’s guidelines. A clean filter ensures pure air flow, which is vital for laser cutting.

- Lubrication: Oil-based compressors need regular lubrication to prevent wear. Check your compressor’s oil levels and top them off or replace them as necessary.

- Drain the Tank: Over time, moisture can accumulate inside the compressor’s tank. Draining this moisture regularly prevents rust and keeps the air compressor functioning optimally.

Compressor for laser cutting Cost

Laser cutting air compressors come at various price points, depending on power, features, and brand.

Entry-Level Compressors: $200–$600, suitable for light to moderate use.

Mid-Range Compressors: $600–$1,500, designed for small businesses or heavier use.

Industrial Compressors: $1,500+, ideal for continuous, high-demand laser cutting tasks.

Conclusion:

Selecting the right air compressor for laser cutting is essential for achieving high-quality laser cuts. From understanding pressure and airflow to choosing the right type, these factors will guide you in making a smart purchase. Consider your needs, budget, and work environment to find the air compressor that suits your laser cutting goals best.

FAQ

What size air compressor for cnc machine?

The size depends on your laser cutter’s CFM and PSI requirements. Small desktop cutters may only need 2–3 CFM, while larger industrial machines require 8–12 CFM or higher.

How does air pressure affect laser cutting quality?

Higher air pressure helps maintain cutting quality by clearing away debris, reducing heat, and ensuring precise cuts. Matching the air pressure to your material and laser power is crucial for best results.

Can I use a regular air compressor for laser cutting?

Yes, but ensure it meets the CFM and PSI needs of your laser cutter. Some compressors may not provide the clean airflow required for laser cutting, so choose one designed for this purpose.